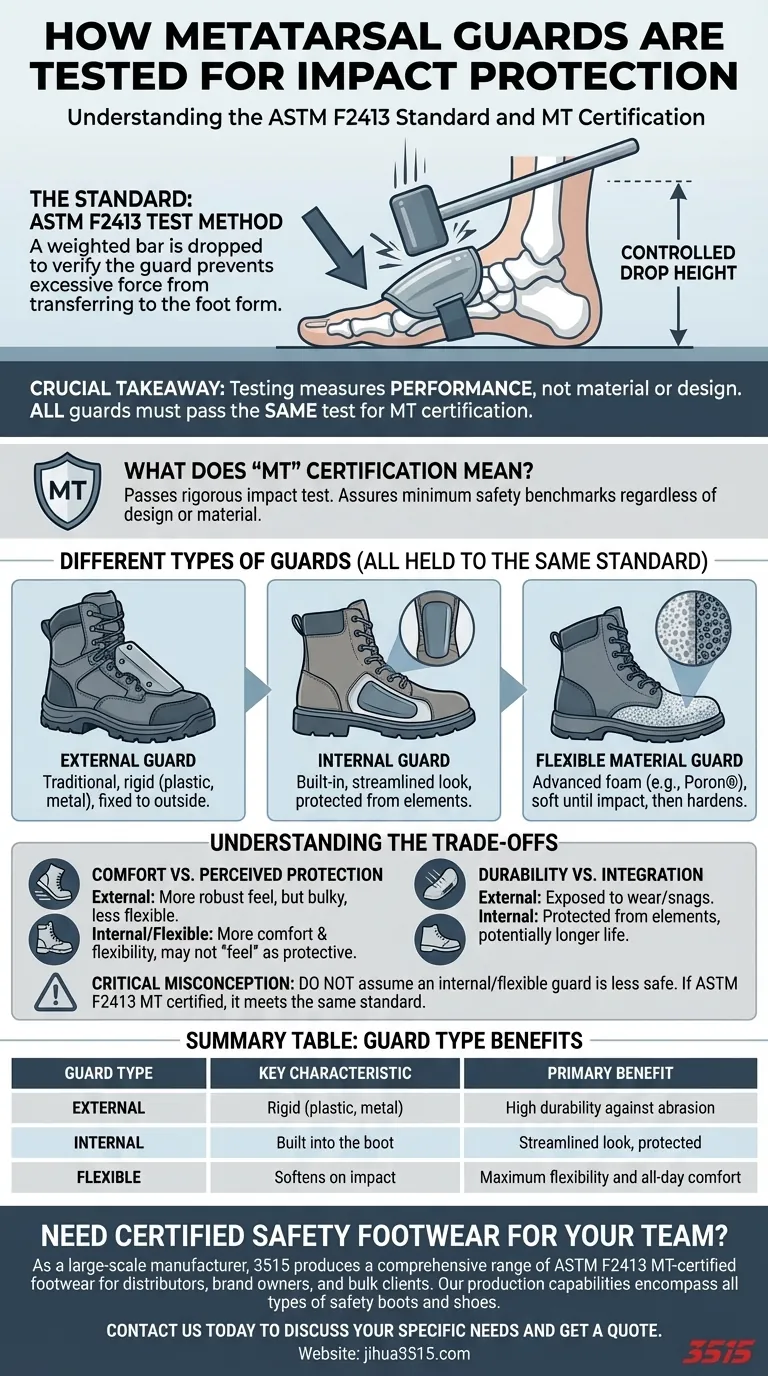

At its core, the impact protection of metatarsal guards is verified using the ASTM F2413 test method. This standard sets the industry benchmark for safety, ensuring that both internal and external guards can withstand a significant impact force to protect the top of your foot.

The crucial takeaway is that the testing method is not about the material or design of the guard, but its performance. Any guard, whether internal or external, must pass the same standardized impact test to earn the "MT" certification.

The "Why" Behind Metatarsal Guard Testing

Metatarsal guards are designed for one primary purpose: to protect the delicate metatarsal bones on the top of your foot from crushing injuries caused by falling, dropping, or rolling objects. The testing process exists to provide a reliable, objective measure of this capability.

The Standardized Test: ASTM F2413

The American Society for Testing and Materials (ASTM) F2413 is the governing standard for performance requirements for protective footwear.

Within this standard, there is a specific test for metatarsal (MT) protection. A weighted bar is dropped from a controlled height onto the guard, which is mounted on a test foot form.

To pass, the guard must prevent the impact from transferring excessive force to the foot form, effectively shielding it from the kind of impact that would cause a serious injury.

What Does "MT" Certification Mean?

When a boot is rated as "MT" under ASTM F2413, it signifies that its metatarsal guard has successfully passed this rigorous impact test.

This certification is your assurance that the guard meets the required minimum safety performance benchmarks, regardless of its specific design or the materials used.

The Different Types of Guards Under Test

While the test is standardized, the guards themselves come in various forms. The test applies equally to all of them, holding each to the same performance standard.

External Metatarsal Guards

These are the most traditional type, often made of rigid plastics, rubber, or metal. They are fixed to the outside of the boot over the laces.

Internal Metatarsal Guards

These guards are built directly into the footwear, sitting between the outer material and the inner lining. This design offers a more streamlined look.

Flexible Material Guards

Innovations like Poron® guards use advanced, open-cell foam materials. These are designed to be soft and flexible during normal wear but instantly harden upon impact to disperse energy, providing protection without the rigidity of traditional materials.

Understanding the Trade-offs

While all certified guards pass the same test, their design has practical implications for the wearer.

Comfort vs. Perceived Protection

External guards often feel more robust, but they can be bulky and less flexible. Internal guards, especially those made from modern polymers like Poron®, offer significantly more comfort and flexibility but may not "feel" as overtly protective, even though they pass the identical safety test.

Durability and Integration

External guards are exposed and can be subject to wear, tear, or snagging. Internal guards are protected from the elements, which can extend their functional lifespan and prevent them from being a hazard.

The Critical Misconception

Do not assume an internal or flexible guard is less safe than a rigid external one. If both carry the ASTM F2413 MT rating, they have both met the same critical impact protection standard.

Making the Right Choice for Your Goal

The best metatarsal guard is the one that meets the safety requirements of your job while providing the comfort you need to wear it consistently.

- If your primary focus is maximum flexibility and all-day comfort: Look for boots with certified internal guards, particularly those using advanced, flexible materials.

- If your primary focus is working in an environment with extreme abrasion or external hazards: A traditional external guard made of metal or rigid plastic may offer added durability against scrapes and snags.

Ultimately, the ASTM F2413 MT certification is the definitive mark of proven impact protection.

Summary Table:

| Guard Type | Key Characteristic | Primary Benefit |

|---|---|---|

| External | Rigid (plastic, metal) | High durability against abrasion |

| Internal | Built into the boot | Streamlined look, protected from elements |

| Flexible (e.g., Poron®) | Softens on impact | Maximum flexibility and all-day comfort |

Need Certified Safety Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM F2413 MT-certified footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes, ensuring your workforce has access to comfortable, durable, and rigorously tested metatarsal protection.

Contact us today to discuss your specific needs and get a quote.

Visual Guide

Related Products

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Grain Leather Safety Boots for Bulk Supply

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What physical protections are provided by the S1 standard and integrated steel toecaps in industrial safety boots? Ensure Ultimate Foot Safety & Hazard Protection

- Why is the use of steel-toe safety footwear critical during the maintenance of sugar factory press chains? Protect Your Team

- Why do operations involving heavy fruit bunches and 'gancu' require anti-smash and anti-puncture safety boots?

- How do abrasion-resistant work boots extend equipment service life? Maximize Durability in Harsh Outdoor Environments