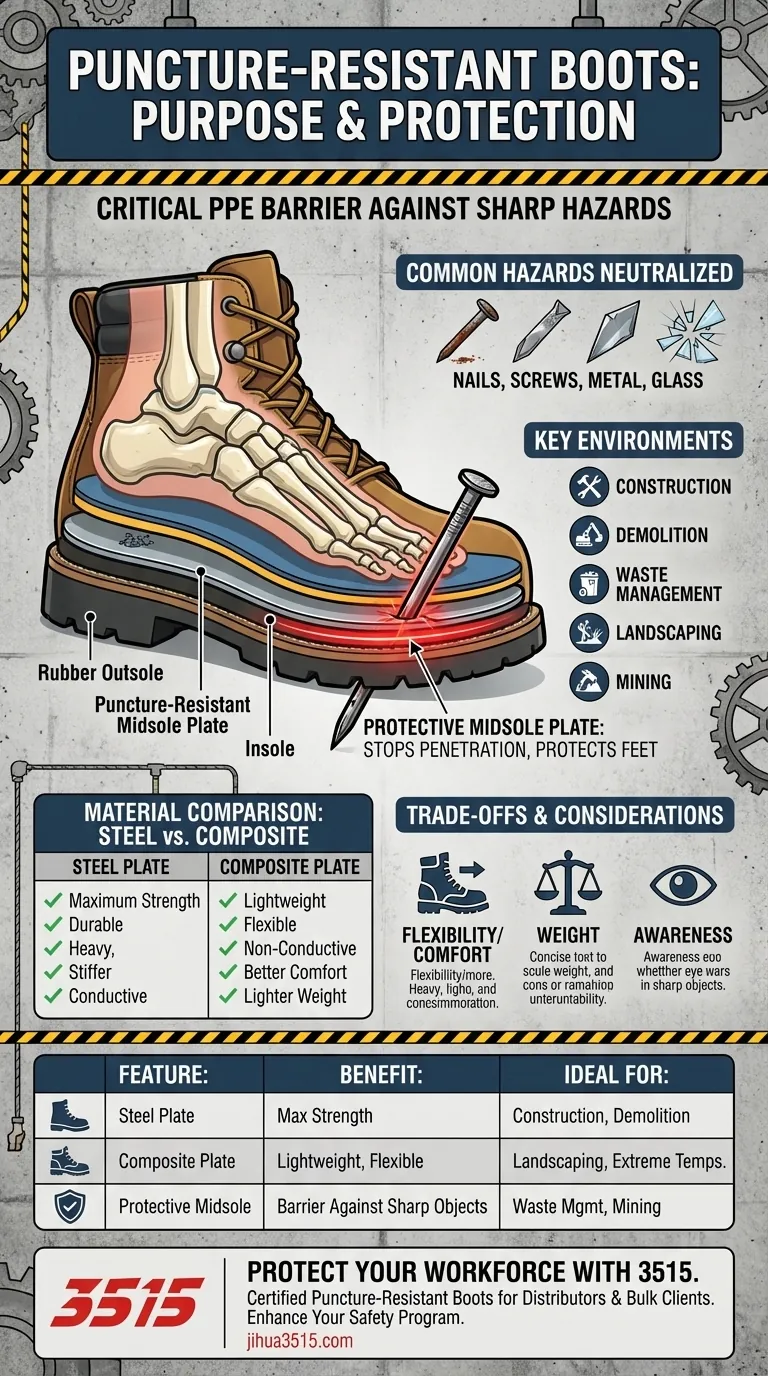

The primary purpose of puncture-resistant boots is to protect your feet from sharp objects penetrating the sole of your footwear. They achieve this by incorporating a durable, protective plate between the insole and the outsole, creating a critical barrier against hazards like nails, screws, sharp metal, or broken glass commonly found in hazardous work environments.

Puncture-resistant boots are not just a feature; they are an essential piece of personal protective equipment (PPE) designed to prevent debilitating foot injuries from unseen threats on the ground. The core principle is a protective midsole plate that acts as a shield for the bottom of your foot.

How Puncture Resistance Works

The design of a puncture-resistant boot is simple yet highly effective. It focuses on reinforcing the area of the boot most likely to come into contact with sharp ground debris.

The Protective Midsole Plate

The key to this technology is a specialized plate integrated into the boot's sole construction. This plate sits directly above the rubber outsole and below the insole your foot rests on.

When you step on a sharp object, the outsole may be pierced, but the puncture-resistant plate is engineered to stop the object from continuing through to your foot.

Common Hazards Neutralized

These boots are specifically designed to defend against common workplace hazards. This includes protruding nails on a construction site, shards of metal in a scrap yard, or broken glass in a demolition zone.

Key Environments for Use

Puncture-resistant footwear is critical in any environment where the ground is not guaranteed to be clear of sharp debris.

This makes them standard equipment for professionals in construction, demolition, waste management, landscaping, and mining.

Understanding the Materials

The protective plate is the most important component, and it can be made from different materials, each with its own properties.

Traditional Steel Plates

For decades, steel plates have been the standard for puncture resistance. They offer exceptional strength and are highly effective at stopping sharp objects.

Modern Composite Materials

Newer technologies use non-metallic materials like tightly woven fabrics (such as Kevlar) or other composites. These materials are lighter, more flexible, and do not conduct heat, cold, or electricity.

This often results in a more comfortable boot, especially for those who spend long hours on their feet or work in extreme temperatures.

Understanding the Trade-offs

While essential for safety, adding a puncture-resistant plate does introduce considerations you should be aware of.

Flexibility and Comfort

A protective plate, particularly a steel one, can reduce the overall flexibility of the boot's sole. While modern composite plates offer much better flexibility, any reinforced boot will be slightly stiffer than a standard casual shoe.

Weight Considerations

Steel plates add noticeable weight to the footwear. Composite plates are significantly lighter, helping to reduce foot fatigue over a long workday, but they still add more weight than a boot without this feature.

Not a Replacement for Awareness

Puncture-resistant boots are a last line of defense, not an excuse for carelessness. They provide crucial protection but do not make you invincible. Always remain aware of your surroundings and the ground you are walking on.

Making the Right Choice for Your Goal

Selecting the right boot depends entirely on the hazards of your specific environment.

- If your primary focus is working on active construction or demolition sites: A certified puncture-resistant sole is a non-negotiable safety requirement.

- If your primary focus is landscaping or waste management: This feature is highly recommended to protect against unseen debris hidden in grass, soil, or trash.

- If your primary focus is general warehouse work on clean, clear floors: You may be able to prioritize other features like slip resistance or a safety toe, as puncture risk is minimal.

Ultimately, choosing footwear with puncture resistance is a direct investment in your personal safety, allowing you to perform your job with confidence.

Summary Table:

| Feature | Key Benefit | Ideal For |

|---|---|---|

| Steel Plate | Maximum strength & durability | Construction, Demolition |

| Composite Plate | Lightweight, flexible, non-conductive | Landscaping, Extreme Temperatures |

| Protective Midsole | Barrier against sharp object penetration | Waste Management, Mining |

Protect your workforce with the right footwear. As a large-scale manufacturer, 3515 produces a comprehensive range of certified puncture-resistant boots for distributors, brand owners, and bulk clients. Our production capabilities ensure durable, comfortable safety footwear tailored to your specific industry hazards. Contact us today for a quote and discover how we can enhance your safety program.

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- What are the technical advantages of using thin-film Force Sensing Resistors (FSR) in smart training or safety footwear?

- Why is it important to maintain work shoes properly? Protect Your Safety and Investment

- Which is better, steel toe or composite toe boots? Match Your Job's Hazards for Optimal Safety

- What core safety benefits do industrial-grade safety shoes provide for mining? Protect Your Team from High-Intensity Risks

- Why are professional safety shoes necessary for construction site workers? Protect Your Crew from Site Hazards

- How can injury records help in identifying footwear-related dangers? Turn Data into Proactive Safety

- How do the design characteristics of safety shoes or training shoes influence vibration transmission in biodynamic models?

- What are the slip resistance requirements for safety boots? Professional Grip Standards for Poultry Facility Cleaning