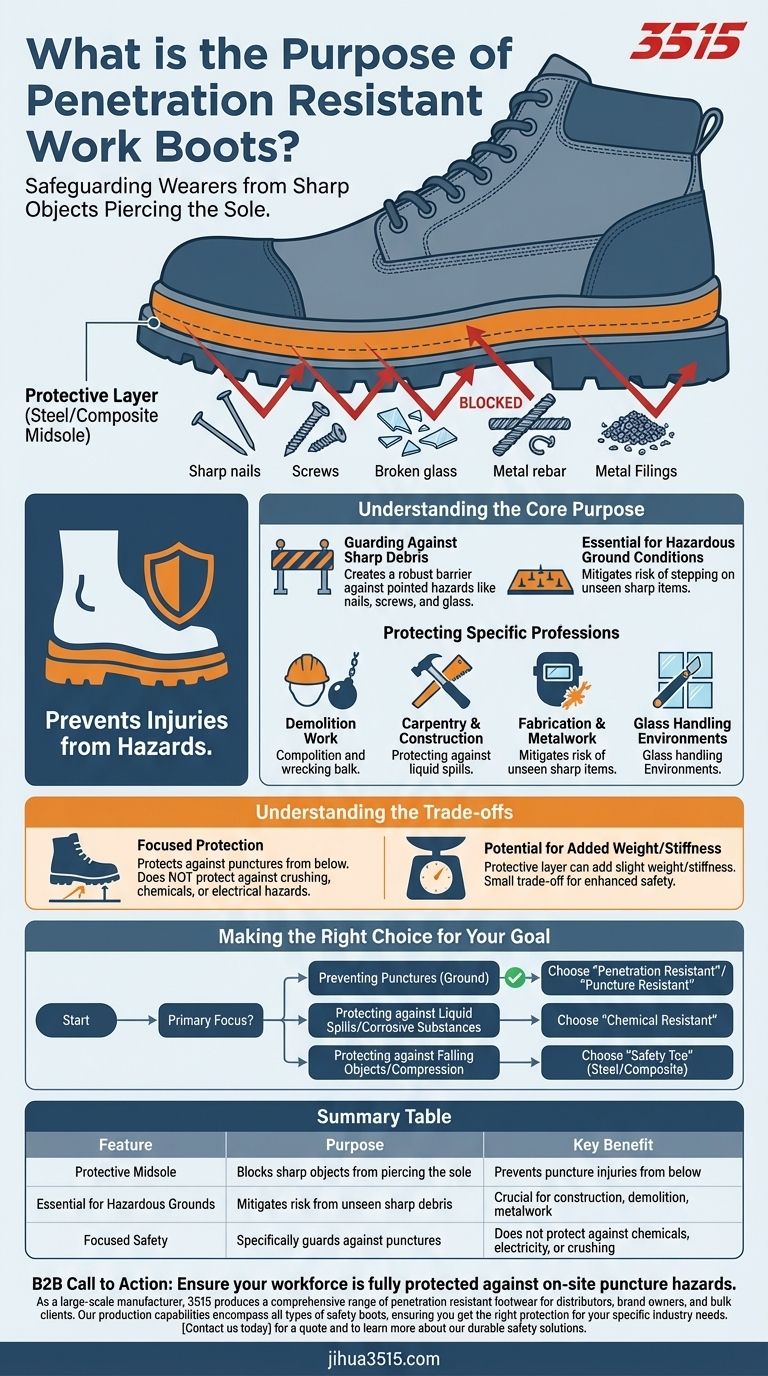

Penetration Resistant work boots are specifically designed to safeguard the wearer's feet from sharp objects that could pierce the sole. Their primary purpose is to prevent injuries from hazards such as nails, screws, glass shards, and sharp metal debris commonly found in various work environments. These boots are crucial for protecting workers in industries where such piercing hazards are prevalent.

Penetration Resistant work boots offer essential protection against punctures from sharp objects on the ground, making them indispensable for workers in construction, demolition, and other hazardous environments where foot injuries from piercing debris are a significant risk.

Understanding the Core Purpose of Penetration Resistance

Penetration resistant work boots integrate a protective layer within the sole to prevent sharp objects from reaching the foot. This specialized construction is vital for worker safety in specific occupational settings.

Guarding Against Sharp Debris

These boots are engineered to create a robust barrier against pointed hazards. They prevent nails, screws, broken glass, and other sharp materials from puncturing the sole.

Essential for Hazardous Ground Conditions

Workplaces often contain unseen dangers on the floor. Penetration resistant soles mitigate the risk of stepping on and injuring the foot with sharp items.

Protecting Specific Professions

Certain roles inherently involve environments littered with piercing hazards. These boots are a key safety component for these professionals.

Demolition Work

In demolition sites, debris like twisted rebar and broken materials frequently lie on the ground. Penetration resistance prevents serious foot injuries.

Carpentry and Construction Sites

Construction zones are notorious for stray nails, screws, and wood splinters. These boots offer critical protection against such common hazards.

Fabrication and Metalwork

Workshops dealing with metal often have sharp offcuts and swarf. Penetration resistant footwear is essential to prevent punctures.

Glass Handling Environments

Environments where glass is cut, processed, or cleaned pose a significant risk from broken shards. These boots provide a necessary defense.

Understanding the Trade-offs

While vital for puncture protection, it's important to recognize that penetration resistance addresses a specific type of hazard. It does not provide universal protection.

Focused Protection

Penetration resistant boots protect against punctures from below. They do not inherently offer protection against other hazards like crushing forces, electrical hazards, or chemical spills.

Not a Universal Solution

Workers facing multiple hazards might require boots with additional features. Chemical resistant boots, for example, are distinct and protect against liquid spills, not punctures.

Potential for Added Weight or Stiffness

The protective layer in the sole, often made of steel or composite materials, can sometimes add a slight increase in boot weight or stiffness. This is a small trade-off for enhanced safety.

Making the Right Choice for Your Goal

Selecting the appropriate work boot depends entirely on the specific hazards of your job.

- If your primary focus is preventing punctures from sharp objects on the ground: Choose boots explicitly labeled as "Penetration Resistant" or "Puncture Resistant."

- If your primary focus is protecting against liquid spills and corrosive substances: You will need "Chemical Resistant" work boots in addition to or instead of penetration resistant ones.

- If your primary focus is protecting against falling objects or compression: Look for boots with a "Safety Toe" (steel, composite, or alloy).

Always match your footwear's safety features directly to the identified risks of your workplace to ensure comprehensive protection.

Summary Table:

| Feature | Purpose | Key Benefit |

|---|---|---|

| Protective Midsole | Blocks sharp objects from piercing the sole | Prevents puncture injuries from below |

| Essential for Hazardous Grounds | Mitigates risk from unseen sharp debris | Crucial for construction, demolition, metalwork |

| Focused Safety | Specifically guards against punctures | Does not protect against chemicals, electricity, or crushing |

Ensure your workforce is fully protected against on-site puncture hazards. As a large-scale manufacturer, 3515 produces a comprehensive range of penetration resistant footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and boots, ensuring you get the right protection for your specific industry needs. Contact us today for a quote and to learn more about our durable safety solutions.

Visual Guide

Related Products

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Wholesale Durable 6-Inch Work Boots | Custom & Private Label Manufacturer

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- Why is leather considered one of the best materials for work boot uppers? Discover Unmatched Durability & Comfort

- How should wildfire boots be maintained for optimal performance? A Guide to Longevity and Safety

- What are some tips for maintaining and cleaning motorcycle boots? Extend the Life of Your Safety Gear

- Why is electrical hazard protection required on some job sites? Essential Safety for High-Risk Environments

- What are the key parts of a work boot's exterior? A Guide to Safety & Durability

- Why do fire boots have a heel? The Critical Safety Feature for Firefighters

- What is a toe rand, and why is it optional? A Guide to Boot Durability

- What are the advantages of soft-toe boots? Superior comfort and flexibility for low-hazard work.