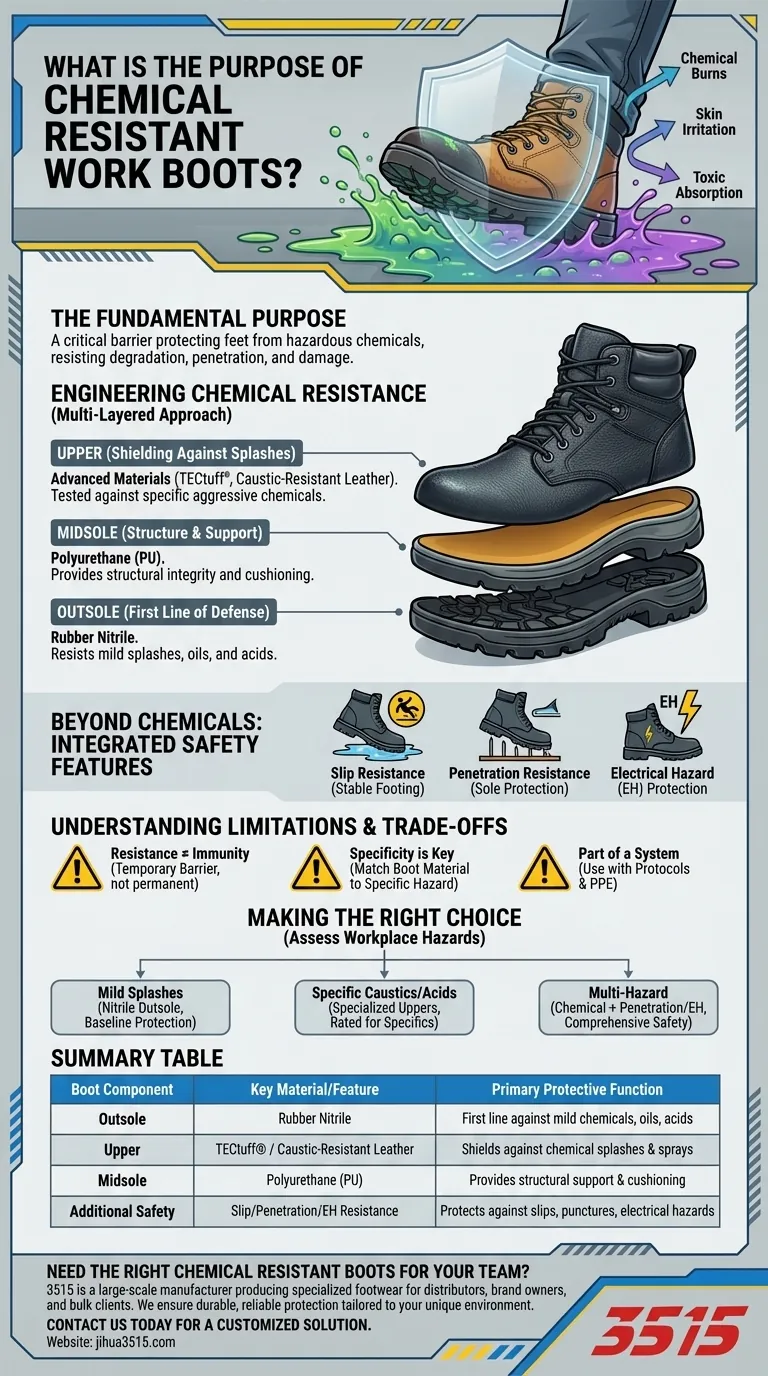

The fundamental purpose of Chemical Resistant work boots is to serve as a critical barrier, protecting a worker's feet from direct contact with hazardous chemicals. These boots are engineered with specialized materials designed to resist degradation, penetration, and damage from specific chemical compounds, thereby preventing chemical burns, skin irritation, and absorption of toxic substances.

While the immediate goal is to block chemical splashes, the deeper purpose is to provide reliable, specified protection within a comprehensive safety system. True safety comes from understanding that not all "chemical resistant" boots are equal—the specific materials used determine their effectiveness against specific threats.

How Chemical Resistance is Engineered

A boot's ability to withstand chemical exposure is not a single feature but the result of a multi-layered material science approach. Each component is selected for a specific protective function.

The Outsole: Your First Line of Defense

The outsole makes direct contact with the ground and is often the first part of the boot exposed to spills. A common material is rubber Nitrile, which provides effective resistance against mild chemical splashes, oils, and acids.

The Upper: Protecting Against Splashes and Sprays

The upper portion of the boot is crucial for shielding against splashes. High-performance boots often use advanced materials like TECtuff® or specially treated, caustic-resistant leather. These materials undergo rigorous testing against specific, aggressive chemicals like Sodium Hydroxide and Sulphuric Acid to validate their protective capabilities.

The Midsole: Providing Structure and Support

While not the primary chemical barrier, the Polyurethane (PU) midsole plays a key role. It provides structural integrity and cushioning, ensuring the boot remains stable and supportive even in harsh industrial environments.

Beyond Chemicals: Integrated Safety Features

Chemical hazards rarely exist in isolation. Therefore, these specialized boots often incorporate other critical safety features to provide comprehensive protection against a range of workplace risks.

Slip Resistance

Chemical spills create dangerously slick surfaces. High-grade slip resistance is a common feature, ensuring stable footing on wet or contaminated floors.

Penetration Resistance

In environments like demolition, construction, or fabrication workshops, the risk of stepping on sharp objects like nails or metal shards is high. Penetration Resistant plates are often built into the boot to protect the sole of the foot.

Electrical Hazard (EH) Protection

For roles where workers may encounter live electrical circuits, Electrical Hazard (EH) rated boots provide a secondary source of protection against electrocution.

Understanding the Limitations and Trade-offs

Recognizing what these boots cannot do is as important as knowing what they can. Objectivity is crucial for safety.

Resistance is Not Immunity

Chemical resistance has limits. The boots are designed to resist damage for a period, giving the worker time to decontaminate. Prolonged exposure to high concentrations of aggressive chemicals will eventually degrade any material.

Specificity is Key

There is no single boot that is resistant to all chemicals. A boot rated for Sulphuric Acid may not be effective against a different solvent. You must match the boot's material specifications to the specific chemical hazards present in your workplace.

A Boot is Only One Part of a System

Chemical resistant boots are a component of Personal Protective Equipment (PPE), not a complete solution. They must be used in conjunction with strict safety protocols, proper chemical handling procedures, and comprehensive hazard awareness training.

Making the Right Choice for Your Environment

Selecting the appropriate boot requires a clear assessment of your primary workplace hazards.

- If your primary focus is protection from occasional, mild splashes: A boot featuring a rubber Nitrile outsole offers a solid baseline of protection.

- If your primary focus is direct work with specific caustics or acids: You must select boots with uppers specifically tested and rated for those chemicals, such as caustic-resistant leather.

- If your primary focus is a multi-hazard environment (e.g., construction or demolition): Choose a boot that combines chemical resistance with penetration resistance and other necessary safety features like a steel toe or EH rating.

Ultimately, choosing the right protective footwear is an exercise in matching the specific engineering of the boot to the specific risks of your job.

Summary Table:

| Boot Component | Key Material/Feature | Primary Protective Function |

|---|---|---|

| Outsole | Rubber Nitrile | First line of defense against mild chemicals, oils, and acids |

| Upper | TECtuff® / Caustic-Resistant Leather | Shields against chemical splashes and sprays |

| Midsole | Polyurethane (PU) | Provides structural support and cushioning |

| Additional Safety | Slip/Penetration/EH Resistance | Protects against slips, punctures, and electrical hazards |

Need the right chemical resistant boots for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of specialized footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and boots, engineered to meet specific chemical resistance and workplace hazard requirements. We ensure durable, reliable protection tailored to your unique environment. Contact us today for a customized solution that safeguards your workforce.

Visual Guide

Related Products

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Premium Grain Leather Safety Boots for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- Why is manufacturer diversity and inclusion important in work boot design? For Superior Fit, Safety & Comfort

- What are the primary protective functions of safety shoes with steel toes in the automotive repair industry?

- What physical protections are provided by the S1 standard and integrated steel toecaps in industrial safety boots? Ensure Ultimate Foot Safety & Hazard Protection

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What is the significance of providing standardized steel-toed safety shoes? Enhance Occupational Health Research Accuracy