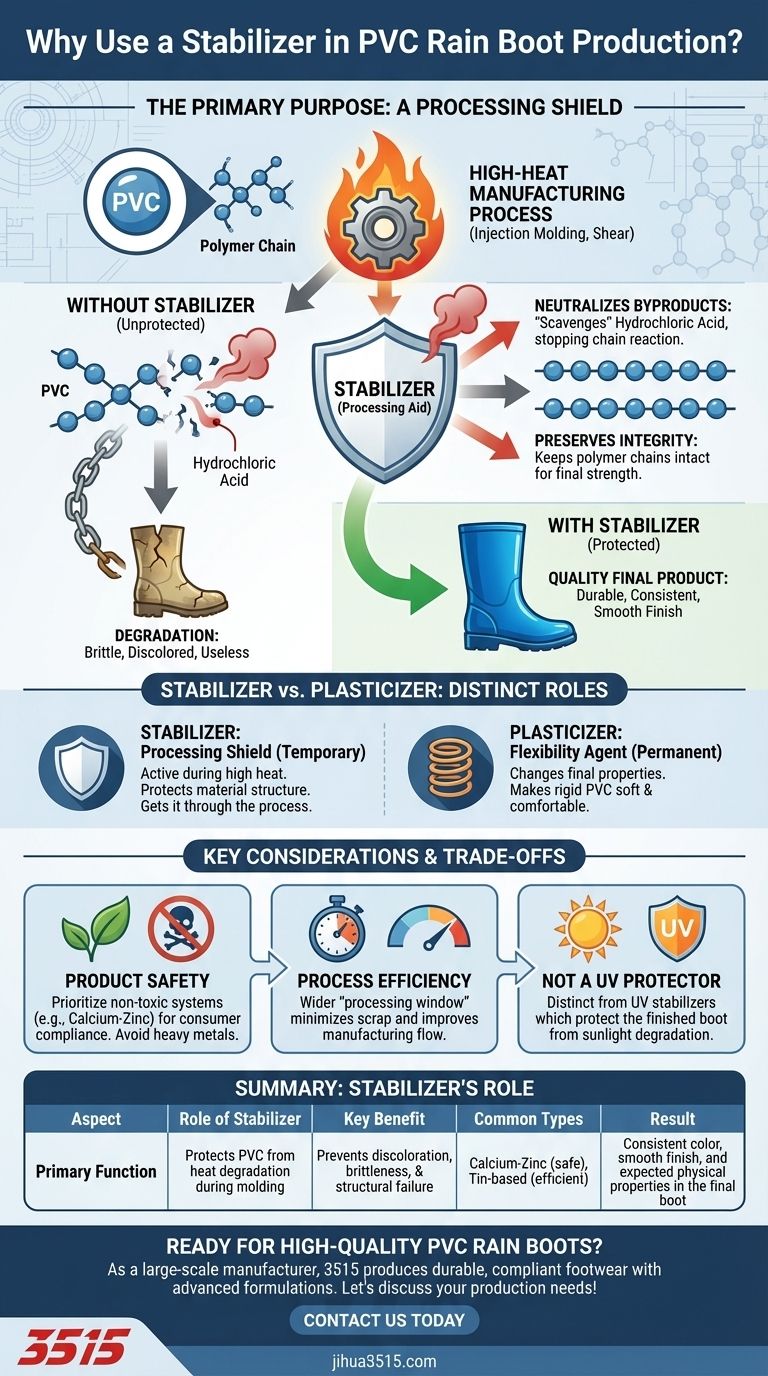

The primary purpose of a stabilizer is to protect the Polyvinyl Chloride (PVC) material from breaking down during the high-heat manufacturing process. It acts as a crucial processing aid that prevents the molecular structure of the PVC from decomposing under the thermal and mechanical stress required to mold it into a rain boot.

In short, the stabilizer is not for the finished boot, but for the PVC during its transformation into a boot. It ensures the raw material survives the manufacturing process intact, resulting in a durable and safe final product.

Why PVC Needs Protection

Raw PVC is inherently unstable when subjected to heat. Without a protective additive, the manufacturing process itself would destroy the very material you are trying to shape.

The Inherent Instability of PVC

PVC's chemical structure is sensitive to high temperatures. When heated above approximately 140°C (284°F), it begins a rapid degradation process.

The Stress of Manufacturing

Creating a rain boot, typically through injection molding, requires melting PVC pellets and forcing them into a mold. This involves significant heat and mechanical shear, conditions that would ruin unprotected PVC.

The Decomposition Chain Reaction

This degradation isn't a simple melting. The heat causes PVC molecules to release hydrochloric acid, which in turn acts as a catalyst, accelerating the decomposition of the surrounding PVC. This chain reaction quickly "burns" the material, rendering it brittle, discolored, and useless.

The Role of the Stabilizer

The stabilizer's job is to interrupt this destructive chain reaction before it can ruin the material, allowing the PVC to be successfully processed.

Neutralizing Destructive Byproducts

Heat stabilizers work by "scavenging" the initial molecules of hydrochloric acid as soon as they are released. By neutralizing this acid, they stop the catalyst that fuels the chain reaction.

Preserving Molecular Integrity

By preventing widespread decomposition, the stabilizer ensures the long polymer chains that give PVC its strength and structure remain intact. This is critical for the final boot's durability.

Ensuring a Quality Final Product

A properly stabilized PVC compound results in a boot with consistent color, a smooth surface finish, and the expected physical properties. An unstable compound would lead to defects, discoloration, and brittleness.

Stabilizers vs. Other Common Additives

It is crucial to distinguish stabilizers from other additives that modify the final product's characteristics, such as plasticizers.

The Stabilizer: A Processing Shield

Think of the stabilizer as a temporary shield that is only active during the high-heat manufacturing phase. Its primary function is to get the material through the process.

The Plasticizer: A Flexibility Agent

A plasticizer, as mentioned in the references, is added to change the properties of the final product. It works its way between the PVC polymer chains, making the rigid material soft and flexible—essential for a comfortable rain boot.

Understanding the Trade-offs

The choice of stabilizer is not just a technical decision; it has significant implications for safety, cost, and regulatory compliance.

Impact on Product Safety

Historically, stabilizers based on heavy metals like lead and cadmium were common. These are now heavily regulated or banned in consumer goods due to their toxicity. Modern, safer alternatives include systems based on tin, or mixed metals like calcium-zinc.

Processing Window and Efficiency

Different stabilizers offer different levels of thermal protection. A more effective stabilizer provides a wider "processing window," giving manufacturers more leeway in temperature and time, which can reduce material scrap and improve efficiency.

Not a UV Protector

The heat stabilizers used for processing are distinct from UV stabilizers. UV stabilizers may be added to the PVC formula separately to protect the finished rain boot from long-term degradation caused by sunlight.

Making the Right Choice for Production

Understanding the role of additives is the foundation of high-quality PVC manufacturing. Your choice should align with your end goal.

- If your primary focus is product safety and compliance: Prioritize a modern, non-toxic stabilizer system like calcium-zinc to meet international standards for consumer goods.

- If your primary focus is process efficiency: Select a high-performance stabilizer that provides a wide processing window, minimizing material degradation and production defects.

- If your primary focus is final product quality: Ensure the stabilizer effectively preserves the PVC's integrity so that other additives, like plasticizers and pigments, can properly determine the boot's final flexibility and color.

Ultimately, the stabilizer makes the entire process possible, ensuring the material you start with is the material you end up with.

Summary Table:

| Aspect | Role of Stabilizer |

|---|---|

| Primary Function | Protects PVC from heat degradation during molding |

| Key Benefit | Prevents discoloration, brittleness, and structural failure |

| Common Types | Calcium-Zinc (safe), Tin-based (efficient) |

| Result | Consistent color, smooth finish, and expected physical properties in the final boot |

Ready to produce high-quality PVC rain boots with optimal material stability? As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our expertise in PVC formulations, including advanced stabilizer systems, ensures your rain boots are durable, compliant, and manufactured efficiently. Let’s discuss your production needs — contact us today for a tailored solution!

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Durable Spiked Camouflage Boots Wholesale & Factory Production

- Comfortable Block Heel Pumps Wholesale & Custom Factory Production

- Wholesale Lightweight Tactical Boots with Dial Closure OEM & Bulk Orders

People Also Ask

- What are the key features of Wellington boots? Ultimate Protection for Wet & Hazardous Work

- Are wellies waterproof and suitable for snow? The definitive guide to insulated winter wellies

- How did rubber Wellington boots become popular? From Aristocratic Fashion to Working-Class Staple

- What are the disadvantages of PVC boots compared to natural rubber? A Guide to Material Trade-offs

- Should Wellington boots be tight around the calf? The Definitive Guide to a Perfect Fit

- What are the steps for cleaning Wellington boots? A Simple Guide to Preserve Your Boots for Years

- What are the overall advantages of Wellington boots for winter? Unbeatable Waterproofing & Winter Protection

- What should be considered when choosing wellington boots regarding clothing? Ensure a Perfect Fit for Your Activity