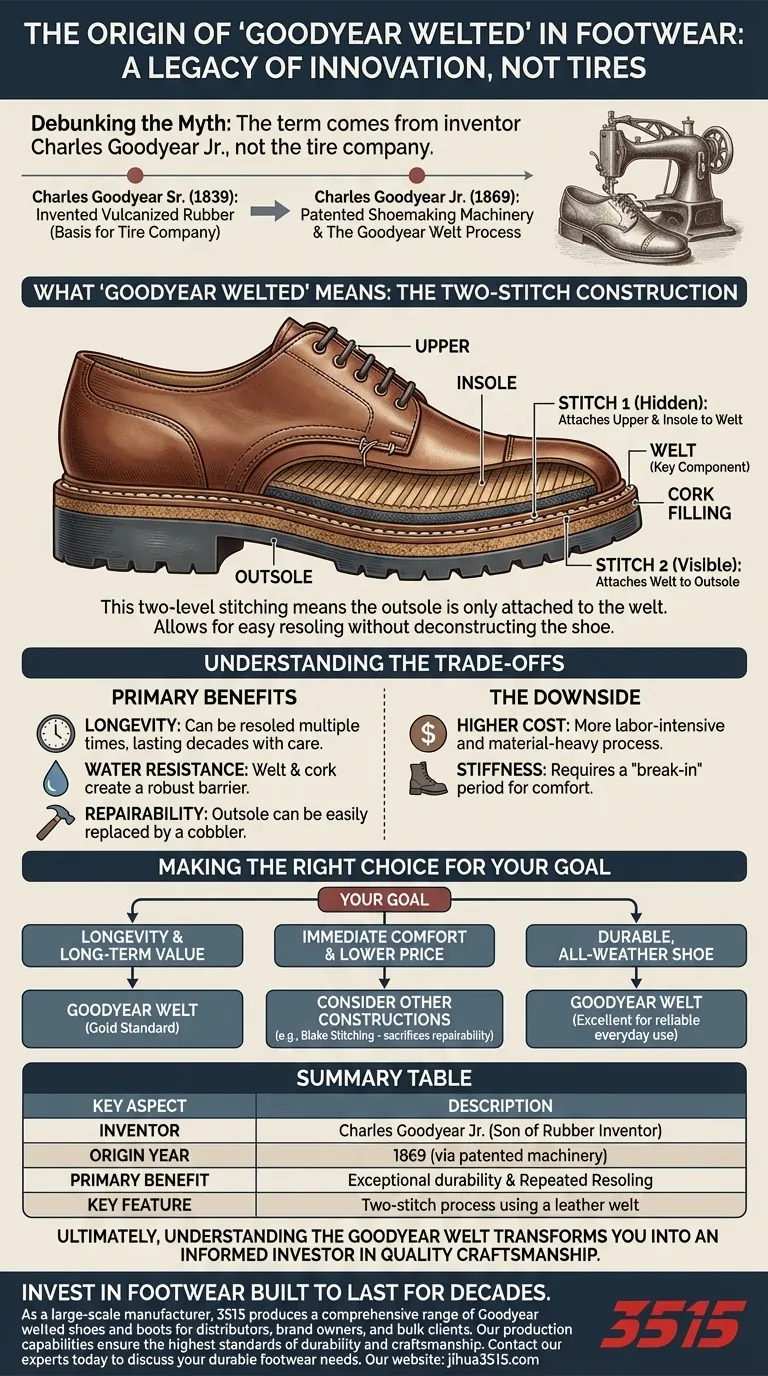

Contrary to popular assumption, the term "Goodyear welted" is not directly related to the famous tire company. It originates from its inventor, Charles Goodyear Jr., who patented the shoemaking machinery in 1869. He was the son of Charles Goodyear, the man who invented the vulcanized rubber used in tires, and the name stems from this legacy of industrial innovation.

While its origin is a piece of history, the term "Goodyear welt" has become a universal benchmark. It signifies a specific method of shoe construction prized for its durability, water resistance, and, most importantly, its ability to be repaired and resoled repeatedly.

The Inventor, Not the Tire Company

The Goodyear name is synonymous with industrial progress, but in the world of footwear, it points to the son's legacy, not the father's.

A Legacy of Innovation

Charles Goodyear Sr. is famous for his 1839 discovery of rubber vulcanization, a process that transformed a sticky, unstable material into the durable, elastic rubber we know today, forming the basis for the Goodyear Tire & Rubber Company.

The 1869 Patent

His son, Charles Goodyear Jr., followed in this innovative spirit. In 1869, he patented machinery that could automate the difficult process of stitching a shoe's sole to its upper. This invention dramatically increased the speed and consistency of manufacturing high-quality, durable footwear.

Why the Name Stuck

The process was so transformative and effective that the inventor's name became inextricably linked to the method itself. "Goodyear welting" became the industry standard for high-end, long-lasting shoe construction.

What "Goodyear Welted" Actually Means for a Shoe

The term describes a specific, multi-step construction process that defines how the shoe is held together. It is a hallmark of quality craftsmanship.

The Key Component: The Welt

The "welt" is a strip of leather that runs along the perimeter of the outsole. It acts as a crucial intermediary, connecting the shoe's upper to the sole without stitching them directly together.

The Two-Stitch Process

A Goodyear welted shoe is identifiable by its two independent stitches, which is the secret to its strength.

- The first stitch, which is hidden, attaches the shoe's upper to the insole and the welt.

- The second stitch, which is often visible on the outside of the shoe, attaches the welt to the outsole.

The Result: A Durable, Resoleable Structure

This two-level stitching means the outsole is only attached to the welt. When the sole wears out, a cobbler can simply cut the second stitch and attach a new outsole without having to deconstruct the entire shoe.

Understanding the Trade-offs

A Goodyear welt is a superior construction method, but it's essential to understand its specific advantages and disadvantages to know if it's right for you.

The Primary Benefit: Longevity

The ability to easily resole the shoe is the single greatest advantage. A well-cared-for Goodyear welted shoe can be resoled multiple times, allowing a single pair to last for decades, not just years.

The Secondary Benefit: Water Resistance

The welt creates a more robust barrier between the insole and the outsole. This, combined with a cork filling that is typically used, makes the shoe significantly more water-resistant than other common constructions.

The Downside: Cost and Stiffness

This method is more labor-intensive and requires more materials, making the shoes more expensive upfront. They are also famously stiff when new and require a "break-in" period for the leather and cork footbed to mold to your foot.

Making the Right Choice for Your Goal

Now that you understand the origin and the mechanics, you can decide if a Goodyear welted shoe aligns with your needs.

- If your primary focus is longevity and long-term value: A Goodyear welt is the gold standard and a wise investment, as the shoe can last for decades with proper care.

- If your primary focus is immediate comfort and a lower price: You might consider other constructions like Blake stitching, but you will sacrifice repairability and water resistance.

- If your primary focus is a durable, all-weather shoe: The robust and water-resistant nature of the Goodyear welt makes it an excellent choice for reliable, everyday footwear.

Ultimately, understanding the Goodyear welt transforms you from a simple shoe buyer into an informed investor in quality craftsmanship.

Summary Table:

| Key Aspect | Description |

|---|---|

| Inventor | Charles Goodyear Jr. (son of the rubber vulcanization inventor) |

| Origin Year | 1869 (via patented machinery) |

| Primary Benefit | Exceptional durability and the ability to be resoled repeatedly |

| Key Feature | A two-stitch process using a leather welt for superior construction |

Invest in footwear built to last for decades. As a large-scale manufacturer, 3515 produces a comprehensive range of Goodyear welted shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities ensure the highest standards of durability and craftsmanship. Contact our experts today to discuss your durable footwear needs.

Visual Guide

Related Products

- Wholesale Durable Leather Work Boots | 8-Inch Goodyear Welt Manufacturer

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

People Also Ask

- What makes work boots durable? The 3 Key Factors for Long-Lasting Footwear

- What are the best practices for storing leather work boots? Preserve Your Investment for Years

- Do heavy duty work boots stretch over time? The Truth About Fit & Break-In

- What are the basic steps to clean leather work boots? A 4-Step Guide to Preserve Your Investment

- Why might it be beneficial to pre-heat the boots before applying wax? Achieve Deeper, Longer-Lasting Protection