At its core, work boot durability is the result of three critical elements working in synergy: the quality of the materials used, the method of construction, and the resilience of the sole. Premium materials like full-grain leather and vulcanized rubber provide the raw strength, while robust construction techniques like stitch-down welts ensure the boot can withstand constant stress without falling apart.

True durability isn't a single feature you can point to. It is the outcome of a manufacturing philosophy that prioritizes high-quality materials and robust construction over cutting costs, ensuring the boot as a whole can endure demanding environments.

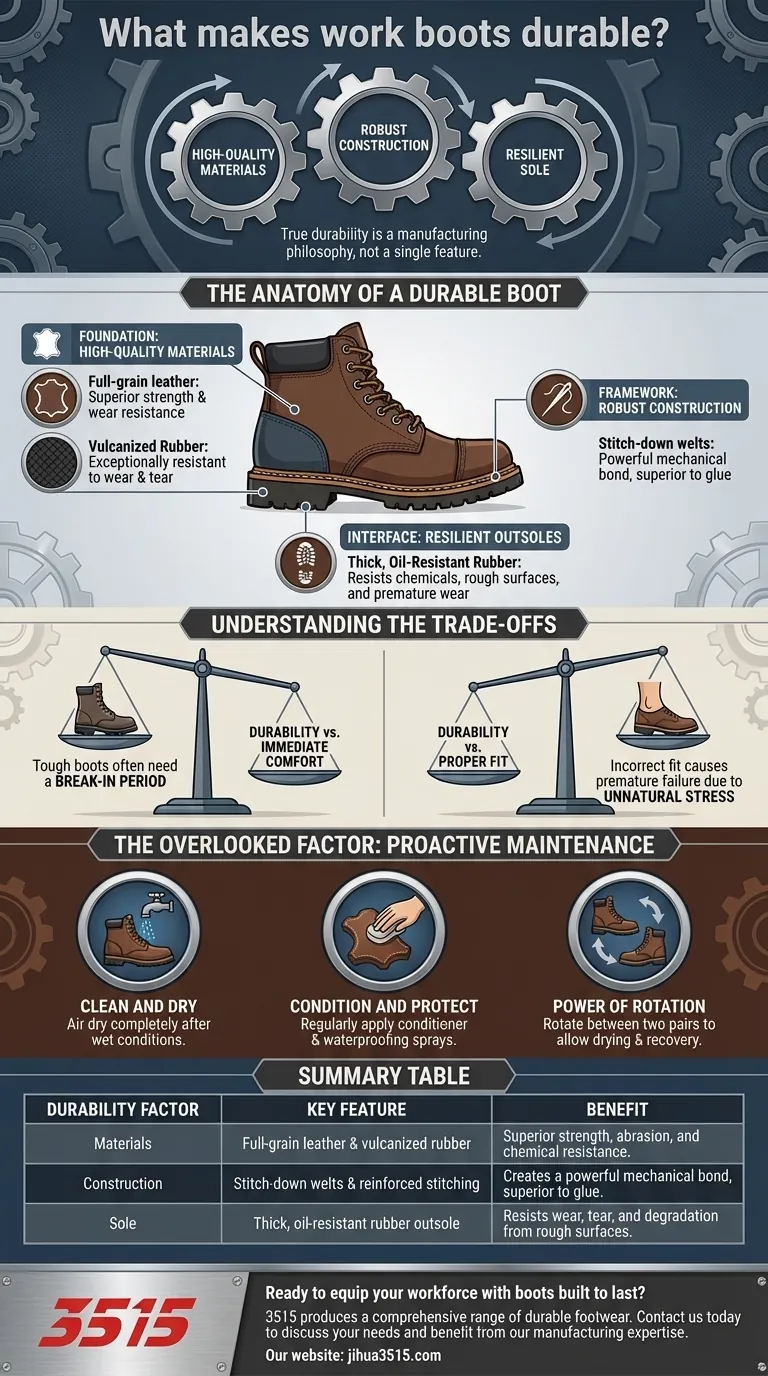

The Anatomy of a Durable Boot

To properly assess a boot's potential lifespan, you must understand its core components. Durability is built from the ground up, starting with the materials that form its structure.

The Foundation: High-Quality Materials

The single most important factor is the material used for the boot's upper. This is the part that faces the most flexing, abrasion, and exposure.

Full-grain leather is widely considered the gold standard for its inherent strength and resistance to wear. It's the highest quality grade of leather, retaining its natural grain and toughness.

For the sole, rubber is the most durable material available. When vulcanized—a process that reinforces its strength—it becomes exceptionally resistant to wear, tear, and abrasion.

Materials like PVC and neoprene are also used but are generally more prone to damage, making them better suited for less demanding conditions.

The Framework: Robust Construction

How a boot is assembled is just as important as the materials it's made from. The method used to attach the upper part of the boot to the sole is a key indicator of quality.

Look for signs of stitch-down welts or reinforced stitching. This is a traditional and highly durable method where the upper is stitched directly to the sole, creating a powerful mechanical bond that is far superior to simple glues or cements.

The Interface: Resilient Outsoles

The outsole is the part of the boot that makes direct contact with the ground. It bears the brunt of every step, scrape, and impact.

A durable boot will feature a thick, oil-resistant sole, typically made of high-grade rubber. This not only protects your foot but also resists degradation from chemicals and rough surfaces, preventing premature cracking and wear.

Understanding the Trade-offs

No boot is perfect for every situation. Choosing the most durable option often involves accepting certain compromises in other areas.

Durability vs. Immediate Comfort

The toughest, most robust boots are often stiff when new. They require a significant break-in period for the leather and sole to conform to your foot.

Softer, more flexible boots might feel more comfortable out of the box, but this often comes at the expense of long-term resilience.

Durability vs. Proper Fit

Durability means nothing if the boot doesn't fit correctly. A boot that is too tight or too loose will cause discomfort and fail prematurely due to unnatural stress on seams and materials.

Always try on boots at the end of the day when your feet are slightly swollen, and wear your typical work socks to ensure an accurate fit.

The Overlooked Factor: Proactive Maintenance

Even the most well-built boot will fail if neglected. Proper care is not an optional step; it is essential to maximizing the lifespan of your investment.

Clean and Dry Regularly

After working in wet or muddy conditions, clean your boots with a damp cloth. Most importantly, allow them to air dry completely before their next use.

Using a boot dryer can prevent odors and ensure the interior materials are fully dry, which prevents breakdown and bacterial growth.

Condition and Protect

Leather is a skin and requires moisture to stay pliable. Regularly applying a quality leather conditioner prevents it from drying out and cracking.

Waterproofing sprays add an extra layer of defense against moisture, further preserving the integrity of the materials.

The Power of Rotation

If possible, owning two pairs of work boots and rotating between them is the single best thing you can do for longevity. This gives each pair a full day to dry and recover its shape, dramatically reducing wear and tear.

Making the Right Choice for Your Goal

Your specific work environment and priorities should guide your final decision.

- If your primary focus is maximum lifespan in harsh conditions: Prioritize boots made with full-grain leather, a stitch-down welt construction, and a thick, vulcanized rubber sole.

- If your primary focus is balancing durability with all-day comfort: Look for robust construction but also pay close attention to the quality of the insole, a moisture-wicking lining, and achieving a perfect fit.

- If your primary focus is protecting your investment: Commit to a strict maintenance routine of cleaning, conditioning, and rotating your boots to drastically extend their service life.

Understanding these core principles empowers you to see past marketing claims and identify the genuine markers of a truly durable work boot.

Summary Table:

| Durability Factor | Key Feature | Benefit |

|---|---|---|

| Materials | Full-grain leather & vulcanized rubber | Superior strength, abrasion, and chemical resistance. |

| Construction | Stitch-down welts & reinforced stitching | Creates a powerful mechanical bond, superior to glue. |

| Sole | Thick, oil-resistant rubber outsole | Resists wear, tear, and degradation from rough surfaces. |

Ready to equip your workforce with boots built to last?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities, focused on high-quality materials and robust construction techniques, ensure your footwear meets the demands of any environment.

Contact us today to discuss your durable work boot needs and benefit from our manufacturing expertise.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Heavy-Duty Waterproof Steel Toe Work Boots OEM Manufacturer

- Wholesale Leather Work Boots with Customizable Wedge Sole for Brands

People Also Ask

- What type of footwear is required in meatpacking and poultry plants due to slippery conditions? Essential Safety Boots for Slippery Floors

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health