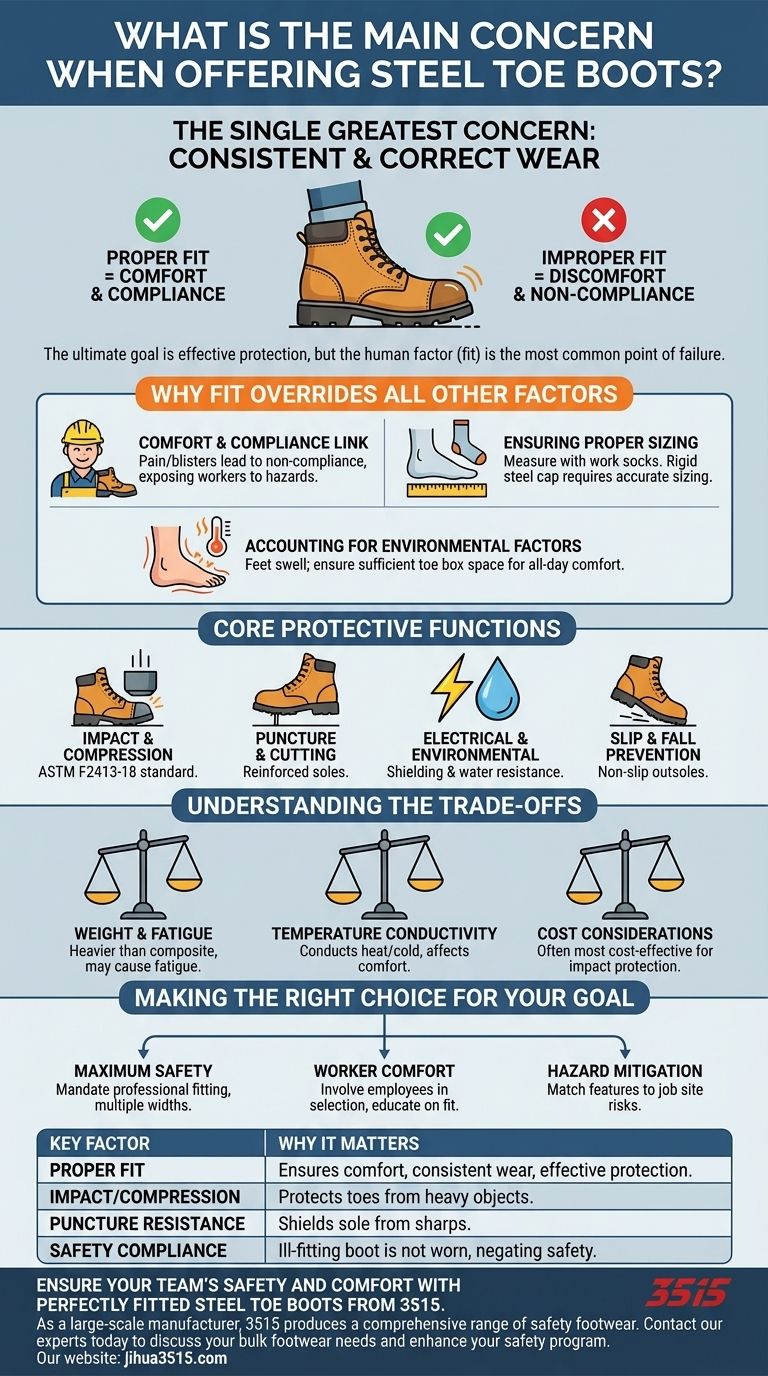

The single greatest concern when offering steel toe boots is ensuring they are worn consistently and correctly, a factor that hinges almost entirely on achieving a proper fit. While the boot's purpose is protection, its safety features become irrelevant if an improper fit leads to discomfort so significant that the employee modifies the boot, wears it improperly, or avoids wearing it altogether.

The ultimate goal is effective protection, but the most common point of failure is not the steel cap itself—it's the human factor. An uncomfortable, ill-fitting boot undermines compliance and turns a critical piece of personal protective equipment (PPE) into a liability.

Why Fit Overrides All Other Factors

A boot can meet every safety standard on paper, but if it doesn't fit the individual's foot, its protective value collapses in practice. This is the central operational challenge.

The Link Between Comfort and Compliance

Workers who experience pain, blisters, or pinching from ill-fitting boots are less likely to wear them for a full shift. This non-compliance exposes them to the very hazards the boots were meant to prevent.

Comfort is not a luxury; it is a core component of a successful safety program.

Ensuring Proper Sizing

Steel toe boots do not have the same flexibility as standard footwear. The steel cap creates a rigid, unforgiving toe box.

It's crucial to measure an employee's feet while they are wearing the thick work socks they will use on the job. Sizing up is often necessary.

Accounting for Environmental Factors

Consider that feet can swell over the course of a long workday, especially in hot environments. A boot that feels snug in the morning may become painfully tight by the afternoon.

A sufficiently large toe box and proper initial sizing can accommodate this, preventing pain and distraction.

Core Protective Functions of a Steel Toe Boot

Understanding what the boot is designed to do clarifies why wearing it correctly is so important. Each feature addresses a specific, high-risk workplace hazard.

Impact and Compression Resistance

The primary function of the steel toe cap is to protect the toes from falling objects and the crushing force of heavy rolling equipment, such as carts or vehicles. This is mandated by ASTM F2413-18 safety standards.

Puncture and Cutting Hazards

Many work boots include reinforced soles to protect the bottom of the foot from sharp objects like nails, screws, and metal shards that could be stepped on.

Electrical and Environmental Shielding

Specialized boots offer resistance to electrical hazards, preventing the wearer from completing an electrical circuit to the ground. Many are also water-resistant to keep feet dry in extreme weather or wet conditions.

Slip and Fall Prevention

The outsole is a critical safety feature. High-quality steel toe boots are equipped with non-slip soles designed to provide superior traction on wet, oily, or otherwise slick surfaces.

Understanding the Trade-offs

While steel toes offer premier protection, it's important to acknowledge their inherent characteristics. These trade-offs can influence comfort and suitability for a given role.

Weight and Fatigue

Steel is inherently heavier than alternative materials like composite or alloy toes. This extra weight can contribute to foot and leg fatigue over a long shift.

Temperature Conductivity

Steel readily conducts temperature. In cold environments, steel toe boots can become very cold, while in extreme heat, they can retain warmth. This can be a significant comfort factor.

Cost Considerations

Generally, steel toe boots are the most traditional and often the most cost-effective option for impact protection when compared to newer composite materials.

Making the Right Choice for Your Goal

Your approach to providing steel toe boots should be guided by your primary objective. A focus on fit is the common thread that ensures any of these goals are met.

- If your primary focus is maximum safety compliance: Mandate professional fitting and provide options for different widths and sizes to accommodate every employee.

- If your primary focus is worker comfort and adoption: Involve employees in the selection process (from a list of approved models) and educate them on how to check for a proper fit.

- If your primary focus is hazard mitigation: Match the boot's specific features (e.g., electrical hazard rating, puncture resistance) to the known risks of the job site.

Ultimately, a proactive focus on proper sizing transforms a safety mandate from a simple requirement into a truly effective protective measure for your team.

Summary Table:

| Key Factor | Why It Matters |

|---|---|

| Proper Fit | Ensures comfort, leading to consistent wear and effective protection. |

| Impact/Compression Resistance | Protects toes from heavy falling or rolling objects (ASTM F2413-18). |

| Puncture Resistance | Shields the foot's sole from sharp objects like nails or metal shards. |

| Safety Compliance | An ill-fitting boot is often not worn, negating all safety features. |

Ensure your team's safety and comfort with perfectly fitted steel toe boots from 3515.

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, ensuring you get the right fit, features, and protection for your workforce.

Contact our experts today to discuss your bulk footwear needs and enhance your safety program.

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

People Also Ask

- What are the advantages of wearing steel-toe boots? Maximum Protection for Heavy-Duty Work

- How does lacing technique affect steel toe boot comfort? Unlock a Perfect, Pain-Free Fit

- When are steel-toe boots required or recommended? Essential Guide to Workplace Foot Safety

- What are the key features of steel toe footwear? Maximum Impact Protection for Demanding Work

- What weatherproofing features are available in steel toe boots? Stay Dry & Safe in Any Condition

- What does OSHA say about steel toe boots? A Guide to Compliant Footwear

- Why choose composite toe boots over steel toe? Lighter, Non-Conductive & Metal Detector Safe

- What are key tips for fitting steel toe boots correctly? Ensure Safety and All-Day Comfort