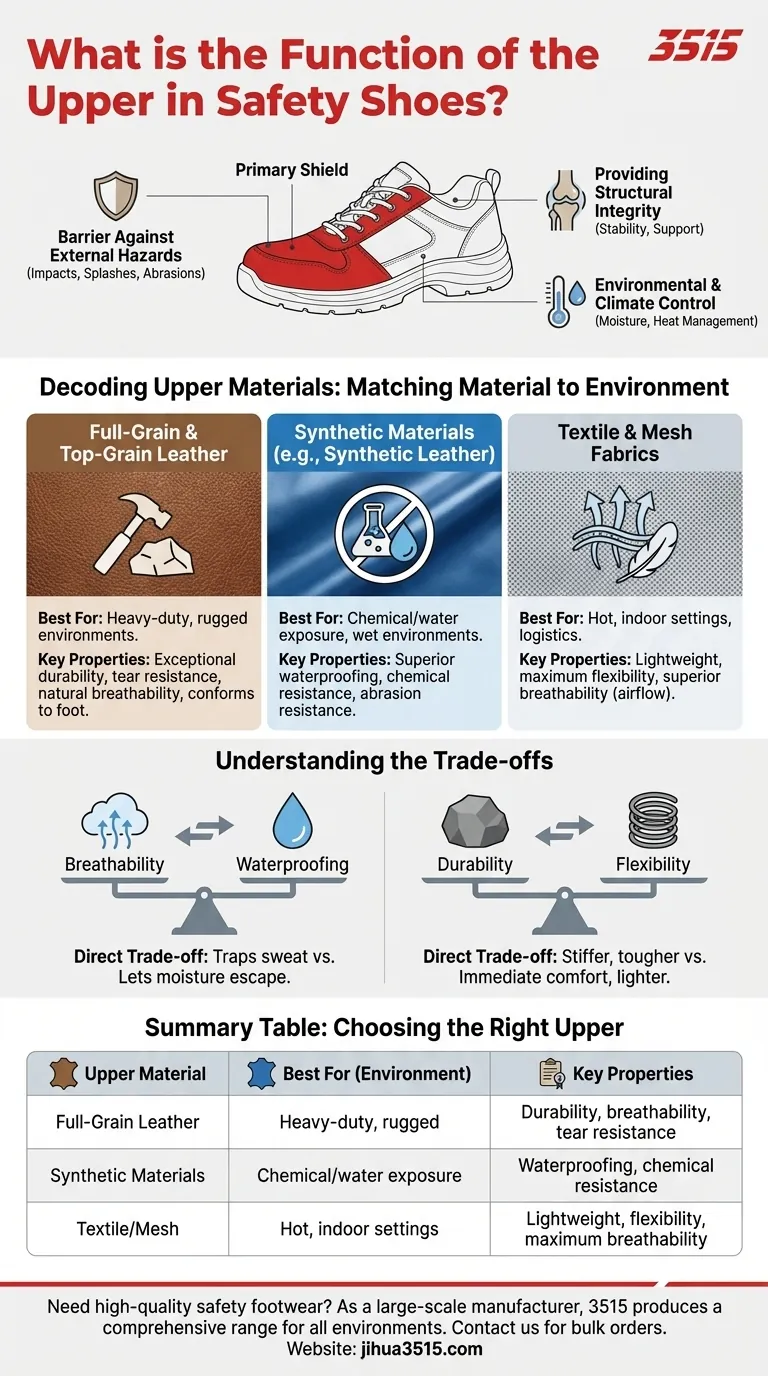

At its core, the upper is the primary shield of a safety shoe. It is the entire part of the shoe that covers the top, sides, and back of your foot, enclosing it securely over the sole. The upper's fundamental function is to protect you from direct workplace hazards like impacts, splashes, and abrasions, while its specific material determines its performance in different environments.

The function of a safety shoe's upper goes far beyond simply holding the boot together. Think of it as the specific environmental interface for your foot—its material and construction directly determine the shoe's resistance to chemicals, water, and abrasion, as well as its breathability and overall durability.

The Upper's Dual Role: Protection and Performance

The upper is not a passive component; it actively contributes to both safety and wearer comfort. It serves as the first line of defense against a wide range of workplace risks.

A Barrier Against External Hazards

The most critical role of the upper is to act as a barrier. It works in tandem with the safety toe cap to protect the foot from falling objects, compression, and impacts.

Furthermore, the material of the upper is chosen to shield the foot from specific environmental dangers such as chemical splashes, hot sparks, or water ingress.

Providing Structural Integrity

The upper provides the shoe's fundamental structure, holding your foot securely in place. This support is crucial for stability on uneven surfaces and helps prevent twists or sprains during strenuous activity.

Environmental and Climate Control

The choice of upper material directly impacts the climate inside your shoe. A well-chosen upper will manage moisture and heat, which is essential for foot health and comfort during long shifts.

Decoding Upper Materials: Matching Material to Environment

The material of the upper is the single most important factor defining its performance characteristics. Each material is engineered for a different set of working conditions.

Full-Grain and Top-Grain Leather

Leather is the traditional choice for heavy-duty work, prized for its exceptional durability and resistance to tearing.

It also offers a high degree of natural breathability and moisture-wicking capabilities, conforming to the foot over time for a comfortable fit. This makes it ideal for general construction and demanding industrial environments.

Synthetic Materials (e.g., Synthetic Leather)

Synthetic materials excel where uniform resistance is required. They are engineered to provide superior protection against specific hazards like chemicals, oils, and liquids.

These materials offer excellent waterproofing and high resistance to abrasion, making them a reliable choice for wet environments, food processing, or chemical handling.

Textile and Mesh Fabrics

Mesh and other textiles are used when flexibility and breathability are the highest priorities. These materials are significantly lighter and more agile than leather or synthetics.

Their primary advantage is superior airflow, which helps keep feet cool and dry in hot or indoor environments like logistics, warehousing, and light manufacturing.

Understanding the Trade-offs

Selecting the right upper is always a matter of balancing competing priorities. No single material is perfect for every situation.

Breathability vs. Waterproofing

There is a direct trade-off between keeping water out and letting moisture (sweat) escape.

Highly waterproof synthetic uppers can trap sweat, leading to discomfort. Highly breathable mesh uppers, conversely, offer minimal protection from rain or splashes.

Durability vs. Flexibility

The toughest, most abrasion-resistant materials like thick leather are often stiffer and require a break-in period.

Lighter, more flexible materials like textiles offer immediate comfort and less weight but will not withstand the same level of abuse as a heavy-duty leather boot.

How to Choose the Right Upper for Your Work

Your choice of safety shoe should be dictated by the specific hazards and conditions of your environment.

- If your primary focus is durability in a rugged, dry environment: Choose a full-grain leather upper for its unmatched toughness and natural breathability.

- If your primary focus is protection from chemicals or water: Opt for a synthetic upper that provides a superior, non-porous barrier against specific liquids.

- If your primary focus is all-day comfort in a hot, indoor setting: A textile or mesh upper will offer the best flexibility and airflow to keep your feet cool.

Understanding the upper empowers you to select safety footwear that works not just for you, but with you in your specific role.

Summary Table:

| Upper Material | Best For | Key Properties |

|---|---|---|

| Full-Grain Leather | Heavy-duty, rugged environments | Durability, breathability, tear resistance |

| Synthetic Materials | Chemical/water exposure | Waterproofing, chemical resistance |

| Textile/Mesh | Hot, indoor settings | Lightweight, flexibility, maximum breathability |

Need high-quality safety footwear tailored to your specific work environment?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety shoes and boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of uppers—from durable leather for construction to chemical-resistant synthetics and breathable textiles for indoor use.

We help you provide the right protection and comfort for your workforce. Contact us today to discuss your safety footwear needs!

Visual Guide

Related Products

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- What is the purpose of front hardeners in safety shoes? Essential Protection for Construction & Welding

- Why is the use of specialized work boots with high comfort levels necessary for welding? Enhance Safety and Endurance

- How do safety shoes with reinforced toe protection and puncture-resistant midsoles serve as a physical barrier?

- Why is stabilization control essential for UHSS safety shoe toe caps? Key Factors for High-Strength Protection

- What are the primary safety functions of safety boots with steel-toe designs? Essential Protection for Industry