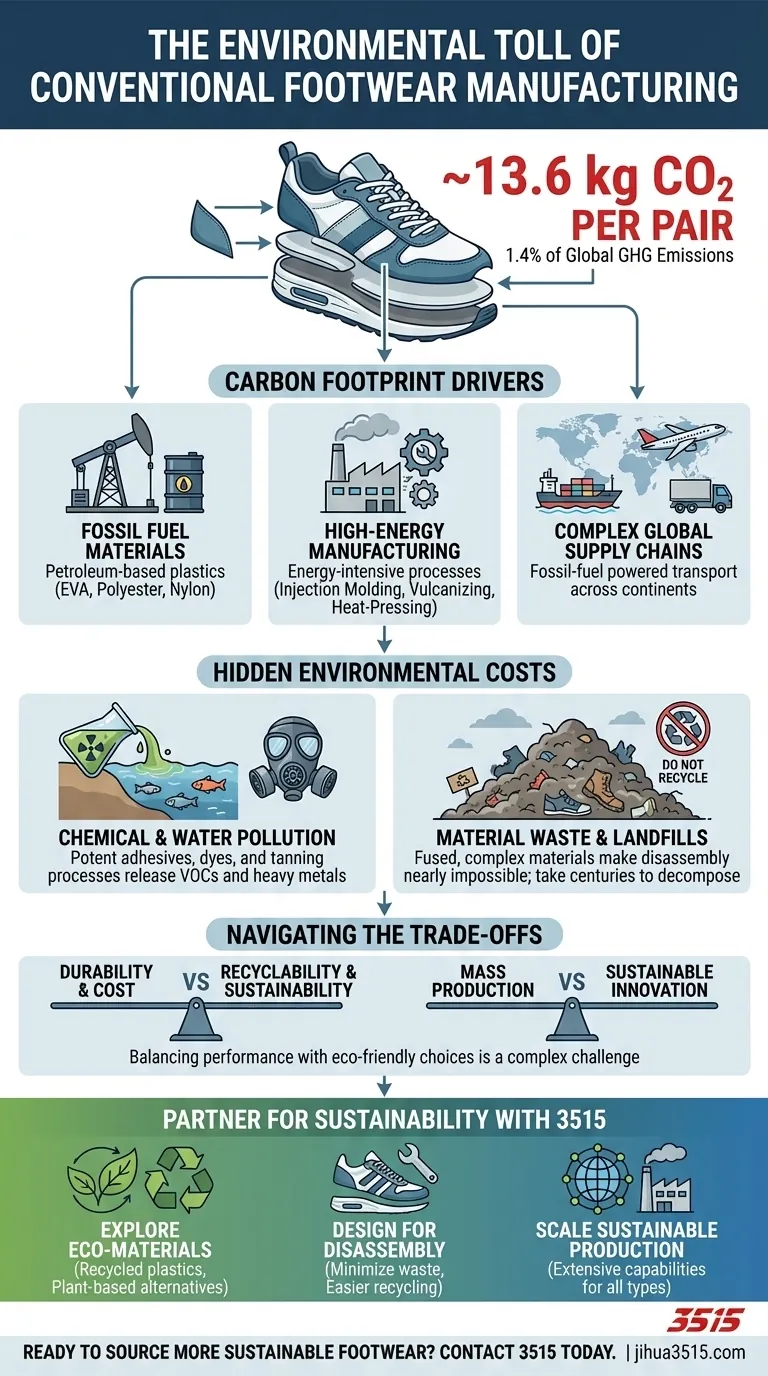

The environmental impact of conventional footwear manufacturing is substantial, driven by a heavy reliance on fossil fuels for both materials and energy. The industry is responsible for an estimated 1.4% of all global greenhouse gas emissions, with the production of a single pair of traditional sneakers generating approximately 13.6 kilograms of carbon dioxide.

The core issue is not a single factor but the entire lifecycle of a conventional shoe—from its petroleum-based materials and energy-intensive assembly to its complex, globally-distributed supply chain and its eventual destination in a landfill.

The Carbon Footprint: Deconstructing the 13.6 kg

The significant carbon dioxide output of a single pair of shoes is a direct result of specific industrial processes and material choices that have been optimized for cost and volume, not sustainability.

The Dominance of Fossil Fuels

Most modern athletic shoes are made from synthetic materials like EVA (ethylene vinyl acetate) foam, polyester, and nylon. These are all plastics derived directly from petroleum.

Extracting and processing these fossil fuels into usable materials is an energy-intensive process that releases large amounts of CO2 before a shoe is even designed.

High-Energy Manufacturing

Factories that produce footwear consume immense amounts of electricity, often sourced from coal or natural gas.

Key manufacturing steps, such as injection molding for soles, heat-pressing components together, and vulcanizing rubber, are particularly energy-demanding, adding significantly to the final carbon tally of each pair.

Complex Global Supply Chains

The journey of a shoe is rarely simple. Raw materials may be sourced from one continent, shipped to another for processing, assembled in a third, and finally distributed globally for sale.

Each leg of this journey, typically powered by fossil-fuel-burning ships, planes, and trucks, adds another layer of emissions to the final product.

Beyond Carbon: The Hidden Environmental Costs

While greenhouse gas emissions are a critical metric, the environmental toll of footwear extends to chemical pollution and landfill waste, creating long-term ecological problems.

Chemical and Water Pollution

Conventional shoe assembly relies on potent adhesives and solvents to bond the numerous parts together. These chemicals can release volatile organic compounds (VOCs) into the atmosphere.

Furthermore, the dyes used to color textiles and the tanning processes for leather often involve heavy metals and toxic chemicals that can contaminate local water sources if not managed properly.

Material Waste and Landfills

The very design of a modern shoe makes it a major contributor to waste. A single sneaker can contain dozens of different materials—plastics, foams, textiles, and rubbers—all fused and glued together.

This complex construction makes disassembly for recycling nearly impossible. As a result, the vast majority of the billions of pairs of shoes produced each year end up in landfills, where they can take centuries to decompose.

Understanding the Trade-offs

Moving towards sustainable footwear is not a simple switch. It involves navigating complex challenges and balancing competing priorities that explain why conventional methods persist.

Durability vs. Recyclability

Materials that are highly durable and perform well under stress, like many synthetic rubbers and plastics, are often the most difficult to recycle.

Conversely, some easily recycled or biodegradable materials may not offer the same level of performance or longevity that consumers expect from their footwear, creating a difficult engineering challenge.

Cost and Scale

The existing global footwear supply chain is built for immense scale and low production costs. This is what makes conventional shoes affordable for the mass market.

Sustainable alternatives, which may use novel materials or require more complex manufacturing processes, often come with a higher price tag, creating a barrier to widespread adoption for both manufacturers and consumers.

Making an Informed Choice

Understanding where the impact comes from empowers you to select footwear that better aligns with your environmental priorities.

- If your primary focus is reducing carbon emissions: Seek out shoes made from recycled plastics or plant-based materials and from brands that are transparent about using renewable energy in their factories.

- If your primary focus is minimizing waste and pollution: Prioritize shoes made from fewer materials (monomaterials) that are designed for easier recycling, and support brands that use natural dyes and water-based adhesives.

Ultimately, awareness of the hidden costs in a simple pair of shoes is the first step toward driving industry-wide change.

Summary Table:

| Key Environmental Impact | Key Contributing Factor |

|---|---|

| 1.4% of Global GHG Emissions | Fossil fuel-based materials & energy-intensive manufacturing |

| ~13.6 kg CO2 per Pair | Petroleum extraction, processing, and complex global supply chains |

| Chemical & Water Pollution | Use of toxic adhesives, dyes, and tanning processes |

| Major Landfill Waste | Complex, fused materials that are nearly impossible to recycle |

Ready to Source More Sustainable Footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. We understand the environmental challenges of conventional production and are equipped to help you navigate them.

We can help you:

- Reduce your carbon footprint by exploring materials like recycled plastics and plant-based alternatives.

- Minimize waste through designs that are easier to disassemble and recycle.

- Scale sustainable production with our extensive manufacturing capabilities for all types of shoes and boots.

Let's build a better product for your customers and the planet.

Contact 3515 today to discuss your sustainable footwear needs.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium KPU Athletic Safety Shoes for Wholesale

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Comfortable Business Casual Shoes Custom Manufacturing

- Wholesale Modern Comfort Shoes with Dial Closure for Private Label & Bulk Orders

People Also Ask

- What were traditional shoe soles made from before rubber? The History of Leather Soles

- Which type of sole is better for hard surfaces? Rubber Soles for Superior Comfort & Durability

- What material is commonly used for the soles of non-slip footwear and why? Unlock the Secrets of Safe Footwear

- What factors determine the slip resistance of rubber-soled shoes? Tread, Compound & Design Explained

- How do rubber soles affect a shoe's appearance? Defining Your Shoe's Style and Formality