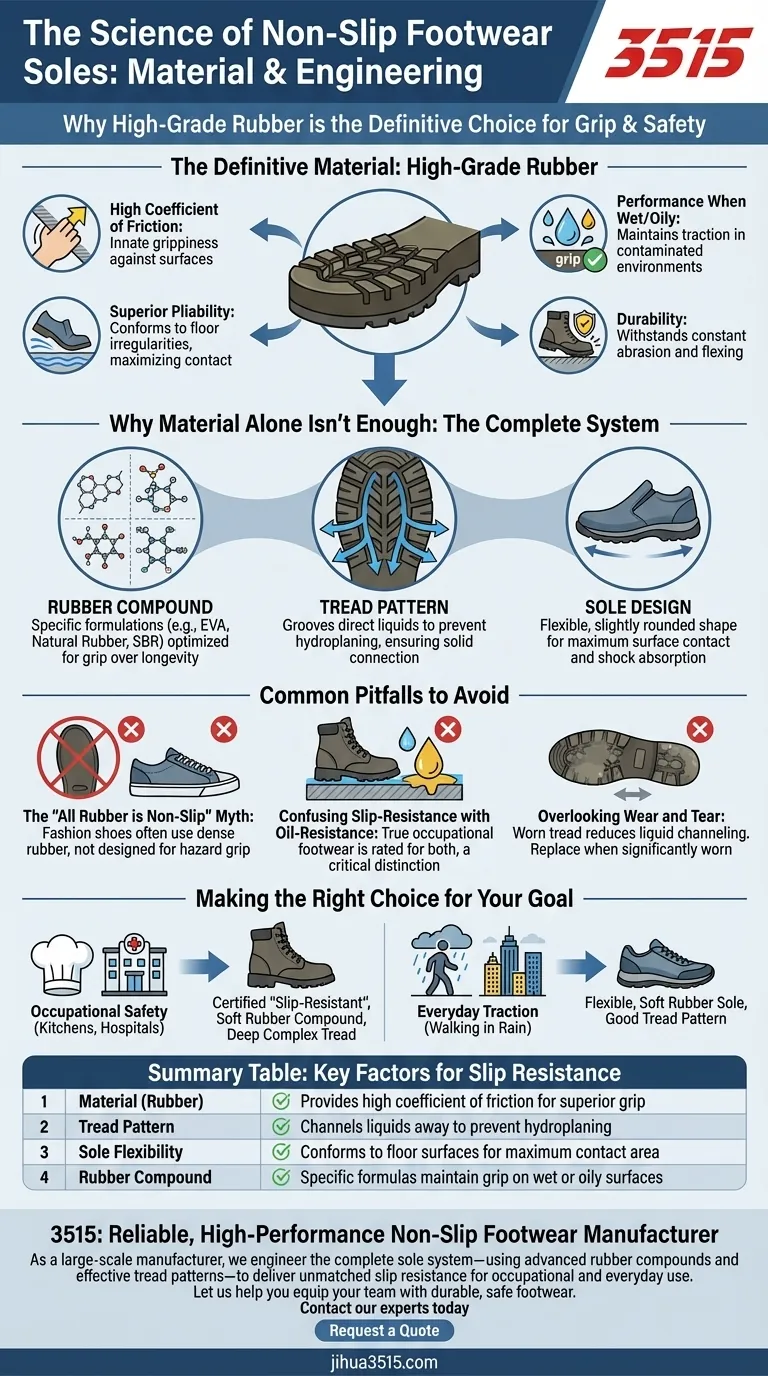

The definitive material for the soles of non-slip footwear is overwhelmingly high-grade rubber. This choice is not arbitrary; it is based on rubber's inherently high coefficient of friction, which provides excellent grip and traction. Specialized rubber compounds are engineered to maintain this grip even on wet, greasy, or oily surfaces.

While rubber is the essential base material, true slip resistance is a function of a complete system: the specific rubber compound, an effective tread pattern designed to channel liquids, and a flexible sole design that maximizes surface contact.

The Core Properties of Non-Slip Rubber

High Coefficient of Friction

Rubber naturally resists sliding against other surfaces. This innate "grippiness" is the primary reason it forms the foundation of all slip-resistant footwear.

Superior Pliability

Effective non-slip soles are typically soft and flexible. This pliability allows the rubber to conform to microscopic irregularities in a floor surface, significantly increasing the total contact area and therefore the available grip.

Performance When Wet

Unlike materials such as leather, specialized rubber compounds are formulated to maintain their traction even when contaminated with water or oil. This property is critical in environments like commercial kitchens or industrial settings.

Durability

While providing flexibility, high-grade rubber is also engineered for durability. It withstands the constant abrasion and flexing of walking far better than less suitable materials, ensuring the sole's integrity and grip over time.

Why the Material Alone Isn't Enough

Simply having a rubber sole does not guarantee a shoe is slip-resistant. The design and engineering of that sole are just as important as the material itself.

The Critical Role of Tread Pattern

The pattern of grooves on the bottom of the sole is a crucial design element. These channels are engineered to direct liquids like water and oil away from the shoe's point of contact with the floor, preventing a hydroplaning effect and allowing the rubber to make a solid connection.

The Importance of Sole Design

A well-designed non-slip outsole, often made of a compound like EVA rubber, is typically lightweight and slightly rounded on the sides. This shape helps maintain maximum surface contact as you walk and shift your weight, while the material's softness absorbs shock.

The Rubber Compound Matters

Not all rubber is created equal. Different types, such as natural rubber or Styrene-Butadiene Rubber (SBR), have distinct properties. Manufacturers of non-slip footwear use specific compounds optimized for grip, often at the expense of other characteristics.

Common Pitfalls to Avoid

The "All Rubber is Non-Slip" Myth

The most common mistake is assuming any shoe with a rubber sole is non-slip. Many fashion or casual sneakers use hard, dense rubber compounds designed for longevity, not for maximum grip on hazardous surfaces.

Confusing Slip-Resistance with Oil-Resistance

A sole can be slip-resistant on water but perform poorly on oily surfaces. True occupational non-slip footwear is typically rated for both water and oil, a critical distinction for professional environments.

Overlooking Wear and Tear

As a non-slip sole wears down, its tread pattern becomes less effective at channeling liquids. The shoe must be replaced once the tread is significantly worn to maintain its safety features.

Making the Right Choice for Your Goal

Understanding the factors beyond the material itself empowers you to select the correct footwear for your specific needs.

- If your primary focus is occupational safety (e.g., kitchens, hospitals): Look for footwear explicitly marketed and certified as "slip-resistant," with a soft rubber compound and a deep, complex tread pattern.

- If your primary focus is everyday traction (e.g., walking in the rain): A shoe with a flexible, relatively soft rubber sole and a good tread will offer superior grip compared to hard leather or plastic soles.

Ultimately, assessing the entire sole system—material, pattern, and design—is the key to identifying truly effective non-slip footwear.

Summary Table:

| Key Factor | Why It Matters for Slip Resistance |

|---|---|

| Material (Rubber) | Provides a high coefficient of friction for superior grip. |

| Tread Pattern | Channels liquids away to prevent hydroplaning. |

| Sole Flexibility | Conforms to floor surfaces for maximum contact area. |

| Rubber Compound | Specific formulas maintain grip on wet or oily surfaces. |

Need reliable, high-performance non-slip footwear for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our expertise lies in engineering the complete sole system—using advanced rubber compounds and effective tread patterns—to deliver unmatched slip resistance for occupational and everyday use.

Let us help you equip your team with durable, safe footwear. Contact our experts today to discuss your specific needs and request a quote.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Custom OEM Training Shoes Wholesale Manufacturer Durable & Breathable

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

People Also Ask

- What makes natural rubber provide excellent traction and grip? Unlocking Superior Performance with Molecular Science

- Why should we wear rubber soled shoes? Unlock Superior Safety and Durability

- What makes rubber sole shoes an economical and practical choice? Unmatched Durability & All-Weather Value

- What are the disadvantages of leather shoe soles? Key Limitations in Traction & Durability

- Which type of sole is better for premium sneakers and why? The Definitive Guide to Rubber Outsoles