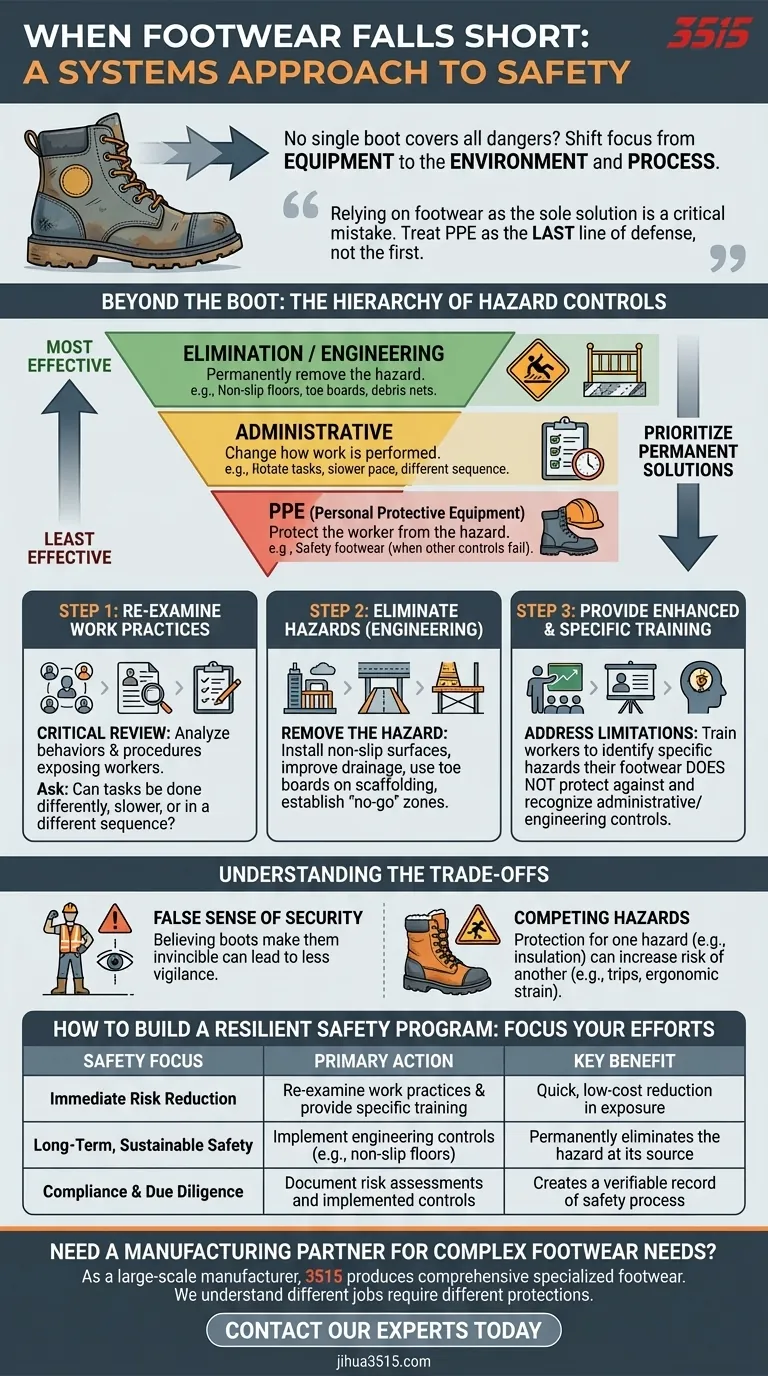

In situations where no single piece of footwear can protect against all potential dangers, the solution is to shift focus from the equipment to the environment and the process. This involves re-examining work practices, engineering hazards out of the workspace, and implementing more specific training protocols.

Relying on footwear as the sole solution to workplace safety is a critical mistake. True safety is achieved when you treat Personal Protective Equipment (PPE) as the last line of defense, not the first, by actively removing the underlying hazards.

Beyond the Boot: A Systems Approach to Safety

The belief that a perfect piece of equipment can solve a safety problem is a common pitfall. A more robust strategy involves a principle known as the Hierarchy of Hazard Controls, which prioritizes more effective and permanent solutions over simply relying on PPE.

When footwear has limitations, it's a clear signal that you must move up this hierarchy to address the root cause of the risk.

Step 1: Re-examine Work Practices

Your first action should be a critical review of how the work is actually performed. This is an administrative control that can immediately reduce risk without any capital investment.

Look for behaviors or procedures that expose workers to the hazards in question. Ask if tasks can be performed differently, at a slower pace, or in a different sequence to minimize exposure.

Step 2: Eliminate Hazards Through Environmental Changes

This is the most effective and permanent solution. Instead of protecting the worker from the hazard, you remove the hazard from the worker. This is an engineering control.

If a floor is slippery, the primary solution isn't just a better slip-resistant shoe. The most effective fix is to make the floor less slippery by installing non-slip surfaces, improving drainage, or using different cleaning agents.

If there is a risk of falling objects, the solution isn't just a steel-toed boot. It's installing toe boards on scaffolding, using debris nets, and establishing clear "no-go" zones under overhead work.

Step 3: Provide Enhanced and Specific Training

When you know the footwear has specific limitations, your training must address them directly. This goes far beyond simply telling employees to wear their boots.

Effective training ensures workers can identify the specific hazards their footwear does not protect against. It empowers them to recognize high-risk situations and understand the administrative and engineering controls that are in place to keep them safe.

Understanding the Trade-offs

Relying exclusively on PPE, especially when you know it's imperfect, introduces significant risks that are often overlooked.

The False Sense of Security

PPE can create a false sense of security, leading workers to take risks they otherwise wouldn't. If a worker believes their boots make them invincible, they may be less vigilant about the actual environmental hazards.

The Problem of Competing Hazards

Often, a feature that protects against one hazard can increase the risk of another. A heavily insulated boot for electrical protection might be clumsy and increase the risk of trips, while a puncture-proof sole might reduce flexibility and lead to ergonomic strain.

Accepting that no single boot can solve all problems forces you to build a more comprehensive and resilient safety system.

How to Build a More Resilient Safety Program

Use this framework to decide where to focus your efforts based on your primary objective.

- If your primary focus is immediate risk reduction: Start by re-evaluating work practices and providing targeted training on the specific hazards not covered by footwear.

- If your primary focus is long-term, sustainable safety: Prioritize engineering controls like improving floor surfaces or installing machine guards to permanently eliminate the hazard.

- If your primary focus is compliance and due diligence: Document your risk assessment, the limitations of available PPE, and the specific controls you implemented to mitigate the remaining risk.

Ultimately, a safe workplace is one where safety is engineered into the environment, not just worn by the employee.

Summary Table:

| Safety Focus | Primary Action | Key Benefit |

|---|---|---|

| Immediate Risk Reduction | Re-examine work practices & provide specific training | Quick, low-cost reduction in exposure |

| Long-Term, Sustainable Safety | Implement engineering controls (e.g., non-slip floors, machine guards) | Permanently eliminates the hazard at its source |

| Compliance & Due Diligence | Document risk assessments and all implemented controls | Creates a verifiable record of your safety process |

Need a manufacturing partner that understands the complexities of safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of specialized footwear for distributors, brand owners, and bulk clients. We understand that different jobs require different protections, and our production capabilities encompass all types of safety shoes and boots designed for specific hazards. Let us help you provide the right equipment as part of your holistic safety strategy.

Contact our experts today to discuss your specific safety footwear needs and explore our extensive product catalog.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Can heavy duty work boots be worn daily outside of work? Discover Durable, All-Day Comfort

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management