In short, oil-resistant safety boots should be used in any environment where exposure to oil, petroleum-based solvents, and other slick industrial fluids is a daily reality. This includes workplaces with heavy machinery, automotive shops, manufacturing plants, oil fields, and areas where chemical or hazardous material spills are a risk.

The core purpose of an oil-resistant boot is not just to keep your feet dry, but to prevent the boot's sole from degrading. When standard boot materials are exposed to oil, they can soften, swell, and lose their grip, creating a significant and often unseen slip hazard.

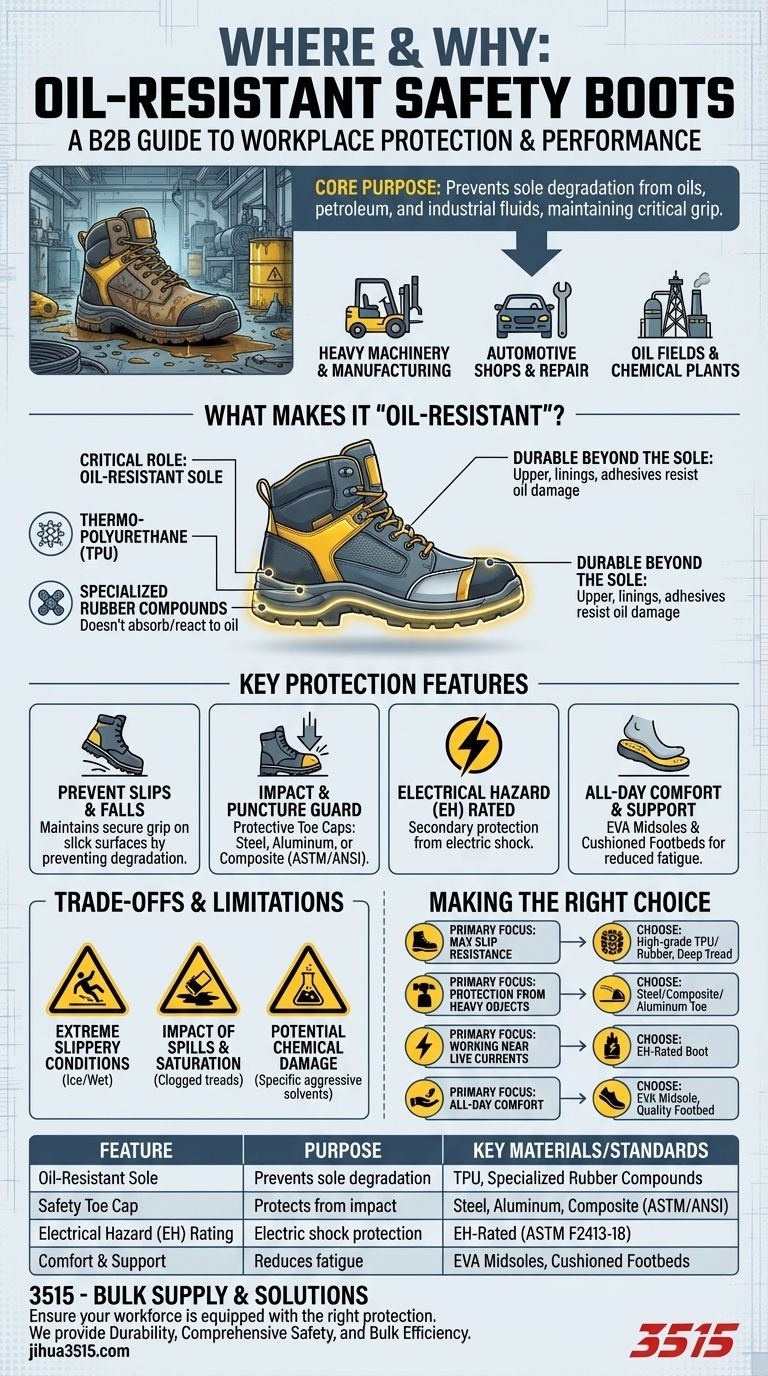

What Makes a Boot "Oil-Resistant"?

The term "oil-resistant" refers to the specific materials used in the boot's construction, primarily the outsole. These materials are engineered to maintain their structural integrity and performance when they come into contact with oils and solvents.

The Critical Role of the Sole

The outsole is the boot's first line of defense. Specific materials are chosen because they do not absorb or react to oil.

Common high-performance sole materials include thermo-polyurethane (TPU), which offers excellent resistance and durability, and specialized rubber compounds. These materials ensure the sole's tread pattern remains effective and the material itself doesn't break down, preserving traction.

Durability Beyond the Sole

True oil-resistant boots are designed holistically. The upper materials, linings, and even the adhesives and stitching are chosen to resist damage from oil exposure. This ensures the entire boot remains a durable piece of personal protective equipment (PPE).

Key Protection Features for Oily Environments

While oil resistance is the headline feature, these boots incorporate a suite of safety technologies designed for the specific hazards of industrial settings.

Preventing Slips and Falls

The primary benefit is maintaining a secure grip on surfaces contaminated with slick fluids. By preventing the sole from degrading, the boot’s traction is preserved, drastically reducing the risk of slips and falls, which are among the most common workplace accidents.

Guarding Against Impact and Puncture

Most oil-resistant boots are also safety boots, featuring protective toe caps. These can be made of steel, aluminum, or lighter-weight composite materials to shield the foot from falling objects and compression from heavy machinery.

Shielding from Electrical Hazards

Many of these boots also offer protection from electrical hazards (EH-rated). This feature is critical for electricians, maintenance crews, and anyone working near live circuits, as it provides a secondary source of protection from electric shock.

Ensuring All-Day Comfort and Support

Worker fatigue is a safety issue. These boots often include supportive midsoles, often made from ethylene-vinyl acetate (EVA), to provide shock absorption and cushioning. A comfortable footbed reduces fatigue for workers who are on their feet all day.

Understanding the Trade-offs and Limitations

Even the best oil-resistant boots are not infallible. Understanding their limitations is key to using them safely and effectively.

Not All "Slippery" is the Same

While highly effective against oil, the boots may still slip in extremely slippery conditions, such as on smooth, wet surfaces or ice. The "oil-resistant" feature is specific to preventing material degradation from hydrocarbons.

The Impact of Spills and Saturation

The non-slip effectiveness can be compromised by large spills or leaks. If the boot's tread becomes completely clogged with a thick substance, its ability to grip the floor surface will be reduced until it is cleaned.

Potential for Chemical Damage

While resistant to oil, certain aggressive solvents or chemicals can still cause permanent damage to the non-slip surface of the sole. Always verify the boot's chemical resistance against the specific substances present in your workplace.

Making the Right Choice for Your Workplace

Selecting the correct boot depends entirely on the specific hazards of your job.

- If your primary focus is maximum slip resistance in oily settings: Prioritize a boot with a high-grade TPU or rubber outsole with a deep, well-defined tread pattern.

- If your primary focus is protection from heavy objects: Ensure the boot has a certified steel, composite, or aluminum toe cap that meets your industry's safety standards.

- If your primary focus is working near live electrical currents: You must select a boot that is explicitly EH-rated for electrical hazard protection.

- If your primary focus is all-day comfort on hard floors: Look for boots with a cushioned EVA midsole and a quality footbed to reduce fatigue and provide shock absorption.

Choosing the right safety boot is a critical decision that directly impacts your well-being at work.

Summary Table:

| Feature | Purpose | Key Materials/Standards |

|---|---|---|

| Oil-Resistant Sole | Prevents sole degradation and maintains grip on oily surfaces. | TPU, Specialized Rubber Compounds |

| Safety Toe Cap | Protects feet from impact and compression from heavy objects. | Steel, Aluminum, Composite (ASTM/ANSI) |

| Electrical Hazard (EH) Rating | Provides a secondary layer of protection against electric shock. | EH-Rated (ASTM F2413-18) |

| Comfort & Support | Reduces fatigue for workers on their feet all day. | EVA Midsoles, Cushioned Footbeds |

Ensure your workforce is equipped with the right protection.

As a large-scale manufacturer, 3515 produces a comprehensive range of oil-resistant safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes, designed to meet the specific hazards of your industry.

We provide:

- Durability & Performance: Boots engineered with high-grade materials like TPU and specialized rubber to maintain integrity in oily conditions.

- Comprehensive Safety Features: Options including steel/composite toes and EH ratings to protect against multiple workplace hazards.

- Bulk Supply Efficiency: Reliable, high-volume manufacturing to meet your distribution or corporate needs.

Let's discuss the perfect safety footwear solution for your business. Contact our team today for expert guidance and competitive pricing.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

People Also Ask

- What are the primary functions of professional protective consumables? Crucial Construction Safety Gear Explained

- Why is the provision of professional Safety Shoes essential? Shield Your Workforce from High-Risk Industrial Hazards

- Why is outsole traction critical for safety shoes in urban low light? Secure Grip for Unseen Hazards

- What are examples of protective footwear required in different workplaces? Ensure OSHA Compliance & Worker Safety

- How do professional-grade safety shoes contribute to the functionality of industrial load-bearing exoskeletons?

- What are the two types of electrical protection offered by safety boots? Anti-Static vs. EH Explained

- What is the primary function of high-friction safety shoes in commercial fishing? Essential Slip-Resistance Guide

- How do professional safety shoes contribute to operational efficiency? Boost Logistics Productivity and Safety