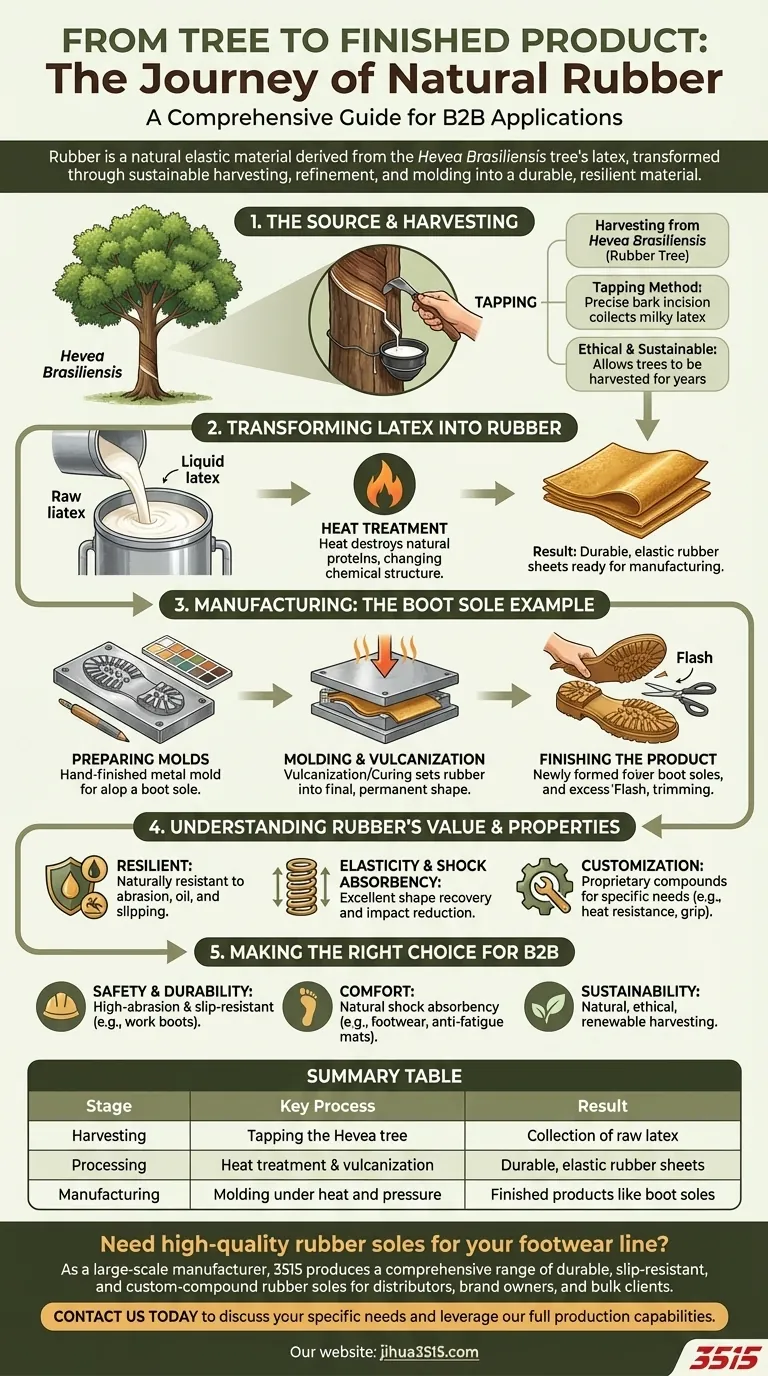

At its core, rubber is a natural elastic material derived from the milky white sap, known as latex, of the Hevea Brasiliensis tree. The production process begins with a harvesting method called tapping, where the tree's bark is carefully cut to collect this latex. The raw sap is then processed, often with heat, to create the durable, flexible, and shock-absorbent material used in countless applications.

Rubber's journey from a tree's sap to a finished product is a transformation from a liquid natural polymer into a highly resilient solid. This is achieved through a sustainable harvesting process followed by refinement and molding to leverage its unique properties of elasticity and durability.

From Tree to Raw Material: The Tapping Process

The Source: Hevea Brasiliensis

The entire process begins with a specific species of tree, the Hevea Brasiliensis, commonly known as the rubber tree. This tree is the primary source for the world's natural rubber.

The Tapping Method

To harvest the rubber, a process called tapping is used. This involves making a precise incision in the tree's bark and allowing the milky white latex to flow out and be collected.

The method is conceptually similar to tapping a maple tree for its syrup.

An Ethical and Sustainable Harvest

Tapping is performed carefully to ensure it does not harm the tree. This ethical approach allows a single tree to be tapped for many years, supporting the long-term viability of rubber plantations and promoting local biodiversity.

Transforming Latex into Usable Rubber

Initial Processing

Once collected, the raw latex undergoes processing to become stable and usable. A key step often involves heat treatment.

This heat destroys certain natural proteins within the latex, fundamentally changing its chemical structure and enhancing its durability.

The Resulting Material

This initial processing transforms the liquid latex into solid sheets of bouncy, golden rubber. This raw material is now ready for manufacturing.

Core Properties of Natural Rubber

The final material is valued for its exceptional physical properties, including:

- High tensile strength and tear resistance

- Excellent elasticity (the ability to return to its original shape)

- Superior shock absorbency

Manufacturing a Finished Product: The Boot Sole Example

Preparing the Molds

Before the rubber is shaped, a mold must be prepared. These molds are often hand-finished and inspected to meet exact design specifications. Color can also be added at this stage.

Molding the Rubber

Raw rubber is placed into the prepared mold. The mold is then closed and heated under pressure.

This process, known as vulcanization or curing, sets the rubber into its final, permanent shape.

Finishing the Product

After heating, the newly formed part is removed from the mold. Any excess rubber, called "flash," is carefully trimmed away to create the clean, finished product, such as a boot outsole.

Understanding the Value of Rubber

A Uniquely Resilient Material

Rubber is one of the most common materials for applications like shoe soles because it is naturally resistant to abrasion, oil, and slipping.

Versatility and Customization

Many manufacturers create proprietary rubber compounds by adding other ingredients. This allows them to enhance specific characteristics, such as increasing heat resistance or improving grip for specialized safety boots.

Making the Right Choice for Your Needs

By understanding the journey and properties of rubber, you can better evaluate the products you use.

- If your primary focus is safety and durability: Look for products specifying high-abrasion or slip-resistant rubber, which is common in high-quality work boots and industrial equipment.

- If your primary focus is comfort: The natural shock absorbency of rubber makes it an excellent choice for footwear or components designed to reduce physical impact.

- If your primary focus is sustainability: Prioritize products that specify the use of natural rubber, supporting an ethical and renewable harvesting process.

Ultimately, recognizing how this remarkable material travels from a tree to a finished good empowers you to appreciate its value and performance.

Summary Table:

| Stage | Key Process | Result |

|---|---|---|

| Harvesting | Tapping the Hevea tree | Collection of raw latex |

| Processing | Heat treatment & vulcanization | Durable, elastic rubber sheets |

| Manufacturing | Molding under heat and pressure | Finished products like boot soles |

Need high-quality rubber soles for your footwear line?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, slip-resistant, and custom-compound rubber soles for distributors, brand owners, and bulk clients. Our expertise ensures your products meet the highest standards of safety, comfort, and performance.

Contact us today to discuss your specific needs and leverage our full production capabilities.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

People Also Ask

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals

- Why does the material performance of professional slip-resistant shoes offer superior safety? Hardware vs. Behavior

- Why is it mandatory to wear safety shoes with steel toe protection during metal loading? Prevent Crushing Injuries

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now