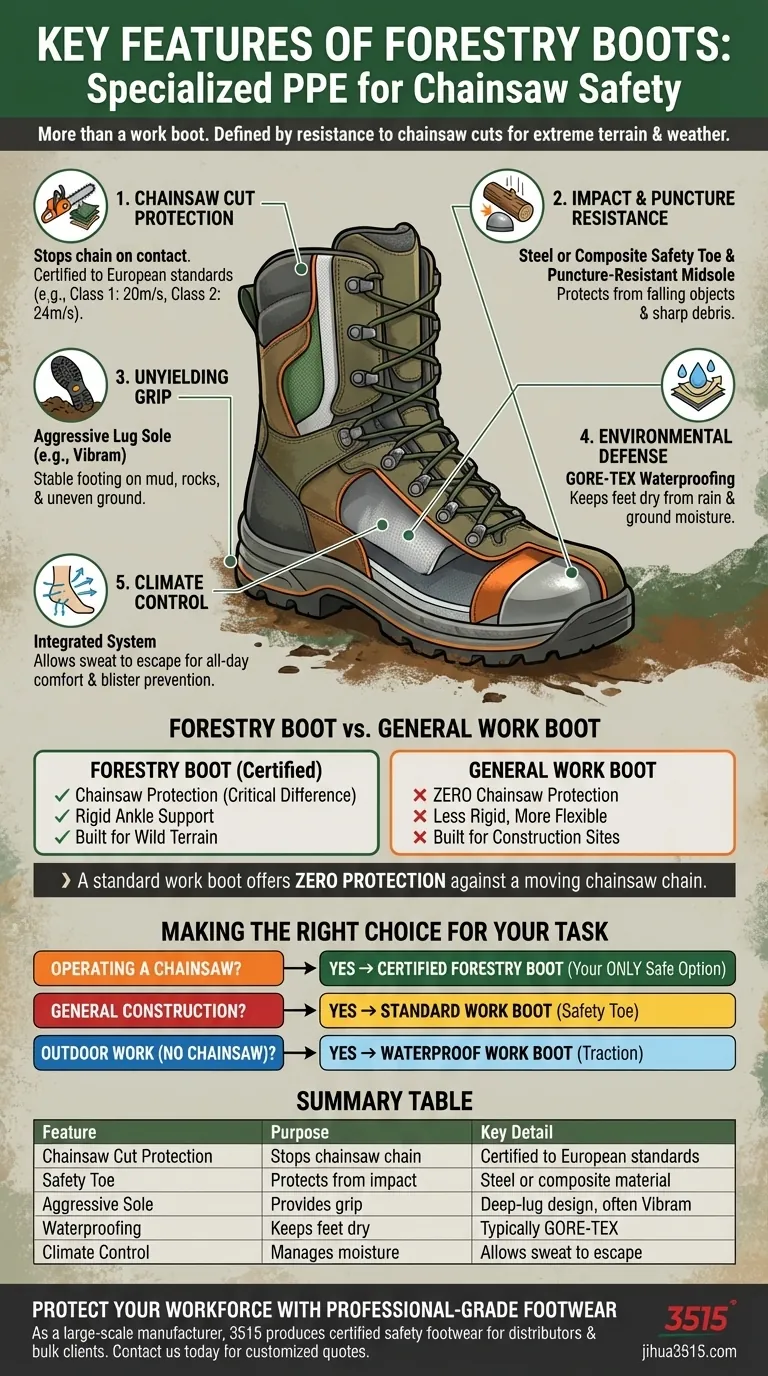

At their core, forestry boots are a highly specialized category of personal protective equipment (PPE) defined by their resistance to chainsaw cuts. Key features include certified cut protection, steel or composite safety toes, aggressive Vibram soles for extreme terrain, GORE-TEX waterproofing, and integrated climate control systems for all-day comfort and safety.

The critical distinction is that a standard work boot protects you from the environment, while a true forestry boot is specifically engineered to protect you from the unique and severe hazards of operating a chainsaw.

Deconstructing the Core Features

To understand why forestry boots are essential for arborists and loggers, we must examine how each component addresses a specific, high-stakes risk found in the field.

Chainsaw Cut Protection: The Defining Feature

The single most important feature is certified cut protection. This is not simply thick leather; it involves layers of specialized fabric designed to clog the sprocket of a chainsaw on contact, stopping the chain.

These boots are rated according to European standards, such as Class 1 (protecting against chain speeds of 20 m/s) and Class 2 (24 m/s), which directly correspond to the power of the equipment being used.

Impact and Puncture Resistance

Like other heavy-duty work boots, forestry boots incorporate steel or composite safety toe caps. This protects the wearer from the impact of falling logs, tools, and other heavy objects.

They also feature puncture-resistant midsoles to guard against sharp sticks, rocks, or debris on the forest floor.

Unyielding Grip: The Role of the Sole

Forestry work occurs on unpredictable and often treacherous ground. To counter this, these boots feature deep, aggressive lug soles, often made by Vibram, a brand renowned for its durable, high-traction rubber compounds.

This design ensures stable footing on mud, wet leaves, rocks, and uneven terrain, preventing slips and falls that could be catastrophic when operating machinery.

Environmental Defense: Waterproofing and Climate Control

Keeping feet dry is critical for both comfort and safety over a long workday. A GORE-TEX membrane provides reliable waterproofing to keep rain and ground moisture out.

Simultaneously, a Climate Control System allows moisture and sweat from inside the boot to escape, keeping the foot dry and preventing the blisters and discomfort that can lead to distraction and accidents.

Forestry Boots vs. General Work Boots

While a heavy-duty work boot offers significant protection, it is crucial to understand why it is not a substitute for a certified forestry boot in a logging environment.

The Critical Difference in Protection

A standard work boot, even a steel-toed one, offers zero protection against a moving chainsaw chain. The leather and even the steel toe can be cut through instantly.

Only boots with the layered, cut-resistant fabric and the appropriate class rating are designed to mitigate this specific risk.

Ankle Support and Rigidity

Both boot types are high-cut to provide ankle support and protect against abrasions. However, the construction of a forestry boot is often far more rigid due to the added layers of protective material.

This rigidity is a necessary trade-off for safety, providing a stable platform and guarding against twists on uneven ground, but it makes them less flexible than a typical construction boot.

Built for Different Hazards

General work boots are designed for hazards like falling objects on a construction site, electrical risks, or slippery factory floors.

Forestry boots are engineered for a wilder, more dynamic environment where the primary threats are a powerful cutting tool and treacherous, natural terrain.

Making the Right Choice for Your Task

Selecting the correct footwear is a non-negotiable safety decision. Your choice must be dictated by the specific tasks you will be performing.

- If your primary focus is operating a chainsaw or working in active logging: A certified forestry boot with the appropriate cut-protection class is your only safe and acceptable option.

- If your primary focus is general construction or factory work: A standard heavy-duty work boot with a safety toe, non-slip sole, and any other required features (e.g., electrical hazard rating) is sufficient.

- If your primary focus is outdoor work without chainsaw risk: A high-quality waterproof work boot with excellent traction and ankle support is appropriate, but it must not be used for chainsaw operation.

Ultimately, choosing the right boot is not just about comfort; it is a critical decision that directly impacts your personal safety on the job.

Summary Table:

| Feature | Purpose | Key Detail |

|---|---|---|

| Chainsaw Cut Protection | Stops chainsaw chain on contact | Certified to European standards (e.g., Class 1, Class 2) |

| Safety Toe | Protects from impact of falling objects | Steel or composite material |

| Aggressive Sole | Provides grip on treacherous terrain | Deep-lug design, often by Vibram |

| Waterproofing | Keeps feet dry in wet conditions | Typically features a GORE-TEX membrane |

| Climate Control | Manages moisture for all-day comfort | Allows sweat to escape, preventing blisters |

Protect Your Workforce with Professional-Grade Forestry Boots

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of specialized boots, including forestry boots engineered with the highest standards of cut resistance, durability, and comfort.

We ensure your team has the essential PPE they need to work safely and efficiently in the most demanding environments. Contact us today to discuss your specific requirements and receive a customized quote.

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium KPU Injection Athletic Style Safety Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What are the key parts of a work boot's interior? The 3 Core Components for All-Day Comfort & Support

- What historical influences contributed to the development of engineer boots? From Cavalry to the Industrial Revolution

- What is the Goodyear Welt construction method? Discover Unmatched Durability & Repairability

- What features are important for plumbers in work boots? The Ultimate Guide to Safety & Performance

- Why is proper care and maintenance important for leather work boots? Extend Lifespan & Protect Your Investment

- What protection do leather work boots need? A Complete Guide to Material Care and Worker Safety

- What should be considered when sizing and fitting engineer boots? Master the Laceless Fit for Maximum Comfort

- How does cleaning your work boots help in their maintenance? Extend Lifespan & Boost Safety