At their core, the difference between work boots and western boots is one of fundamental purpose. Work boots are engineered as personal protective equipment (PPE) for hazardous environments, prioritizing certified safety above all else. Western boots are a specialized tool for horseback riding that have also become a powerful symbol of cultural identity and style.

The choice between a work boot and a western boot is not a matter of style preference; it's a decision based on environment and risk. One is designed to protect you from industrial hazards, while the other is designed for the specific ergonomics of being in a saddle.

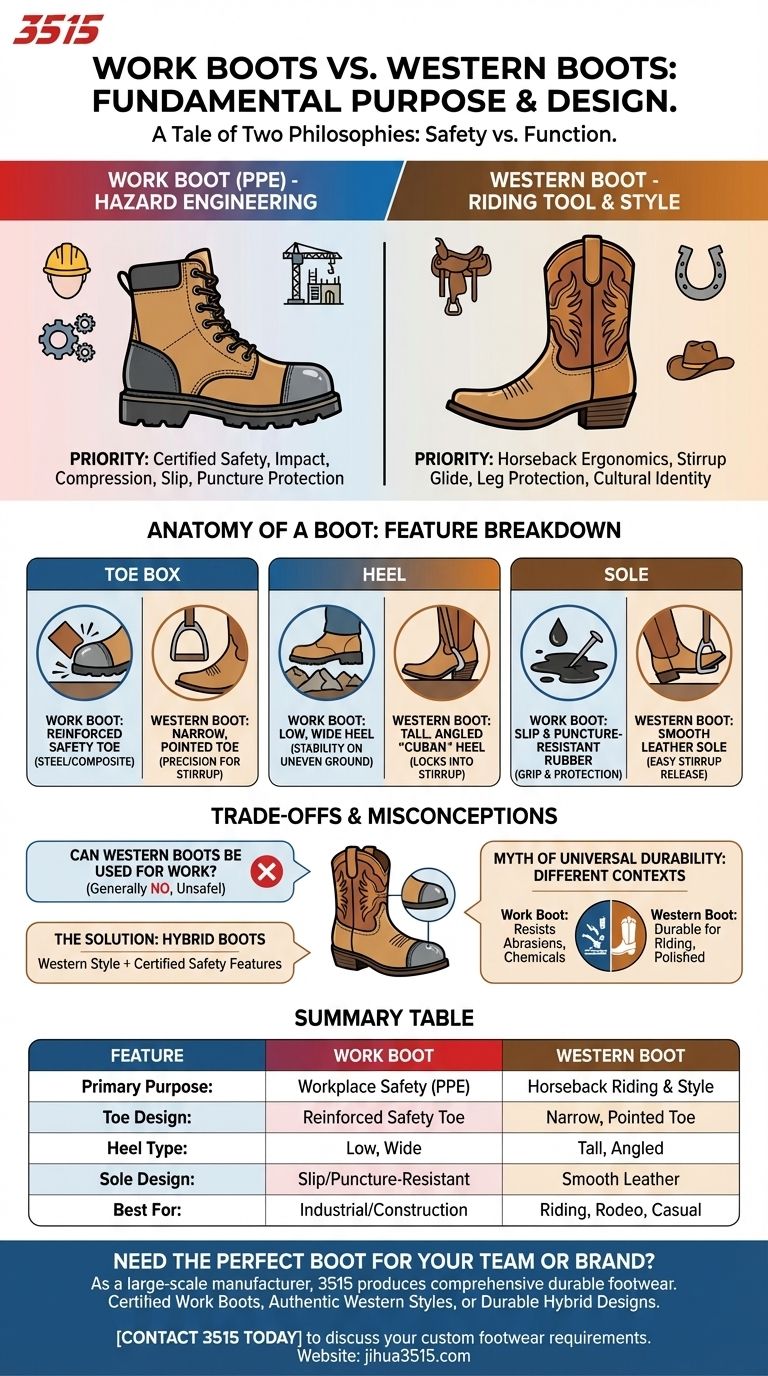

A Tale of Two Philosophies: Safety vs. Function

To truly understand the differences, you must first look at the design philosophy behind each boot. They solve two completely different problems.

The Work Boot: Engineered for Hazard

Work boots are built from the ground up with a single goal: mitigating workplace risk. Their design is dictated by safety standards and the practical needs of industrial job sites.

Every feature, from the materials to the sole, is a functional choice. Aesthetics are a distant secondary concern to ensuring the wearer is protected from impact, compression, punctures, and slips.

The Western Boot: Designed for the Saddle

The traditional western, or "cowboy," boot is a masterclass in functional design for a very specific task: horseback riding. Its iconic look is not accidental; it's the direct result of a rider's needs.

The pointed toe helps guide the foot into the stirrup, the tall shaft protects the leg from chafing against the saddle, and the high, angled heel prevents the foot from slipping through the stirrup, which can be extremely dangerous. Over time, this functional design has evolved into a distinct aesthetic style.

Anatomy of a Boot: A Feature-by-Feature Breakdown

The differing philosophies are most obvious when you compare the boots component by component.

The Toe Box: Protection vs. Precision

A work boot almost always features a reinforced safety toe, typically made of steel, composite materials, or alloy. This is designed to protect the foot from crushing and impact injuries.

A western boot has a narrow, often pointed toe. This shape is not for protection but to make it easier for a rider to quickly find the stirrup with their foot.

The Heel: Stability vs. Security

Work boots have a low, wide heel with a broad base. This design maximizes surface contact with the ground, providing stability when walking on uneven or unpredictable surfaces.

Western boots feature a taller, angled heel, often called a "Cuban heel." Its primary function is to lock into the stirrup, providing a secure footing for the rider.

The Sole: Grip vs. Glide

The sole of a work boot is its foundation for safety. It is typically made of thick, heavy-duty rubber with deep lugs to provide maximum slip resistance on surfaces like oil, water, and mud. Many are also puncture-resistant.

A traditional western boot has a much smoother, often leather sole. This intentional design allows the foot to slide easily in and out of the stirrup, preventing a rider from being dragged if they fall.

Understanding the Trade-offs and Misconceptions

Confusing the purpose of these two boots can lead to poor performance and significant safety risks.

Can Western Boots Be Used for Work?

Generally, no. A traditional western boot is unsafe for an industrial worksite. It lacks a safety toe, has poor slip resistance, and offers no protection from punctures through the sole.

However, the market has responded with "hybrid" boots. These boots blend western styling with certified work boot features like steel toes and slip-resistant rubber outsoles. They are an excellent option if you require both style and protection.

The Myth of Universal Durability

Both boots are durable, but for different contexts. A western boot's polished leather is durable for daily wear and riding but will be quickly damaged by the abrasive conditions of a construction site.

A work boot's heavy-duty leather and rubber are designed to withstand cuts, scrapes, and chemical exposures that would destroy a traditional western boot.

A Note on Fit: Men's vs. Women's Designs

Regardless of type, proper fit is paramount. It's important to recognize that men's and women's boots are constructed differently. Women's boots are not just smaller versions; they are built on a different last to accommodate anatomical differences, such as a narrower heel and a higher arch.

Making the Right Choice for Your Needs

Choosing the right boot is about honestly assessing your primary activity and environment.

- If your primary focus is certified workplace safety: Choose a dedicated work boot that meets the specific safety standards (e.g., ASTM) required for your job.

- If your primary focus is horseback riding or Western style: A traditional western boot is the authentic tool designed specifically for this function and aesthetic.

- If you need both Western style and on-the-job protection: Seek out a modern hybrid boot that explicitly combines a western look with certified safety features.

Ultimately, understanding the design philosophy behind each boot ensures you get the right protection and performance for your environment.

Summary Table:

| Feature | Work Boot | Western Boot |

|---|---|---|

| Primary Purpose | Workplace Safety (PPE) | Horseback Riding & Style |

| Toe Design | Reinforced Safety Toe (Steel/Composite) | Narrow, Pointed Toe |

| Heel Type | Low, Wide Heel for Stability | Tall, Angled 'Cuban' Heel for Stirrup Security |

| Sole Design | Slip & Puncture-Resistant Rubber | Smooth Leather for Easy Stirrup Release |

| Best For | Industrial & Construction Sites | Riding, Rodeo, & Casual Wear |

Need the Perfect Boot for Your Team or Brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Whether you require certified safety work boots, authentic western styles, or durable hybrid designs, our production capabilities encompass all types of shoes and boots to meet your exact specifications and volume needs.

Contact 3515 today to discuss your custom footwear requirements and discover how we can deliver quality, reliability, and value directly to your business.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Durable Leather Work Boots for Wholesale & Custom OEM Manufacturing

- Durable Leather Work Boots for Wholesale & Custom Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- Why is attention to detail important in the design of western boots? It's the Key to Authenticity & Quality

- What are the popular shaft heights for cowboy boots? Find Your Perfect Fit for Work or Style

- Can insulated boots cause feet to sweat? How to ensure dry warmth with the right materials.

- What is a metatarsal guard in Wellington work boots? Essential Protection for High-Risk Jobs

- What are the benefits of nylon and synthetic fibers in firefighter boots? Boost Endurance & Foot Safety

- What are the key features of Rigmaster boots? Unmatched Safety for Harsh Industrial Work

- Why are toe protection safety boots important in construction work? Essential for Impact & Puncture Defense

- What are the long-term benefits of choosing PVC work boots? Durable, Cost-Effective Footwear