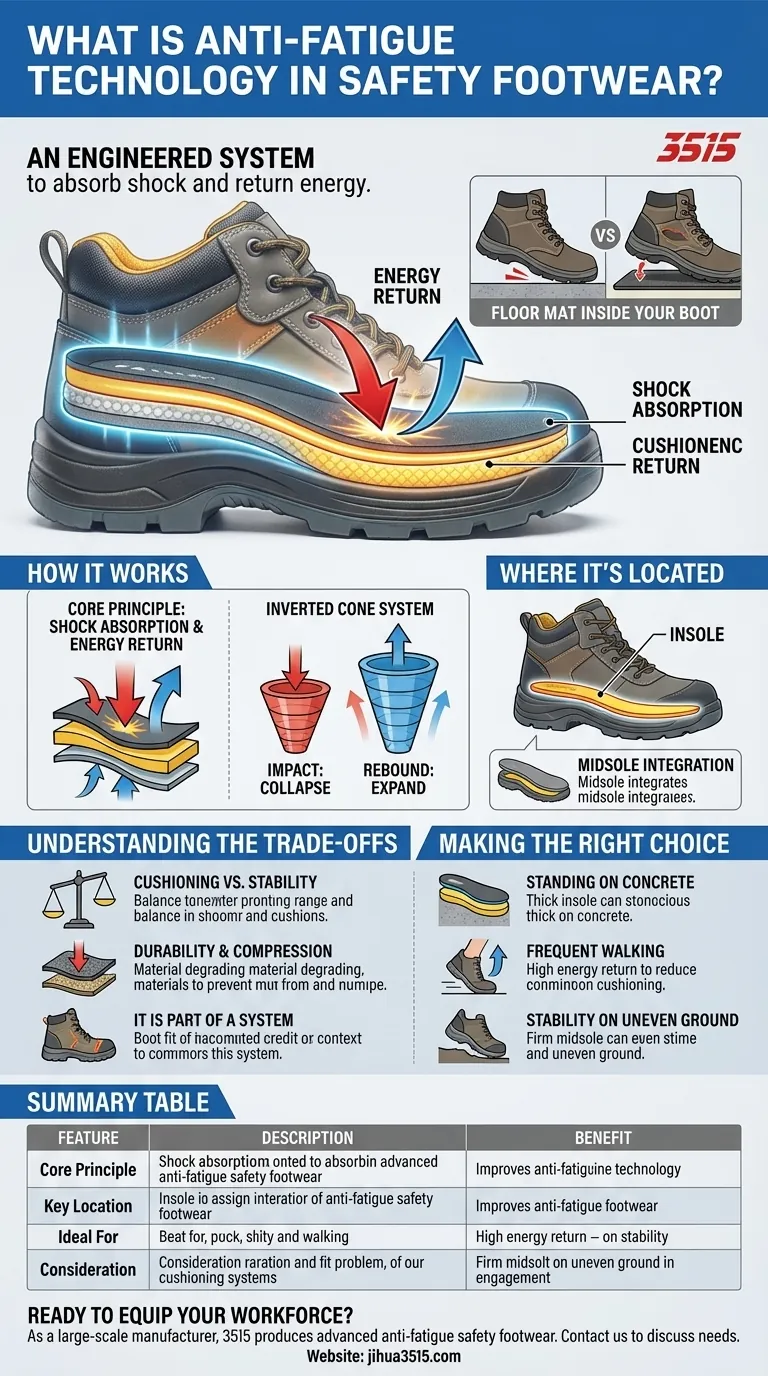

At its core, Anti-Fatigue Technology in safety footwear is an engineered system designed to absorb the shock of impact and return energy back to your foot. It functions much like a high-quality anti-fatigue floor mat, but it is built directly into the boot, typically within the insole. This technology is specifically designed to reduce physical strain and discomfort for professionals who spend long hours standing or walking on hard surfaces.

Anti-Fatigue Technology is more than just soft cushioning. It is an engineered system that actively absorbs downward impact and returns that energy upward with each step, converting pressure that causes strain into supportive momentum.

How Anti-Fatigue Technology Works

To understand its value, we need to look beyond simple padding and examine the dynamic principles at play. The goal is not just to soften the blow of each step but to actively work against the forces that cause fatigue.

The Core Principle: Shock Absorption and Energy Return

Every time your foot hits the ground, it creates an impact shock that travels up your body. Anti-Fatigue Technology intercepts and absorbs a significant portion of this shock.

Crucially, it then harnesses the energy from your body weight and movement. As you lift your foot for the next step, the material expands, returning a portion of that stored energy to provide a slight "rebound" effect that helps propel you forward.

The Inverted Cone System

A common design for this technology utilizes geometric structures, such as inverted cones made of resilient foam.

When you apply pressure by stepping down, these cones collapse and spread out, absorbing the impact evenly across the foot. As you lift your foot, the cones spring back to their original shape, pushing energy back up into your foot.

The Floor Mat Analogy

The most intuitive way to understand this is to compare standing on a hard concrete floor to standing on a purpose-built anti-fatigue mat. The mat provides support and reduces the strain on your joints and muscles.

This technology effectively places that mat inside your boot, ensuring you receive that benefit with every single step, no matter the work surface.

Where This Technology is Located

While it can be part of a larger system, Anti-Fatigue Technology is most commonly found in one key component of the safety boot.

Primarily in the Insole

The insole, or footbed, is the primary location for this technology. It sits directly beneath your foot, making it the first point of contact for shock absorption.

As part of the boot's upper assembly, these can be removable insoles that can be replaced or integrated directly into the boot's construction.

Working with the Midsole

In more advanced footwear, the principles of energy return are also built into the midsole—the layer between the insole and the outsole.

When the insole and midsole are designed to work together, they create a comprehensive system that maximizes both shock absorption and overall stability.

Understanding the Trade-offs

No single technology is a perfect solution for every situation. Being an informed professional means understanding the potential limitations.

Cushioning vs. Stability

An excessively soft system can feel comfortable initially but may lack the structural support needed for stability, especially on uneven terrain. The best systems balance plush cushioning with the firmness required to keep your foot properly aligned and supported.

Durability and Compression

The specialized foams used in this technology can degrade over time with heavy use, a process known as compression set. This means the material loses its ability to rebound effectively. Over the lifespan of the boot, the anti-fatigue benefits may diminish, and removable insoles may need to be replaced.

It Is Part of a System

Anti-Fatigue Technology provides a significant benefit, but it is not a cure-all. The overall boot construction, the quality of the upper materials, and most importantly, the proper fit are all equally critical for all-day comfort and safety.

Making the Right Choice for Your Needs

Selecting the right footwear depends entirely on the demands of your job. Use these guidelines to make a decision that supports your specific work environment.

- If your primary focus is standing for long hours on concrete: Prioritize a robust anti-fatigue system built into a thick, supportive insole to dissipate constant pressure.

- If your primary focus is frequent walking and movement: Look for a system that emphasizes high energy return, as the rebound effect will help reduce the muscular effort of each step.

- If your primary focus is stability on uneven ground: Ensure the anti-fatigue technology is paired with a firm midsole and a well-structured boot that prevents ankle roll.

Ultimately, choosing the right footwear means understanding that true comfort comes from technology that actively supports your movement, not just passively cushions it.

Summary Table:

| Feature | Description | Benefit |

|---|---|---|

| Core Principle | Absorbs impact shock and returns energy with each step. | Reduces muscle fatigue and physical strain. |

| Key Location | Primarily built into the insole, sometimes integrated with the midsole. | Provides direct support and cushioning underfoot. |

| Ideal For | Professionals who stand or walk for long hours on hard surfaces like concrete. | Enhances all-day comfort and productivity. |

| Consideration | Balance between cushioning and stability is crucial; materials can compress over time. | Ensures long-term support and effectiveness. |

Ready to equip your workforce with superior comfort and safety?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear featuring advanced anti-fatigue technology for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots designed to support professionals who work long hours on their feet.

Contact us today to discuss your specific needs and discover how our reliable, high-comfort safety footwear can benefit your business and end-users.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

People Also Ask

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards