Choosing the right work boot is a critical safety decision, not a simple purchase. The best choice is not determined by brand or price, but by a methodical assessment of your specific job hazards, comfort needs, and durability requirements. Key factors include the type of protective toe, the boot's material, its electrical-hazard rating, and its outsole's resistance to slips and oils.

The most common mistake is choosing a boot before fully understanding the problem it needs to solve. Begin by analyzing the specific risks of your work environment—from impact dangers to electrical currents—and then select the boot with the precise features designed to mitigate them.

The Foundation: Assessing Your Work Environment

Before looking at a single boot, you must first become an expert on the dangers you face every day. The right boot is a piece of personal protective equipment (PPE) tailored to your specific occupational risks.

Identify Job-Specific Hazards

Nearly a quarter of all workplace accidents result in injuries to the feet, ankles, or knees. A thorough hazard assessment is the first step in prevention.

Consider the primary risks. Do you work with heavy materials that could fall or roll onto your feet? Do you walk on surfaces that are frequently oily or wet? Are you exposed to live electrical circuits or sharp objects from below?

Understand Required Safety Standards

Professional work boots are rated to meet specific safety criteria. In the United States, the Occupational Safety and Health Administration (OSHA) sets the guidelines for employers, while ASTM International (formerly American Society for Testing and Materials) provides the performance standards for footwear.

Boots that meet these standards will be labeled, indicating their specific protective capabilities, such as impact resistance or electrical hazard protection. Always ensure your footwear complies with your industry's requirements.

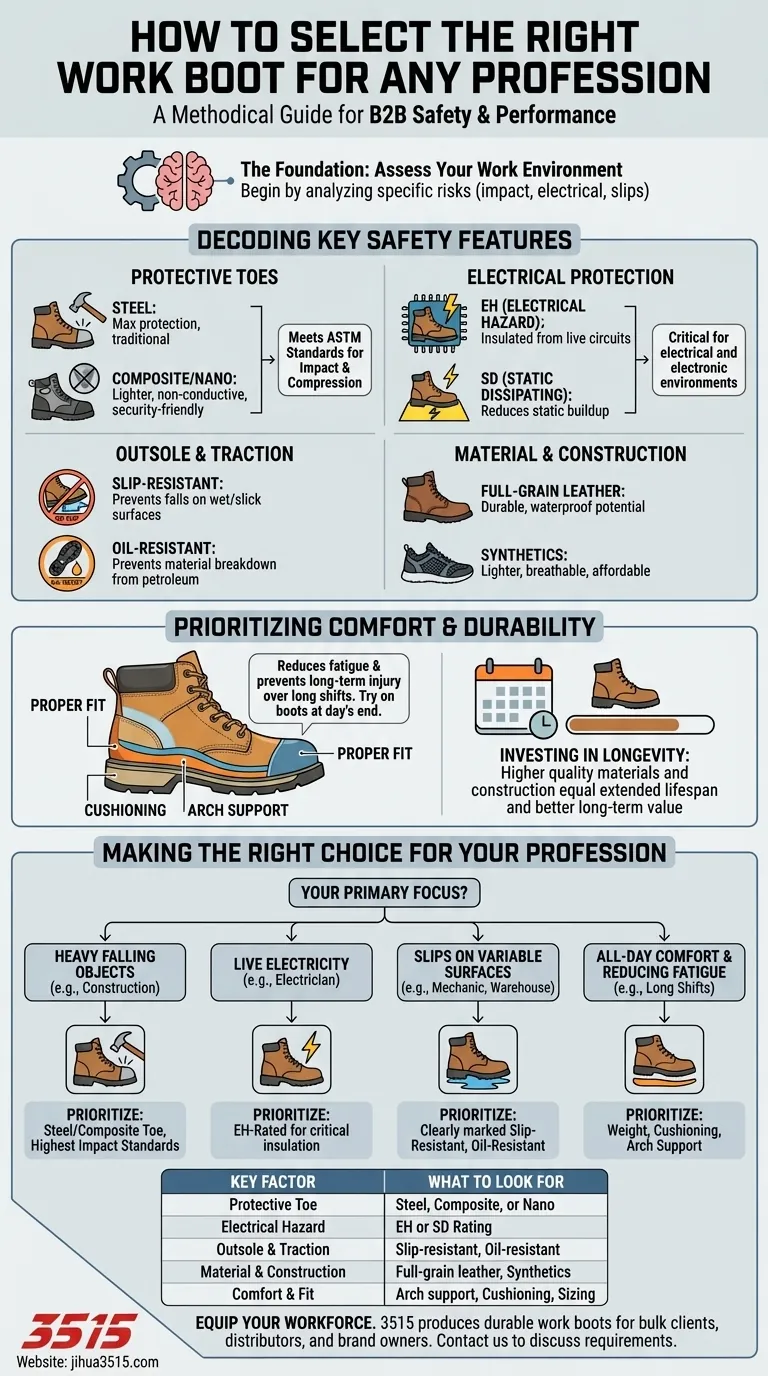

Decoding Key Safety Features

Once you understand your environment's hazards, you can match them to the corresponding safety features. Each feature is engineered to counter a specific type of risk.

Protective Toes: Steel vs. Composite

The safety toe is the classic feature of a work boot, designed to protect you from impact and compression.

Steel toes offer maximum protection and are the traditional standard. Composite toes, made from materials like carbon fiber, Kevlar, or plastic, are lighter, do not conduct cold or heat, and won't set off metal detectors. A newer option, the nano toe, is an extremely lightweight composite that still meets high safety standards.

Electrical Protection: EH vs. SD

For those working around electricity, the right boot is non-negotiable.

Electrical Hazard (EH) rated boots are designed with non-conductive soles and heels to protect you from accidental contact with live electrical circuits. In contrast, Static Dissipating (SD) boots are built to reduce the buildup of static electricity, protecting sensitive electronic equipment from damage.

Outsole and Traction

The outsole is your boot's connection to the ground. A slip-resistant sole is crucial for preventing falls on wet or slick surfaces.

For mechanics, machinists, and others working around machinery, an oil-resistant sole is equally important, as it prevents the material from breaking down when exposed to petroleum products.

Material and Construction

The boot's upper material determines its durability, breathability, and resistance to the elements. Full-grain leather is highly durable and can be made waterproof, while synthetic materials often offer a lighter, more breathable, and sometimes more affordable alternative.

Construction details matter immensely. A welder, for instance, benefits from a taller, 8-inch leather boot with no laces to prevent hot embers from causing burns.

Prioritizing Comfort and Durability

A safe boot is only effective if it's worn properly, and comfort is key to ensuring that. Since you spend hours in your boots, features that reduce fatigue are just as important as those that prevent acute injury.

The Importance of Proper Fit

A poorly fitting boot can cause pain, blisters, and long-term foot problems. Always try on boots at the end of the day, as your feet naturally swell. Ensure there is enough room in the toe box while keeping your heel securely in place.

Cushioning and Arch Support

Look for adequate cushioning in the midsole and a supportive insole. Proper arch support is critical for aligning your body and reducing strain on your feet, knees, and back over a long shift.

Investing in Longevity

Durability is a function of both materials and construction quality. While a higher-quality boot may cost more upfront, its extended lifespan often makes it a better long-term investment, saving you money and ensuring continuous protection.

Understanding the Trade-offs

Selecting the perfect work boot always involves balancing competing priorities. Being aware of these trade-offs allows you to make a more informed decision based on what matters most for your job.

Safety vs. Weight

More protective features, like steel toes and puncture-resistant plates, inevitably add weight. While a heavier boot might offer more security, it can also lead to greater fatigue. Composite materials can lighten the load but may come at a higher cost.

Durability vs. Cost

The most durable boots are typically made from premium materials like full-grain leather with high-quality stitching. These boots command a higher price but will outlast cheaper alternatives, providing better value over their lifespan.

Specialized Features vs. Versatility

A boot designed for a highly specific task, like a logger's boot with high caulks, is perfect for its intended environment but impractical for walking on concrete. Be honest about your daily tasks and choose a boot that covers your most common needs.

Making the Right Choice for Your Profession

Your goal should be to find the ideal intersection of protection, comfort, and durability for your specific role. Use your hazard assessment to guide your final choice.

- If your primary focus is protection from heavy falling objects (e.g., construction, manufacturing): Prioritize a boot with a steel or composite toe that meets the highest ASTM standards for impact and compression.

- If your primary focus is working around live electricity (e.g., electrician): Ensure your boots are explicitly EH-rated to provide critical insulation against shock.

- If your primary focus is preventing slips on variable surfaces (e.g., mechanic, warehouse): Look for an outsole that is clearly marked as slip-resistant and, if necessary, oil-resistant.

- If your primary focus is all-day comfort and reducing fatigue (e.g., long shifts on concrete): Pay close attention to the boot's weight, cushioning, and arch support to prevent long-term strain.

Investing in the right work boot is a direct investment in your daily safety and long-term well-being.

Summary Table:

| Key Factor | What to Look For |

|---|---|

| Protective Toe | Steel, Composite, or Nano for impact/compression protection. |

| Electrical Hazard | EH (Electrical Hazard) or SD (Static Dissipating) rating. |

| Outsole & Traction | Slip-resistant and oil-resistant soles for stability. |

| Material & Construction | Full-grain leather for durability, synthetics for breathability. |

| Comfort & Fit | Proper arch support, cushioning, and correct sizing for all-day wear. |

Ready to equip your workforce with the perfect safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable work boots and shoes for distributors, brand owners, and bulk clients. Whether your team needs steel-toe boots for construction, EH-rated footwear for electricians, or comfortable, slip-resistant soles for warehouse staff, we have the production capabilities and expertise to meet your exact specifications.

Let's discuss your requirements and get a quote for your next order.

Contact 3515 today for a consultation

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Sport Style Safety Boots for Bulk Orders

- Premium Waterproof High-Cut Industrial Safety Boots for Wholesale and Bulk Orders

People Also Ask

- Why is the use of professional safety shoes critical for injection molding? Prevent Injuries with High-Impact Footwear

- What protective functions do industrial safety shoes provide for utility technicians? Stability & Electrical Insulation

- Why is hydrophobic waterproof leather commonly utilized in the construction of fire safety boots? Essential Protection

- What is the primary function of industrial safety shoes in polymer recycling? Protect Against Machinery & Sharp Debris

- What are the primary protective functions of professional-grade safety shoes? Enhance Safety in Heavy Industry