At its core, PVC is a synthetic plastic used to create a specific type of protective footwear often categorized as "rubber boots." Polyvinyl Chloride (PVC) is a versatile polymer that, when made flexible, can be molded into a single, seamless boot that is completely waterproof, lightweight, and more affordable than traditional rubber alternatives.

While often grouped with "rubber boots," PVC boots are a distinct category of footwear. Their key advantage lies in providing excellent waterproof and chemical protection at a lower cost, but this comes with trade-offs in long-term durability and flexibility in cold weather.

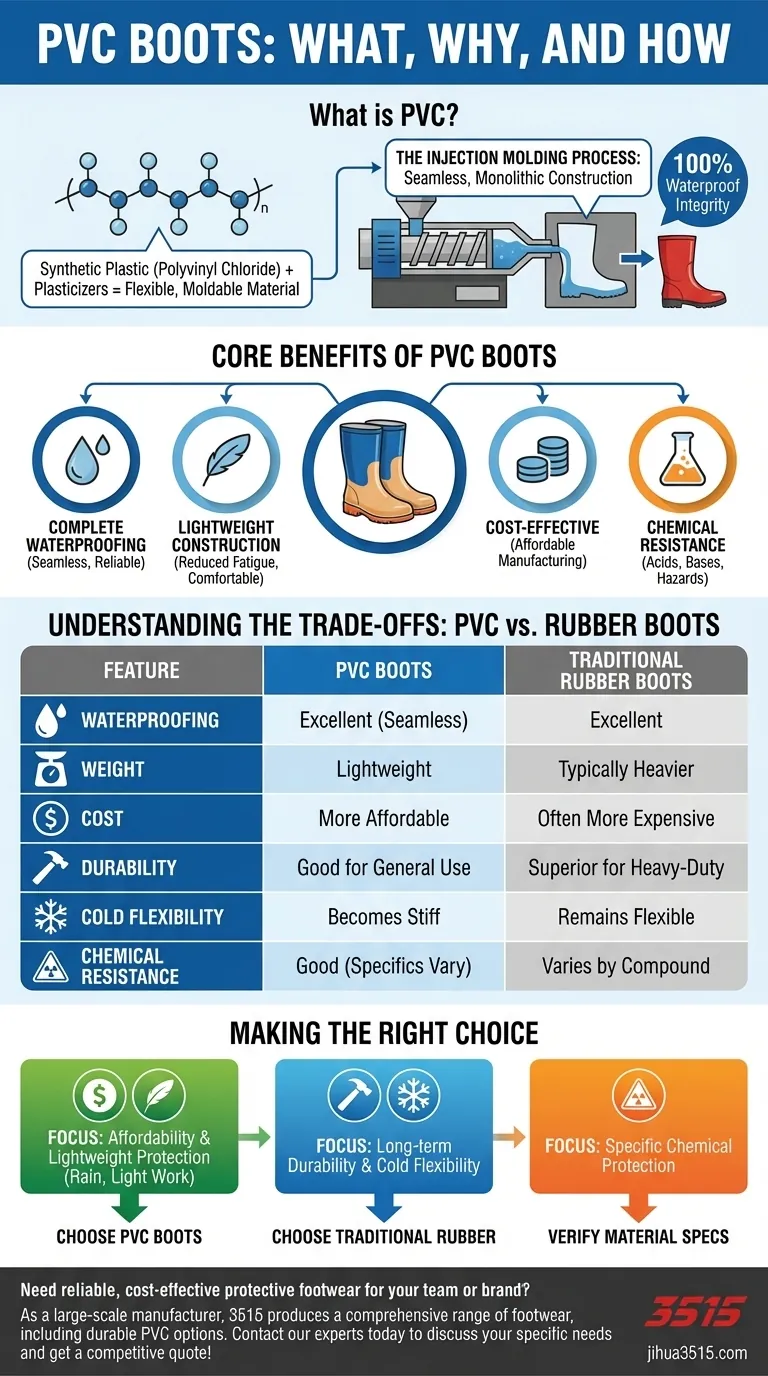

The Role of PVC in Protective Footwear

PVC boots are not made from rubber; they are a plastic-based alternative manufactured through a distinct process that gives them unique characteristics. Understanding this process is key to appreciating their function.

A Versatile Synthetic Polymer

Polyvinyl Chloride is one of the most widely produced synthetic plastic polymers in the world. In its rigid form, it's used for pipes and construction materials.

However, by adding plasticizers, it becomes flexible and soft, making it an ideal material for injection molding into footwear.

The Injection Molding Process

PVC boots are created by heating the polymer and injecting it into a boot-shaped mold. As the PVC cools, it solidifies into a single, seamless piece.

This monolithic construction is the reason for their absolute waterproof integrity. There are no stitches or glued seams that can fail and allow water to penetrate.

Core Benefits of PVC Boots

The use of PVC offers several clear advantages, particularly in industrial, agricultural, and general-use wet-weather applications.

Complete Waterproofing

Because they are formed in one piece, PVC boots are 100% waterproof right out of the box. This makes them highly reliable for keeping feet dry in wet and muddy conditions.

Lightweight Construction

Compared to many traditional rubber boots, PVC boots are significantly lighter. This reduces foot fatigue, making them more comfortable for long work hours or extended wear.

Cost-Effectiveness

PVC is generally less expensive to produce and manufacture than high-quality natural rubber or neoprene. This benefit is passed on to the consumer, making PVC boots a highly affordable option.

Chemical Resistance

PVC offers strong resistance to a variety of acids, bases, and other chemicals. This makes it a suitable material for Haz-Mat boots and protective footwear in many industrial settings.

Understanding the Trade-offs: PVC vs. Rubber

While PVC offers many benefits, it is crucial to understand its limitations, especially when comparing it to traditional rubber boots. Choosing the right material depends entirely on your specific needs and environment.

Durability and Longevity

The primary trade-off is durability. PVC is generally less resistant to abrasion and punctures than high-quality rubber and may deteriorate more quickly with heavy use.

Flexibility in Cold Temperatures

PVC has a tendency to become stiff and rigid in cold weather. This lack of flexibility can make the boots feel uncomfortable and may even lead to cracking over time in freezing environments.

Environmental Impact

As a synthetic plastic, PVC is not biodegradable. This is a significant environmental consideration compared to boots made from natural rubber.

Making the Right Choice for Your Goal

Selecting the correct boot material is about matching its properties to your intended use and environment.

- If your primary focus is affordability and lightweight protection for wet conditions: PVC boots offer an excellent value proposition for rain, gardening, or light industrial work.

- If your primary focus is long-term durability and flexibility in cold climates: Investing in a traditional, high-quality rubber boot is likely the better choice.

- If your primary focus is protection against specific industrial chemicals: Always verify the boot's material specifications and resistance ratings for the specific hazards you face.

Ultimately, understanding the distinct properties of PVC empowers you to choose the right tool for the job, ensuring your footwear meets the demands of your environment.

Summary Table:

| Feature | PVC Boots | Traditional Rubber Boots |

|---|---|---|

| Waterproofing | Excellent (seamless construction) | Excellent |

| Weight | Lightweight | Typically Heavier |

| Cost | More Affordable | Often More Expensive |

| Durability | Good for general use | Superior for heavy-duty use |

| Cold Weather Flexibility | Becomes stiff | Remains flexible |

| Chemical Resistance | Good resistance to many chemicals | Varies by compound |

Need reliable, cost-effective protective footwear for your team or brand?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including durable PVC options perfect for your market.

We can help you source or create the ideal waterproof boots that balance performance, comfort, and value.

Contact our experts today to discuss your specific needs and get a competitive quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

People Also Ask

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?