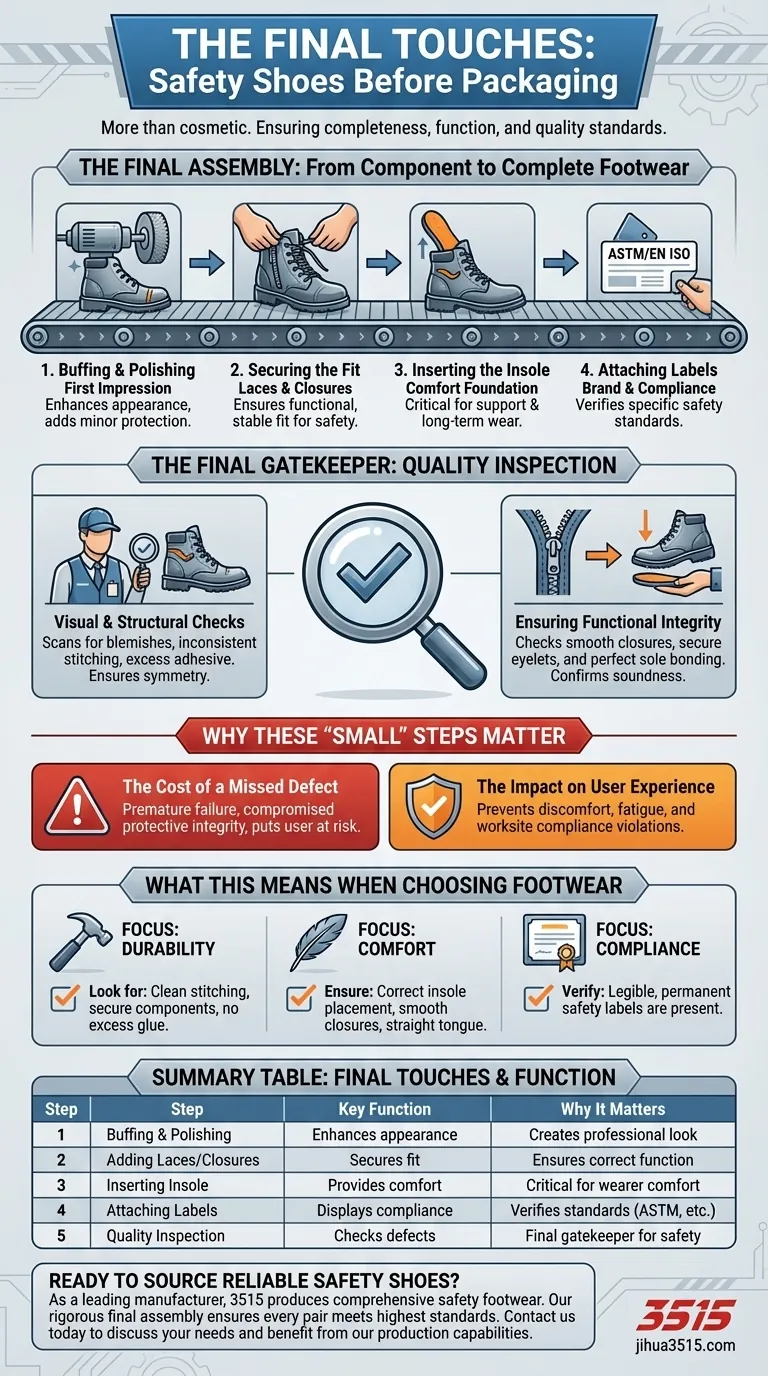

Before being packaged, safety shoes undergo a series of critical final touches to ensure they are complete, functional, and meet quality standards. These steps include buffing and polishing the exterior, adding functional closures like laces or zippers, inserting the insole for comfort, and attaching all necessary branding and compliance labels before a final quality inspection.

These finishing steps are more than just cosmetic. They represent the final transition from a manufactured object to a complete, user-ready piece of personal protective equipment, with a final quality check acting as the gatekeeper for safety and reliability.

The Final Assembly: From Component to Complete Footwear

The last stage of manufacturing focuses on assembling the final components and preparing the shoe for the end-user. Each step has a specific function that contributes to the final product's quality and performance.

Buffing and Polishing: The First Impression

After the main construction is complete, the shoes are cleaned, buffed, and polished. This process not only creates a professional, finished appearance but can also help treat the leather or synthetic materials, adding a minor layer of protection.

Securing the Fit: Laces and Closures

Laces, zippers, or other fastening systems are added to the shoe. This step ensures the shoe is functionally complete, allowing the user to secure it properly for a safe and stable fit.

The Foundation of Comfort: Inserting the Insole

The insole, a key component for comfort and support, is placed inside the shoe. This is one of the last elements added, ensuring the interior is clean and correctly configured for the wearer's foot.

Brand and Compliance: Attaching Labels

Finally, all necessary labels are attached. These include brand markings, sizing information, and, most importantly, the specific safety standard compliance labels (e.g., ASTM, EN ISO) that certify the shoe's protective capabilities.

The Final Gatekeeper: Quality Inspection

Before a single shoe is placed in a box, it undergoes a rigorous final inspection. This is arguably the most critical step in the finishing process.

Visual and Structural Checks

Inspectors meticulously scan each shoe for any visual defects. This includes looking for blemishes in the material, inconsistent stitching, or any excess adhesive. They ensure all components are attached symmetrically and securely.

Ensuring Functional Integrity

The inspection goes beyond looks. An inspector will check that zippers function smoothly, that eyelets are secure, and that the sole is perfectly bonded to the upper. This confirms the shoe is not just visually acceptable but structurally sound and ready for use.

Why These "Small" Steps Matter

Skipping or rushing these final touches can have significant consequences that undermine the purpose of the safety footwear.

The Cost of a Missed Defect

A small, missed defect like a weak seam or a poorly bonded sole can lead to premature failure in the field. This compromises the shoe's protective integrity and can put the user at risk.

The Impact on User Experience

An incorrectly inserted insole can cause discomfort and fatigue. A missing compliance label can cause a worksite violation. These details, while small, directly impact the user's safety, comfort, and ability to use the product as intended.

What This Means When Choosing Footwear

Understanding this final process helps you assess the quality of a potential purchase.

- If your primary focus is durability: Look for clean stitching, a lack of excess glue, and securely attached components, as these are hallmarks of a thorough final inspection.

- If your primary focus is comfort: Ensure the insole is correctly placed, the tongue sits straight, and all closures function smoothly without catching.

- If your primary focus is compliance: Always verify that the correct safety standard labels are present, legible, and permanently attached to the shoe.

Recognizing the care put into these final details empowers you to select safety footwear with confidence in its quality and reliability.

Summary Table:

| Final Touch Step | Key Function | Why It Matters |

|---|---|---|

| Buffing & Polishing | Enhances appearance and material protection | Creates a professional look and adds durability |

| Adding Laces/Closures | Secures fit for stability and safety | Ensures the shoe functions correctly for the user |

| Inserting the Insole | Provides comfort and support | Critical for wearer comfort and long-term use |

| Attaching Labels | Displays branding and safety certifications | Verifies compliance with ASTM, EN ISO, etc. |

| Final Quality Inspection | Checks for visual and structural defects | Acts as the final gatekeeper for safety and reliability |

As a leading manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our rigorous final assembly and inspection process ensures every pair meets the highest standards for durability, comfort, and compliance.

Ready to source reliable safety shoes? Contact us today to discuss your specific needs and benefit from our extensive production capabilities.

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium Sport Style Safety Boots for Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

People Also Ask

- What are the core safety features of industrial safety shoes? Expert Guide for Bridge & Heavy Machinery Safety

- What are some hazards that can cause slips and falls in the workplace? Prevent Costly Injuries & Boost Safety

- What are the OSHA recommendations for wearing protective footwear? A Legal Guide to Workplace Foot Safety

- What are the advantages of rubber soles for work boots? Unbeatable Grip & Durability

- What does CE-approval indicate for safety boots? Your Guide to EU-Compliant Footwear Protection