For a mechanic, the right work boot is not an option; it's a critical piece of personal protective equipment. The essential features are a certified slip-resistant sole to handle oily and wet surfaces, a safety toe (steel or composite) to protect against impacts from dropped tools and parts, and substantial cushioning to combat fatigue from long hours on concrete floors.

A mechanic's work boot is a specialized system designed for the unique hazards of a modern garage. The goal is not just to find a "tough" boot, but one that specifically counters slick fluids, impact risks, electrical hazards, and the physical strain of standing on concrete all day.

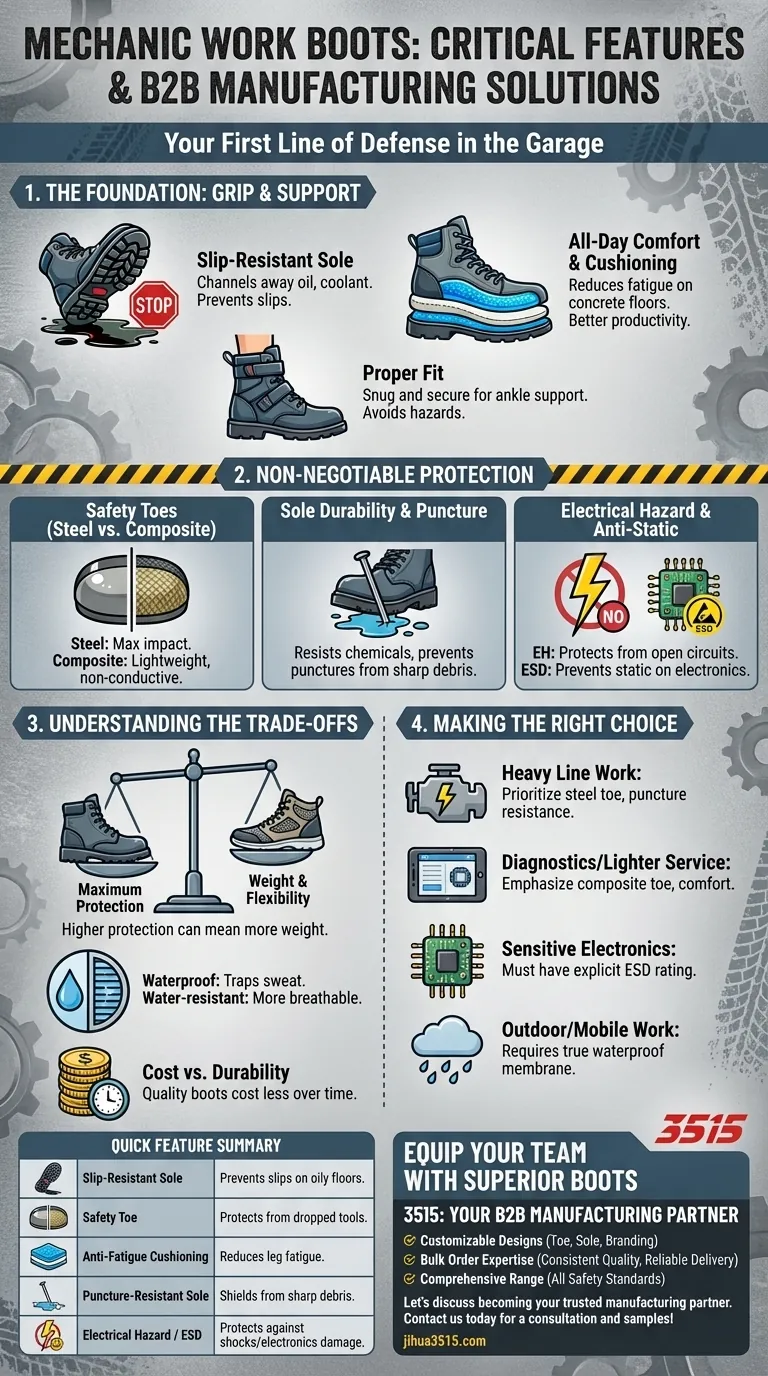

The Foundation: Grip and Support on Unforgiving Surfaces

The primary function of any work boot is to provide a stable, safe connection to the ground. For a mechanic, the ground is an often unpredictable and unforgiving surface.

The Critical Role of Slip-Resistant Soles

A standard boot sole is not sufficient for a garage environment. You need a sole specifically rated for slip resistance, designed to channel away oil, coolant, and other fluids to maintain grip. This is your first line of defense against slips and falls.

All-Day Comfort and Cushioning

Standing on concrete for 8-10 hours a day places enormous strain on your feet, knees, and back. Look for boots with significant cushioning and anti-fatigue technology in the midsole and insole. This feature directly translates to less pain and more productivity.

The Importance of a Proper Fit

An improperly fitting boot is a safety hazard. A boot that is too loose can cause tripping, while one that is too tight can lead to long-term foot injuries. Your boots should feel snug and secure with adjustable fastening, providing ankle support without restricting necessary movement.

Non-Negotiable Protection for the Garage

Beyond stability, your boots must actively shield you from the specific dangers present in an auto shop.

Safety Toes: Steel vs. Composite

Protection against falling objects is mandatory. Steel toes offer the maximum protection against impact and compression. Composite toes, made from materials like carbon fiber or Kevlar, are lighter and do not conduct heat, cold, or electricity, making them an excellent choice for general repair work. Both should meet national safety standards (like ASTM F2413 in the U.S.).

Sole Durability and Resistance

The sole needs to be more than just slip-resistant. It must be made from a durable compound that can withstand exposure to chemicals and oils without degrading. Puncture resistance is also a key feature, protecting you from sharp metal shavings or dropped tools on the floor.

Electrical Hazard (EH) and Anti-Static (ESD) Ratings

Modern vehicles are packed with sensitive electronics. Anti-static or Electrostatic Dissipative (ESD) boots prevent the buildup of static electricity, protecting delicate components. Conversely, an Electrical Hazard (EH) rating means the boot has non-conductive soles that can protect you from open circuits.

Understanding the Trade-offs

Choosing the perfect boot involves balancing competing features. Understanding these compromises is key to making an intelligent decision.

Protection vs. Weight and Flexibility

The most protective boots, often with steel toes and thick puncture-proof plates, are also the heaviest. This added weight can increase fatigue over a long day. Evaluate your daily tasks to decide if maximum protection is worth the trade-off in weight and reduced flexibility.

Waterproofing: A Double-Edged Sword

A fully waterproof boot (marked with "WR") is great for keeping water out, but it can also trap sweat in. This can lead to discomfort and blisters. For most indoor garage work, a water-resistant boot ("WRU") that is more breathable is often a better compromise.

Cost vs. Durability

It can be tempting to save money on footwear, but cheap work boots often use inferior materials that break down quickly, especially when exposed to garage chemicals. Investing in a high-quality, durable boot from a reputable brand almost always costs less in the long run.

Making the Right Choice for Your Work

Select your boots based on the most common demands of your specific job.

- If your primary focus is heavy line work with engines and transmissions: Prioritize a certified steel toe for maximum impact protection and a highly durable, puncture-resistant sole.

- If your primary focus is diagnostics and lighter service: Emphasize a lightweight composite toe, superior anti-fatigue cushioning, and greater flexibility for comfort.

- If you frequently work with sensitive vehicle electronics: A boot with an explicit ESD rating is a critical feature to prevent component damage.

- If you work in a mobile capacity or in a shop exposed to the elements: A boot with a true waterproof (WR) membrane becomes a non-negotiable requirement.

Your boots are the most important tool you wear every single day; invest in their quality accordingly.

Summary Table:

| Key Feature | Why It Matters for Mechanics |

|---|---|

| Slip-Resistant Sole | Provides grip on oily, wet garage floors to prevent slips and falls. |

| Safety Toe (Steel/Composite) | Protects feet from impacts of dropped tools and heavy parts. |

| Anti-Fatigue Cushioning | Reduces foot and leg fatigue from long hours standing on concrete. |

| Puncture-Resistant Sole | Shields feet from sharp debris like metal shavings on the shop floor. |

| Electrical Hazard (EH) / ESD Rating | Protects against electrical shocks or prevents damage to vehicle electronics. |

Ready to Equip Your Team with Superior Work Boots?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, safety-compliant footwear specifically designed for the demanding environment of auto shops and garages. We provide the exact features mechanics need—from certified safety toes to advanced anti-fatigue technology—ensuring all-day protection and comfort.

Our capabilities are tailored for distributors, brand owners, and bulk clients:

- Customizable Designs: We can tailor boots to your specific requirements, including different safety toe options, sole compounds, and branding.

- Bulk Order Expertise: We efficiently handle large-volume orders, ensuring consistent quality and reliable delivery for your business.

- Comprehensive Range: Our production capabilities encompass all types of safety shoes and boots, meeting various international safety standards.

Let's discuss how we can become your trusted manufacturing partner. Contact us today for a consultation and to request samples!

Visual Guide

Related Products

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What are the common problems with steel toe boots? How to Prevent Foot Pain & Fatigue

- What is the importance of choosing the right size for steel toe boots? Avoid Injury and Boost Productivity

- What types of safety toe boots are available for different job requirements? Choose the Right Protection for Your Work

- What are the consequences of not wearing safety shoes? Protect Your Feet from Severe Workplace Injuries

- How can one prevent blisters when wearing steel toe boots? A Complete Guide to Pain-Free Workdays