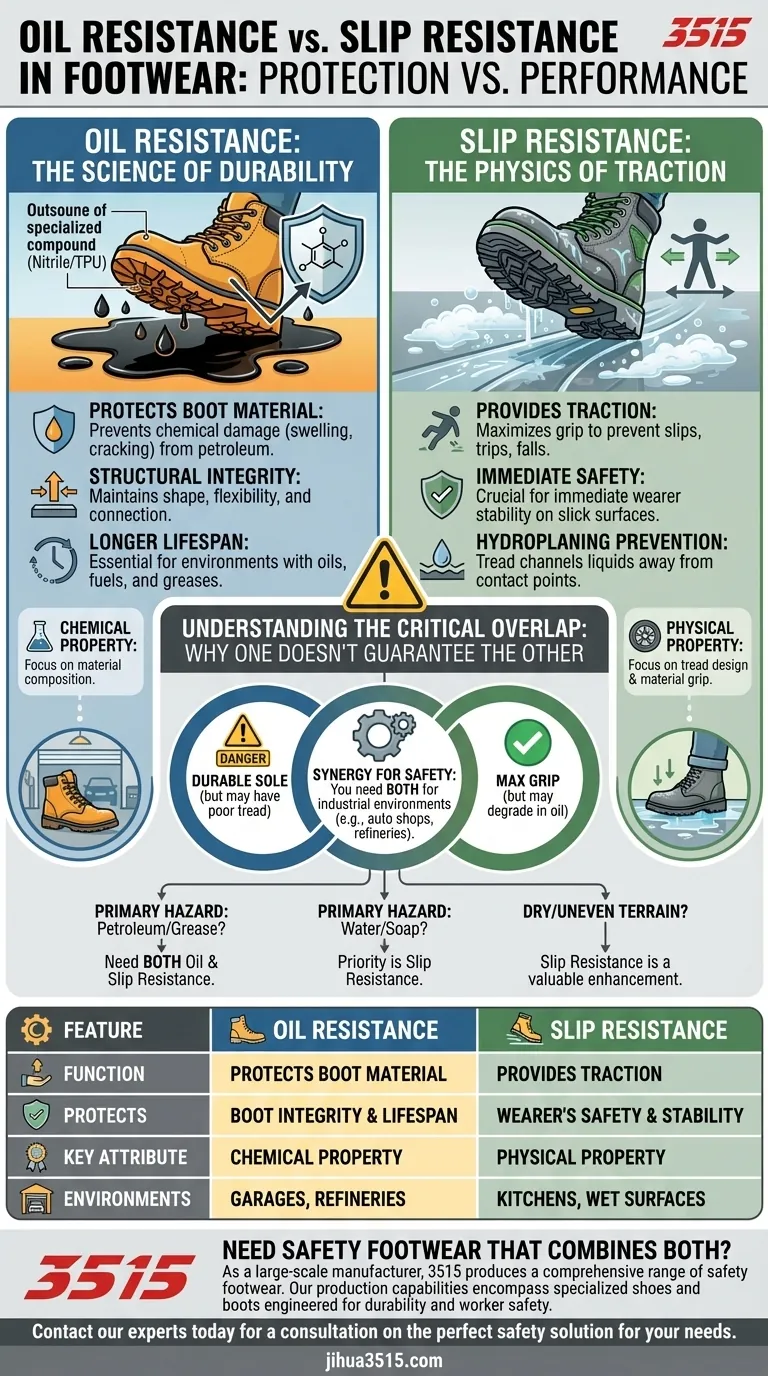

The fundamental difference is protection versus performance. Oil resistance is a feature that protects the boot’s material from being damaged by petroleum-based substances, ensuring its durability. Slip resistance is a performance feature that gives the wearer traction and helps prevent falls on slick surfaces, which may include those covered in oil.

Oil resistance concerns the footwear's structural integrity and lifespan when exposed to chemicals. Slip resistance concerns the wearer's immediate safety and stability on hazardous surfaces. They are two separate safety functions that are not interchangeable.

What is Oil Resistance? The Science of Durability

Oil resistance is a chemical property of the footwear's outsole. It's about making sure the boot itself can survive in environments where oils, fuels, and greases are present.

Protecting the Outsole Material

Many common outsole materials, like standard rubber or PVC, can be damaged by petroleum-based products. These chemicals can cause the material to swell, harden, crack, or even begin to dissolve over time.

The Mechanism of Resistance

Oil-resistant outsoles are typically made from specialized compounds like nitrile or certain types of thermoplastic polyurethane (TPU). These materials are formulated to be non-reactive to hydrocarbons, preventing chemical degradation.

This resistance ensures the outsole maintains its intended shape, flexibility, and connection to the rest of the boot, preserving its structural integrity for a longer service life.

What is Slip Resistance? The Physics of Traction

Slip resistance is a physical property of the footwear's outsole. It is entirely focused on maximizing grip between the boot and the walking surface to prevent slips, trips, and falls.

Maximizing Surface Grip

This feature is achieved through two primary factors: the outsole material and the tread pattern. The material is often a softer, "grippier" compound that creates more friction with the ground.

The Importance of Tread Design

The tread pattern is engineered to channel liquids—like water, soap, or oil—away from the sole's contact points. These channels prevent a layer of liquid from forming between the boot and the floor, a phenomenon known as hydroplaning, which is a major cause of slips.

Understanding the Critical Overlap

While they are distinct features, oil resistance and slip resistance often need to work together in hazardous environments. The presence of one does not guarantee the other.

Why One Doesn't Guarantee the Other

A boot can have a highly durable, oil-resistant sole that has a flat, poorly designed tread, making it extremely dangerous on a wet or oily floor.

Conversely, a boot could have an excellent, high-traction slip-resistant tread that will quickly fall apart if used in a garage where it's regularly exposed to oils it wasn't designed to handle.

The Synergy of Both Features

For maximum safety in industrial settings like auto shops, refineries, or factory floors, you need both. Oil resistance ensures the boot remains functional, allowing the slip-resistant tread design to do its job effectively and keep you upright.

Making the Right Choice for Your Environment

To select the correct footwear, you must first assess the specific hazards of your workspace.

- If your primary focus is working with petroleum, grease, or industrial chemicals: You must select footwear that is explicitly rated for both oil resistance and slip resistance.

- If your primary focus is working on surfaces slick with water or soap (e.g., kitchens, food processing): Your absolute priority is a high rating for slip resistance; oil resistance is a secondary benefit.

- If your primary focus is working in dry environments with uneven terrain: Neither feature may be a top priority, but slip resistance is always a valuable safety enhancement against unexpected spills.

Choosing the right footwear is a critical safety decision based on a clear understanding of your environment's specific hazards.

Summary Table:

| Feature | Oil Resistance | Slip Resistance |

|---|---|---|

| Primary Function | Protects the boot material from chemical damage | Provides traction to prevent slips and falls |

| What It Protects | The boot's structural integrity and lifespan | The wearer's immediate safety and stability |

| Key Attribute | Chemical property of the outsole material | Physical property of the outsole tread and material |

| Common Environments | Garages, refineries, industrial settings with oils/grease | Kitchens, food processing, any wet or slick surface |

Need safety footwear that combines both oil resistance AND slip resistance?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of specialized shoes and boots, engineered with the right materials and tread patterns to ensure durability and worker safety in your specific environment.

Contact our experts today for a consultation on the perfect safety solution for your needs.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Wholesale Customizable Safety Boots Durable & Protective Footwear Manufacturing

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job