At its core, oil-resistant footwear is specifically engineered to prevent the shoe or boot's outsole from degrading when it comes into contact with petroleum-based products. This is a critical durability feature that protects the structural integrity of the footwear, ensuring it remains safe and functional over its intended lifespan.

Oil resistance is fundamentally about preserving the boot itself. While it contributes to overall safety, its primary job is to stop oil from chemically breaking down the sole's material, which in turn helps maintain other vital features like slip resistance.

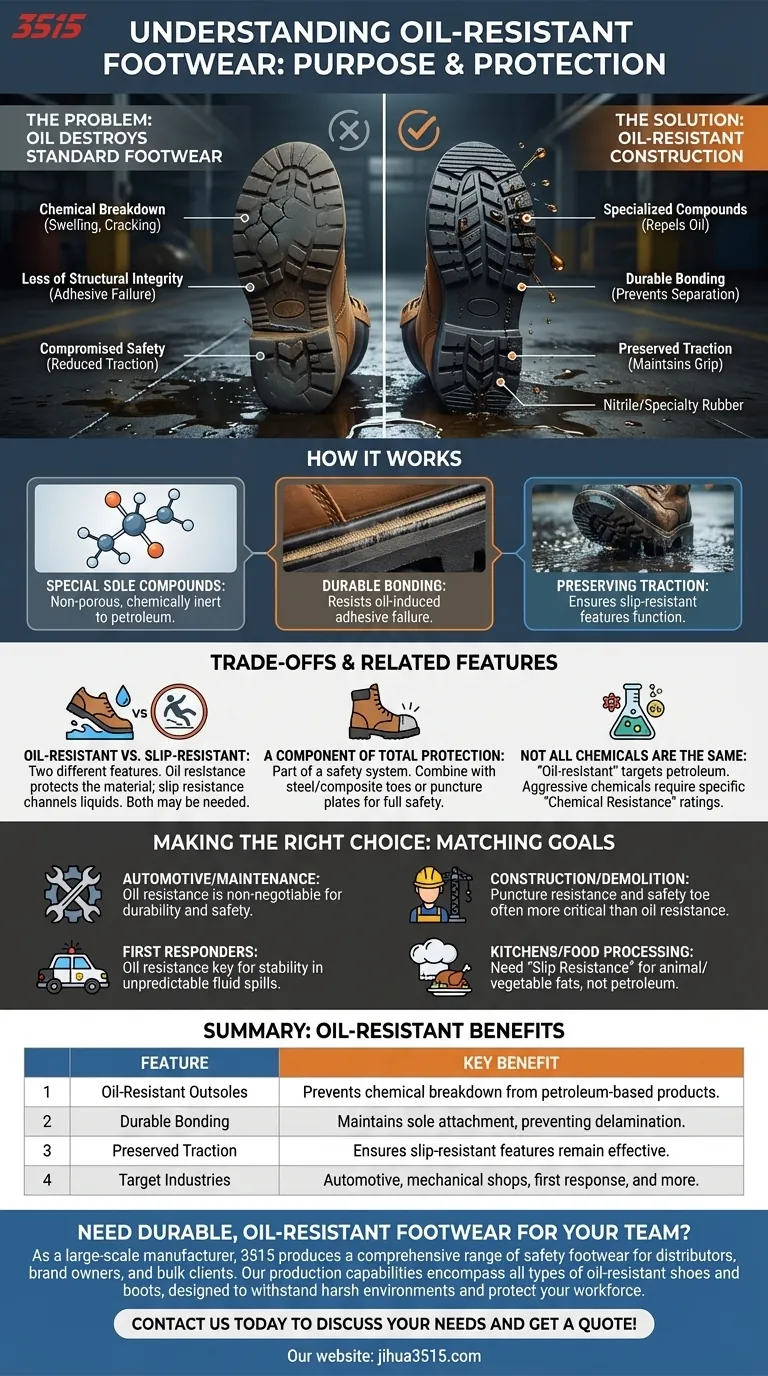

The Core Problem: How Oil Destroys Standard Footwear

Many people assume the main danger from oil is slipping, but the damage it does to the footwear itself is a more fundamental problem. Standard sole materials are vulnerable to chemical attack.

Chemical Breakdown of Materials

Oils and petroleum products can cause the rubber and plastic compounds in a standard sole to swell, soften, or become brittle and crack. This absorption process permanently changes the material's properties.

Loss of Structural Integrity

This chemical degradation doesn't just affect the sole's material; it also attacks the special glues and adhesives that bond the sole to the upper part of the boot, leading to separation and complete footwear failure.

Compromised Safety Features

When a sole softens and its tread pattern degrades, its ability to provide traction is significantly reduced. An oil-damaged boot is no longer a reliable slip-resistant boot, even if it was originally designed to be.

How Oil-Resistant Construction Works

To combat this degradation, manufacturers use specific materials and construction methods designed to withstand exposure to hydrocarbons.

Specialized Sole Compounds

Oil-resistant outsoles are made from materials like nitrile or specially formulated rubber compounds. These materials are non-porous and chemically inert to petroleum, so they don't absorb the oil and break down.

Durable Bonding

The adhesives used to construct oil-resistant footwear are also specially formulated. They maintain their bonding strength even with prolonged exposure to oil, preventing the sole from delaminating from the boot.

Preserving Traction

By resisting oil, the sole maintains its designed hardness and tread pattern. This ensures that features designed for slip resistance can continue to function effectively in challenging environments.

Understanding the Trade-offs and Related Features

It is critical to understand that "oil-resistant" is not a catch-all term for safety. It is a specific feature that addresses a specific hazard.

Oil-Resistant vs. Slip-Resistant

These are two different features. Oil resistance protects the boot's material from damage. Slip resistance refers to the outsole's tread design and its ability to channel away liquids to maintain contact with the ground. While oil-resistant boots are crucial for oily floors, you must ensure they are also rated for slip resistance.

A Component of Total Protection

Oil resistance is just one piece of the safety puzzle. Depending on the work environment, you may need additional features like steel or composite toes for impact protection or puncture-resistant plates to guard against nails and other sharp objects.

Not All Chemicals Are the Same

"Oil-resistant" specifically refers to resistance against petroleum-based products. If your workplace involves aggressive acids, solvents, or other chemicals, you will need footwear specifically rated for "chemical resistance," which is a different and higher standard of protection.

Making the Right Choice for Your Goal

Selecting the correct footwear means matching its features to your specific workplace hazards.

- If your primary focus is working in automotive, maintenance, or mechanical shops: Oil resistance is a non-negotiable feature to ensure your boots last and remain safe.

- If your primary focus is construction or demolition: You need a combination of features, with puncture resistance and a safety toe often being more critical than oil resistance, unless you frequently work around heavy machinery.

- If you are a first responder or work around traffic accidents: Oil resistance is a key feature for maintaining stability and footing in unpredictable environments with spilled automotive fluids.

- If your primary focus is working in kitchens or food processing: You need footwear rated for "slip resistance" on wet and greasy floors, where the "oils" are typically animal or vegetable fats, not petroleum.

Choosing the right boot is about understanding your environment and selecting the specific tool designed to keep you safe within it.

Summary Table:

| Feature | Key Benefit |

|---|---|

| Oil-Resistant Outsoles | Prevents chemical breakdown from petroleum-based products. |

| Durable Bonding | Maintains sole attachment, preventing delamination. |

| Preserved Traction | Ensures slip-resistant features remain effective. |

| Target Industries | Automotive, mechanical shops, first response, and more. |

Need durable, oil-resistant footwear for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of oil-resistant shoes and boots, designed to withstand harsh environments and protect your workforce.

Contact us today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

- Wholesale Leather Safety Boots with Customizable Protective Toe

People Also Ask

- How do athletic-style safety shoes balance flexibility and safety? Perfect Agility for Active Professionals

- How does the shock-absorption technology in safety footwear help reduce injury? Protect Your Skeletal Health Today

- What is the primary objective of utilizing dedicated safety shoes in nanomaterial work zones? Prevent Track-Out Now

- How do industrial safety shoes contribute to safety in sugar production? Ensure High-Altitude Inspection Security

- What is the purpose of requiring subjects to wear anti-slip socks and tight-fitting sportswear? Optimize Sensor Data