The most critical factors influencing your choice of work boot construction are your specific work environment, the physical demands of your job, and the balance you need between long-term durability and immediate comfort. The construction method directly dictates a boot's flexibility, water resistance, weight, and ability to be repaired, making it the single most important technical decision you will make.

The goal is not to find the single "best" construction method, but to perfectly align the method's inherent strengths—such as the repairability of a Goodyear welt or the flexibility of cement construction—with the daily reality of your work.

The Foundation: Understanding the Boot's Anatomy

Before comparing construction methods, it's essential to understand the two core components they connect: the upper and the outsole. The method used to join these pieces defines the boot's character.

The Role of the "Last"

Every boot is built around a last, which is a solid, foot-shaped form. This mold dictates the boot's size, width, and overall shape. A well-designed last is the foundation of comfort and proper fit, regardless of how the sole is eventually attached.

The Upper and the Outsole

The upper is the entire part of the boot that covers your foot. The outsole is the bottom layer that makes direct contact with the ground. The construction method is simply the technique used to permanently bond the upper to the outsole.

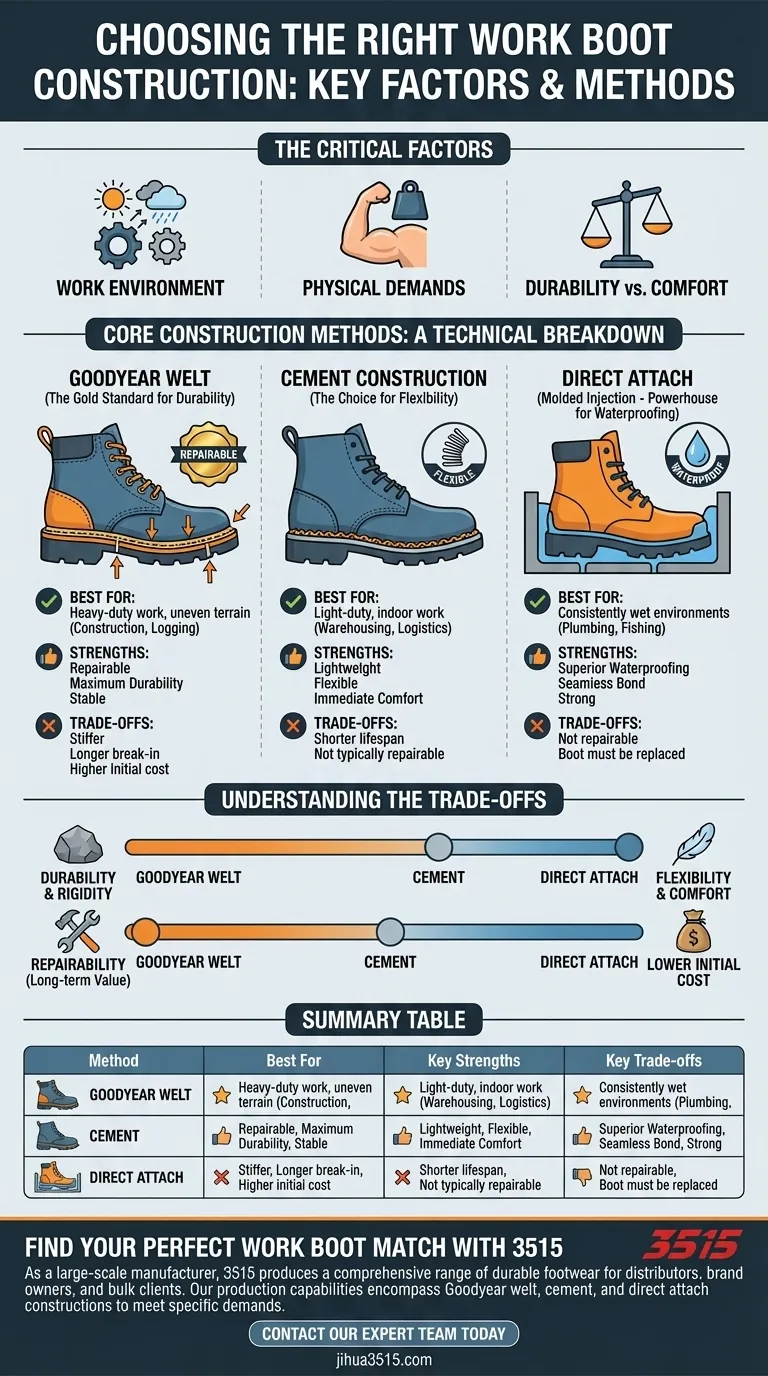

Core Construction Methods: A Technical Breakdown

There are three primary methods used in quality work boots, each with a distinct profile of strengths and weaknesses.

Goodyear Welt: The Gold Standard for Durability

This is a traditional, labor-intensive method where the upper is stitched to a leather strip called a welt. The welt is then stitched to the outsole. This creates a highly secure, layered connection.

Its primary advantage is repairability. A cobbler can simply cut the outsole stitches and attach a new sole, dramatically extending the boot's life. This method also creates a very stable, water-resistant platform.

Cement Construction: The Choice for Flexibility

In cement construction, the outsole is attached directly to the upper using a strong, industrial-grade adhesive. There is no stitching connecting the sole to the upper.

This method results in a boot that is significantly lighter and more flexible right out of the box. It often requires little to no break-in period and is generally less expensive to manufacture.

Direct Attach (Molded Injection): The Powerhouse for Waterproofing

This modern technique involves placing the completed boot upper into a mold, which is then injected with molten rubber or polyurethane. This liquid material forms the sole and bonds chemically to the upper as it cools and hardens.

The result is a seamless, watertight bond between the upper and outsole, making it an excellent choice for consistently wet environments. The bond is also extremely strong and durable.

Understanding the Trade-offs

No single construction method is superior in all situations. Your decision depends on which trade-offs you are willing to make based on the demands of your job.

Durability vs. Flexibility

A Goodyear welt offers unmatched durability and torsional rigidity, making it ideal for heavy-duty work on uneven terrain. However, this toughness means it is stiffer and requires a significant break-in period.

Cement construction provides maximum flexibility from day one, reducing foot fatigue for workers who are constantly kneeling, crouching, or walking on flat surfaces. The trade-off is a shorter lifespan.

Repairability vs. Cost

The ability to resole a Goodyear welted boot means a higher initial cost can lead to a lower total cost of ownership over many years.

Cemented and Direct Attach boots are almost never resoleable. Once the sole wears out, the entire boot must be replaced. This makes them less expensive upfront but potentially more costly in the long run if you are hard on your footwear.

Water Resistance

While a Goodyear welt is highly water-resistant, the Direct Attach method creates a truly seamless and waterproof bond that is superior for constantly soaked conditions. The effectiveness of a cemented boot against water depends entirely on the quality of the adhesive and any additional waterproof membranes used.

Making the Right Choice for Your Job

Your daily tasks should be the final arbiter in your decision.

- If your primary focus is maximum durability and longevity in harsh environments (heavy construction, logging, ranching): Choose a Goodyear welt construction for its repairability and ruggedness.

- If your primary focus is lightweight comfort and flexibility for indoor or light-duty work (warehousing, logistics, light manufacturing): A cement construction will provide immediate comfort and reduce fatigue.

- If your primary focus is absolute waterproof protection in consistently wet conditions (plumbing, commercial fishing, agriculture): Prioritize boots with a Direct Attach construction.

Choosing the right construction is an investment in your safety, comfort, and productivity.

Summary Table:

| Construction Method | Best For | Key Strengths | Key Trade-offs |

|---|---|---|---|

| Goodyear Welt | Heavy-duty work (construction, logging) | Maximum durability, repairable, stable | Stiffer, longer break-in, higher initial cost |

| Cement Construction | Light-duty, indoor work (warehousing) | Lightweight, flexible, immediate comfort | Shorter lifespan, not typically repairable |

| Direct Attach (Molded) | Wet environments (plumbing, fishing) | Superior waterproofing, seamless bond | Not repairable, boot must be replaced |

Find Your Perfect Work Boot Match with 3515

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of work boots and shoes, including Goodyear welt, cement, and direct attach constructions, ensuring we can meet the specific demands of any trade.

Let us help you equip your workforce with boots that offer the ideal balance of safety, comfort, and longevity. Contact our expert team today to discuss your requirements and discover the 3515 advantage.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Sport Style Safety Boots for Bulk Orders

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

People Also Ask

- What makes PVC work boots a cost-effective option? Essential Protection at an Unbeatable Price

- What are the advantages of leather uppers in work boots? Unmatched Durability & Protection

- What is the purpose of heating the wax-covered boot? Achieve Deep, Lasting Waterproof Protection

- What daily maintenance steps should be taken for work boots? A Simple 3-Step Routine for Longevity

- Why is the Seamless Lining process essential in diabetic boots? Prevent Ulcers with Friction-Free Protection

- Why might someone choose PVC boots over rubber boots? Key Benefits for Budget & Weight

- How does untying laces before removing boots help in their maintenance? Protect Your Investment and Extend Boot Life

- What should electricians look for in work boots? Prioritize EH-Rated Protection for Maximum Safety