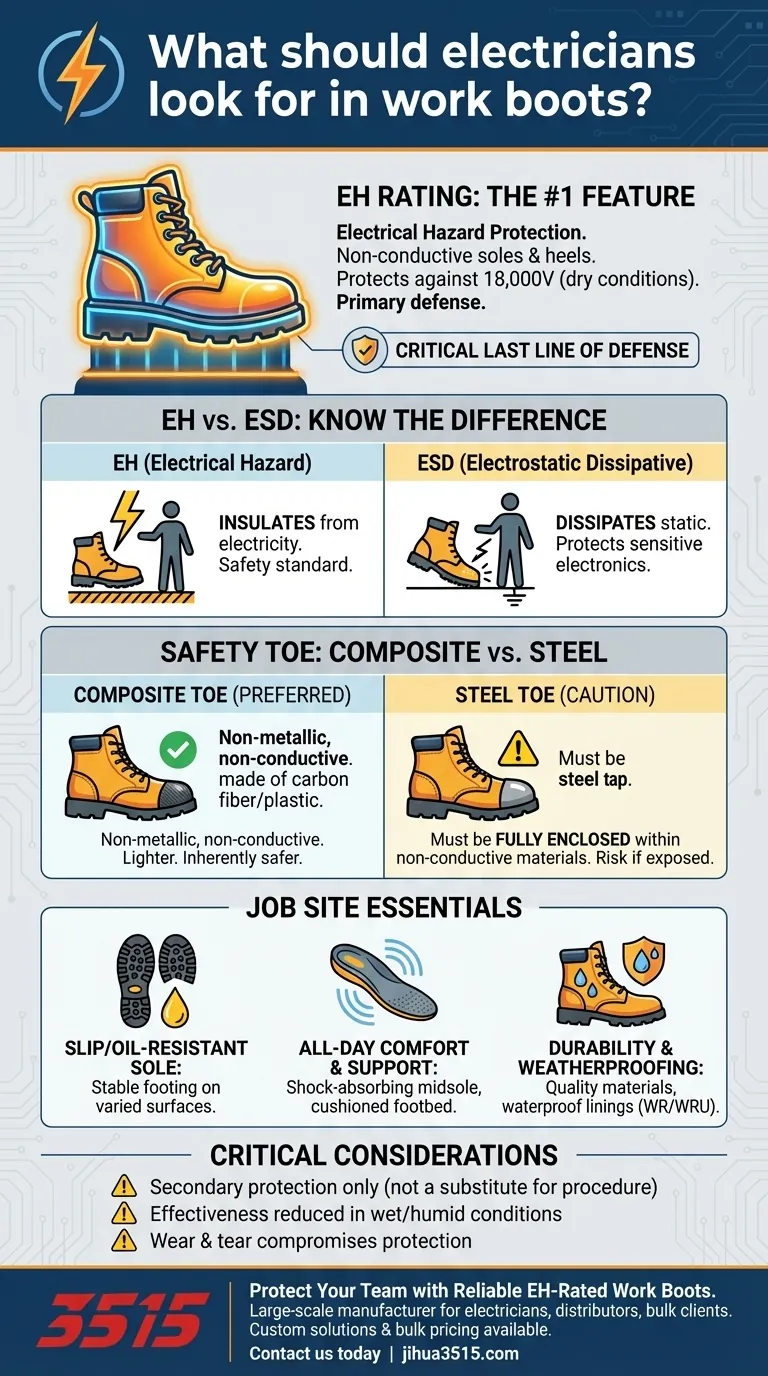

For an electrician, the single most important feature on a work boot is the EH rating. This marking signifies that the boot is designed for Electrical Hazard protection, constructed with non-conductive soles and heels. A certified EH-rated boot is tested to protect against open circuits of up to 18,000 volts under dry conditions, providing a critical last line of defense against accidental shock.

Your work boots are not just footwear; they are a critical piece of personal protective equipment (PPE). The right pair prioritizes non-conductive materials and a certified EH rating above all else, as this is your primary defense against electrical shock from the ground up.

Deconstructing Electrical Hazard (EH) Protection

Your safety hinges on understanding what the EH rating truly provides. It is more than just a label; it is a specific standard of protection built into the boot's core design.

What the EH Rating Certifies

An EH rating ensures the boot's outsole can withstand the application of 18,000 volts at 60 Hz for one minute with no current flow or leakage current in excess of 1.0 milliampere under dry conditions. This protection is designed to insulate you from the ground, preventing your body from completing an electrical circuit.

The Role of Non-Conductive Materials

This protection is achieved through materials that do not conduct electricity. The soles and heels are the most critical components, made from materials like rubber or polyurethane. The boot's construction must also ensure no conductive parts, like nails or screws, connect the sole to the upper part of the boot.

EH vs. ESD: A Critical Distinction

Do not confuse EH (Electrical Hazard) with ESD (Electrostatic Dissipative). EH boots are designed to insulate you from electricity. In contrast, ESD boots are made to dissipate static electricity buildup from your body to protect sensitive electronic equipment. For an electrician, EH is the necessary safety standard.

The Safety Toe Debate: Composite vs. Steel

While a safety toe isn't always mandated, it is highly recommended for protection against impact and compression. For electricians, the material of that toe is a crucial consideration.

Why Composite Toes Are Often Preferred

A composite toe, made from materials like carbon fiber, Kevlar, or plastic, is non-metallic and non-conductive. This makes it the inherently safer choice for an electrical environment, as it adds a layer of protection without introducing a conductive element. They are also significantly lighter.

The Risk of a Poorly Designed Steel Toe

A steel toe presents a potential risk if it becomes exposed. If the material around the steel cap wears away or the boot is poorly constructed, the exposed metal could make contact with a live circuit and conduct electricity directly through the boot.

When a Steel Toe Can Be Safe

A modern, well-constructed EH-rated boot with a steel toe is still safe for electricians. The key is that the steel cap must be fully enclosed within non-conductive materials, with no pathway for it to contact your foot or the ground.

Beyond Wires: Essential Job Site Features

While electrical protection is paramount, a good boot must also perform in the challenging and varied environments you work in every day.

Sole Performance and Traction

Job sites are unpredictable. Look for outsoles that are slip-resistant and oil-resistant to ensure stable footing on a variety of surfaces. Puncture-resistant soles can also provide critical protection from nails and other sharp debris.

All-Day Comfort and Support

Long hours on your feet require proper support. Features like a shock-absorbing midsole, a cushioned footbed, and a supportive heel are essential to prevent foot fatigue and long-term arch pain.

Durability and Weatherproofing

Your boots are an investment. High-quality leather or synthetic uppers will resist wear and tear. If you frequently work outdoors, look for waterproof linings, often indicated by a WR or WRU rating, to keep your feet dry and comfortable.

Understanding the Trade-offs and Pitfalls

Even the best EH-rated boot has limitations. Understanding these is crucial for maintaining your safety.

The Limits of EH Protection

EH protection is considered a secondary source of protection. It is not a substitute for proper safety procedures like lockout/tagout. Its effectiveness is also dramatically reduced or eliminated in wet or humid conditions.

Ignoring Wear and Tear

Your boot's EH rating is only valid if the boot is in good condition. If the sole is punctured, cracked, or worn down to the point where conductive materials are exposed, the electrical protection is compromised.

Assuming Waterproof Means Insulated

While a waterproof boot keeps your feet dry, it does not enhance electrical protection. Water that bridges over the top of your boot can create a path for electricity, completely bypassing the boot's insulated sole.

Making the Right Choice for Your Work

Selecting the right boot means matching its features to the specific demands of your job.

- If your primary focus is maximum electrical safety: Prioritize a certified EH-rated boot with a non-metallic composite toe.

- If you work in varied, slippery conditions: Ensure your EH-rated boot also has a high-traction, oil-and-slip-resistant outsole.

- If you require all-day comfort for long hours: Look for boots that combine the EH rating with excellent shock absorption and arch support.

Ultimately, your boots are a non-negotiable tool; invest in the pair that protects you without compromise.

Summary Table:

| Key Feature | Why It Matters for Electricians |

|---|---|

| EH Rating | Protects against up to 18,000 volts under dry conditions; non-conductive soles prevent electrical shock. |

| Composite Toe | Non-metallic and non-conductive, offering impact protection without electrical risk. |

| Slip/Oil-Resistant Sole | Ensures stability on unpredictable job sites. |

| Durability & Weatherproofing | Withstands wear and tear; waterproof linings keep feet dry. |

Protect Your Team with Reliable EH-Rated Work Boots

As a large-scale manufacturer, 3515 produces a comprehensive range of EH-rated footwear designed specifically for electricians, distributors, brand owners, and bulk clients. Our boots combine certified electrical hazard protection with durable construction, composite safety toes, and all-day comfort—ensuring your workforce stays safe and productive.

Contact us today to discuss custom solutions and bulk pricing for your safety needs!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- How do safety shoes contribute to cost savings for companies? A Strategic Investment in Risk and Cost Management

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What cultural and environmental considerations are tied to wearing shoes indoors? Balance Hygiene, Tradition, and Foot Health

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries