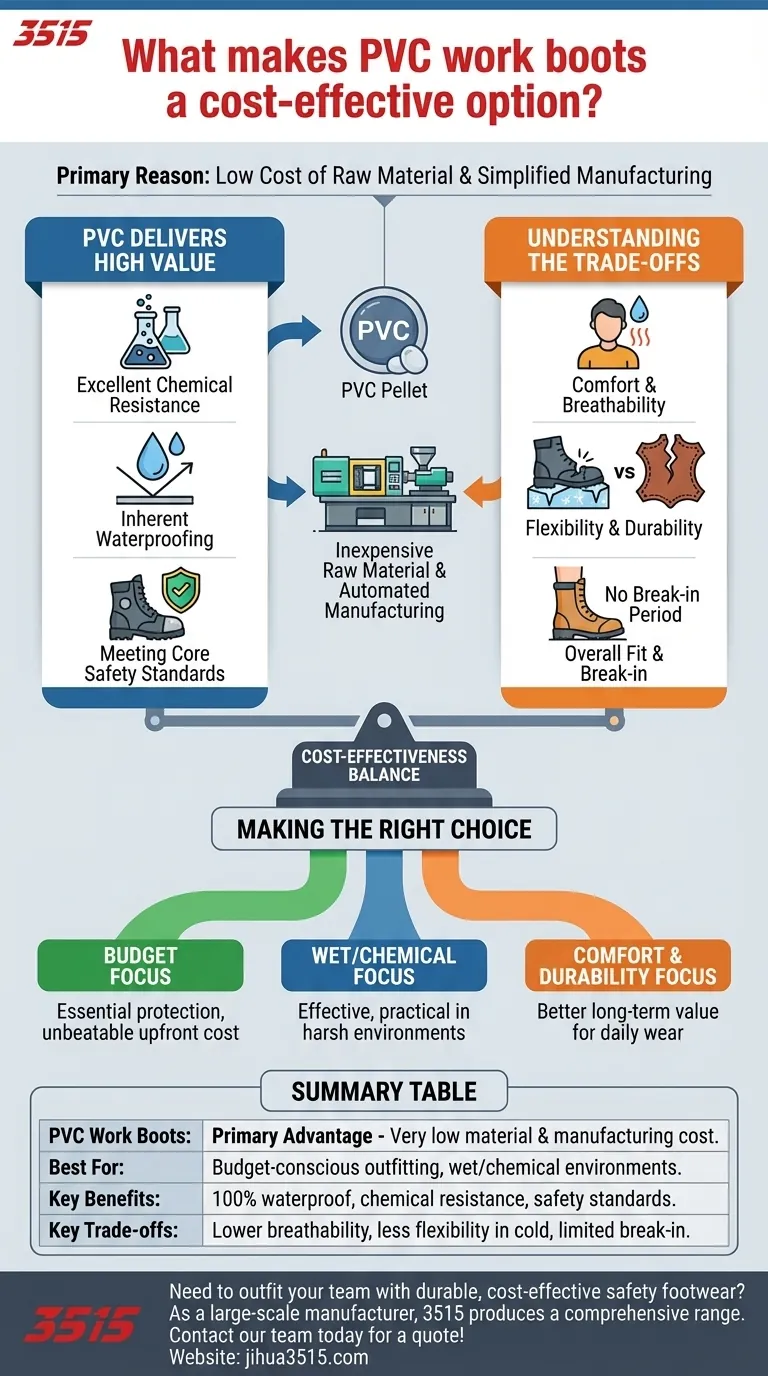

The primary reason PVC work boots are cost-effective is the low cost of the raw material itself. Polyvinyl chloride (PVC) is a synthetic plastic that is significantly cheaper to produce than natural materials like rubber or leather. This fundamental cost advantage allows manufacturers to offer essential protective features at a highly accessible price point, making them an affordable choice for outfitting large teams.

While the low material cost is the direct answer, the true measure of "cost-effectiveness" requires understanding the trade-offs. PVC provides excellent waterproof and chemical protection for its price, but this often comes at the expense of long-term comfort and durability compared to more premium materials.

What Drives PVC's Low Price Point?

The economic advantage of PVC boots stems from both the material and the manufacturing process. This combination creates a product that is affordable to produce at scale.

Inexpensive Raw Material

PVC is a widely produced synthetic polymer. Its production is a streamlined, high-volume process, making the raw material itself far less expensive than sourcing and processing natural leather or harvesting and treating natural rubber.

Simplified Manufacturing

The process of creating a PVC boot is typically based on injection molding. This automated method is faster and requires less skilled labor compared to the complex steps of crafting leather boots or vulcanizing rubber, further reducing production costs.

Where PVC Delivers High Value

Cost-effectiveness isn't just about being cheap; it's about providing adequate performance for the price. PVC excels in specific applications where its inherent properties offer significant value.

Excellent Chemical Resistance

One of PVC's standout features is its resistance to a wide range of substances, including acids, bases, fats, and oils. This makes PVC boots a highly effective and protective choice in industries like food processing, agriculture, and chemical handling.

Inherent Waterproofing

Unlike leather, which requires treatments to become water-resistant, PVC is naturally 100% waterproof. This provides reliable and complete protection from water and other liquids without any risk of the barrier degrading over time.

Meeting Core Safety Standards

Despite their low cost, PVC work boots can be equipped with all essential safety features. It is common to find them with steel toes, puncture-resistant midsoles, and slip-resistant outsoles, ensuring they meet fundamental workplace safety requirements.

Understanding the Trade-offs of PVC

The low cost of PVC comes with compromises, primarily related to user comfort and long-term durability under heavy use.

Comfort and Breathability

PVC is not a breathable material. This can lead to the buildup of sweat and heat inside the boot, causing discomfort during long shifts. While features like moisture-wicking linings can help, they cannot fully overcome the non-porous nature of the plastic.

Flexibility and Durability

Compared to rubber, PVC can become stiff and brittle in very cold temperatures, increasing the risk of cracking. Over time and with heavy use, it can also be more susceptible to cuts and abrasion than high-quality leather or specialized rubber compounds.

Overall Fit and Break-in Period

While a good fit is crucial for any boot, PVC offers very little "give" or ability to mold to the wearer's foot. There is virtually no break-in period; the initial fit is how the boot will remain, making proper sizing absolutely critical from the start.

Making the Right Choice for Your Needs

Choosing the right boot material depends entirely on balancing your budget, required protection, and daily wear conditions.

- If your primary focus is budget control for a large crew: PVC provides essential waterproof and safety-rated protection at an unbeatable upfront cost.

- If your primary focus is working in wet or chemical-heavy areas: PVC's inherent waterproof and chemical-resistant properties make it a highly effective and practical choice.

- If your primary focus is all-day comfort and long-term durability: Investing in premium rubber or leather boots will likely provide better value and foot health over the lifespan of the boot.

Ultimately, selecting the most cost-effective work boot means matching the material's strengths directly to the demands of your job.

Summary Table:

| Aspect | PVC Work Boots |

|---|---|

| Primary Advantage | Very low material and manufacturing cost |

| Best For | Budget-conscious outfitting, wet/chemical environments |

| Key Benefits | 100% waterproof, excellent chemical resistance, meets safety standards |

| Key Trade-offs | Lower breathability, less flexibility in cold, limited break-in |

Need to outfit your team with durable, cost-effective safety footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of PVC, rubber, and leather work boots for distributors, brand owners, and bulk clients. We can help you source the right protective footwear that balances cost, safety, and comfort for your specific needs.

Contact our team today for a quote and discover how our manufacturing expertise can benefit your business.

Visual Guide

Related Products

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What historical influences contributed to the development of engineer boots? From Cavalry to the Industrial Revolution

- When is it appropriate to use leather conditioner on boots? Identify the Signs of Dry Leather

- What are the main steps in maintaining waterproof leather boots? A 3-Step Guide to Lasting Protection

- What is the benefit of using a leather protecting cream on work boots? Prevent Cracking & Extend Boot Life

- How does the heel counter contribute to boot fit? The Key to Blister-Free Comfort and Stability

- What is the significance of waterproof and breathable properties in work footwear? Boost Safety in Wet Conditions

- What specific tests apply to proximity firefighting footwear? The 2 Critical Heat Tests Explained

- What is the purpose of electric hazard boots? Essential Protection for Electrical Workers