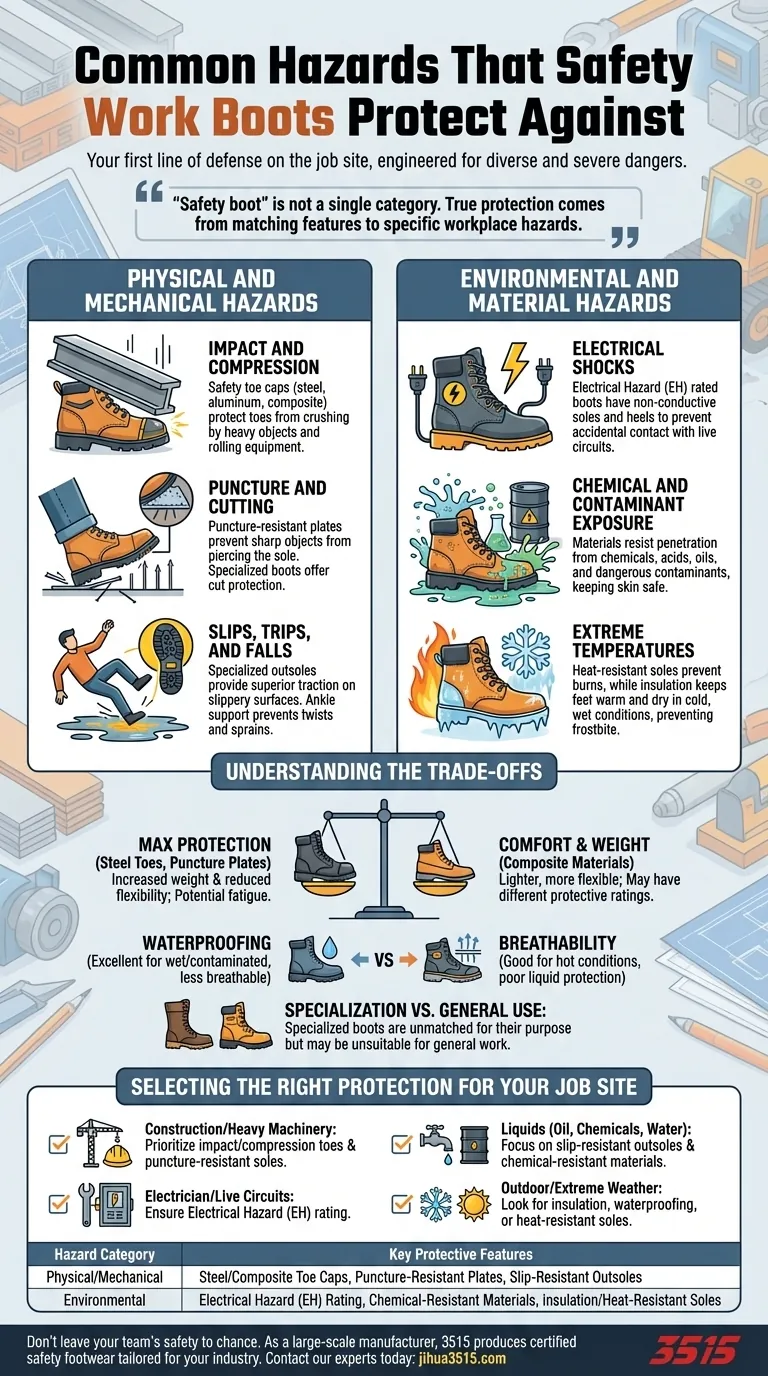

At their core, safety work boots are your first line of defense against the diverse and often severe hazards of a job site. They are engineered to protect your feet from physical impacts like falling objects, punctures from sharp materials, environmental dangers such as extreme temperatures, and exposure to harmful substances like chemicals and electrical currents.

The most critical takeaway is that "safety boot" is not a single category. True protection comes from matching the specific protective features of the boot—such as steel toes, puncture plates, or chemical-resistant materials—to the precise hazards present in your specific work environment.

Physical and Mechanical Hazards

The most intuitive function of a safety boot is to guard against direct physical harm. These hazards involve kinetic force, sharp objects, and the simple-but-common danger of losing your footing.

Impact and Compression

The most well-known feature is the safety toe cap, typically made of steel, aluminum, or composite materials. This reinforcement protects your toes from being crushed by heavy falling objects or compressed by rolling equipment, such as a forklift or pallet jack.

Puncture and Cutting

Job sites are often littered with sharp objects like nails, screws, and metal scraps. Puncture-resistant plates are integrated into the midsole to prevent these items from piercing the sole and injuring your foot. Specialized boots also offer protection from cutting tools like chainsaws.

Slips, Trips, and Falls

Slips and falls are among the most common workplace injuries. Safety boots feature specialized outsoles designed to provide superior traction on slippery or uneven surfaces, including those contaminated with water, oil, or chemicals. The ankle support in high-cut boots also helps prevent twists and sprains on rough terrain.

Environmental and Material Hazards

Beyond direct physical force, your work environment can present a range of thermal, chemical, and electrical threats that require specialized footwear.

Electrical Shocks

For anyone working near live electricity, Electrical Hazard (EH) rated boots are essential. They are constructed with non-conductive materials in the sole and heel to provide a secondary source of protection against accidental contact with live electrical circuits.

Chemical and Contaminant Exposure

Many industries, from oil fields to manufacturing, involve exposure to corrosive or harmful substances. Boots designed for these environments use materials that resist penetration from chemicals, acids, oils, and other dangerous contaminants, keeping your skin safe.

Extreme Temperatures

Safety boots can protect against both heat and cold. Some are designed with heat-resistant soles to prevent burns from hot surfaces, while others feature insulation to keep feet warm and dry in extreme cold and wet conditions, preventing frostbite and maintaining comfort.

Understanding the Trade-offs

Selecting the right boot involves balancing competing needs, as a feature that excels in one area may be a liability in another. There is no single "best" boot for every hazard.

Protection vs. Comfort and Weight

Heavily reinforced boots with steel toes and puncture plates offer maximum protection against physical hazards. However, this often comes at the cost of increased weight and reduced flexibility, which can lead to fatigue over a long workday. Lighter composite materials are an alternative but may have different protective ratings.

Waterproofing vs. Breathability

A fully waterproof and chemical-resistant boot is excellent for wet or contaminated environments. The trade-off is often a lack of breathability, which can lead to discomfort and sweating in hot conditions. Conversely, a highly breathable boot may offer poor protection against liquids.

Specialization vs. General Use

A boot designed for a specific hazard, like a logger's boot for chainsaw protection, is unmatched for its intended purpose. However, its specialized features may make it unsuitable or uncomfortable for general construction work. Always prioritize the primary hazards of your specific role.

Selecting the Right Protection for Your Job Site

To make an informed choice, you must first assess your environment and then match the boot's certified features to the hazards you face daily.

- If you work in construction or with heavy machinery: Prioritize boots with certified impact/compression-rated safety toes and puncture-resistant soles.

- If you are an electrician or work near live circuits: Ensure your boots have a clear Electrical Hazard (EH) rating to protect against shock.

- If your environment involves liquids like oil, chemicals, or water: Focus on boots with highly slip-resistant outsoles and materials proven to resist chemical penetration.

- If you work outdoors in extreme weather: Look for features like insulation for cold, waterproofing for rain, and soles rated for high heat if applicable.

Choosing the right safety boot is an essential investment in your personal safety and daily productivity.

Summary Table:

| Hazard Category | Key Protective Features |

|---|---|

| Physical/Mechanical | Steel/Composite Toe Caps, Puncture-Resistant Plates, Slip-Resistant Outsoles |

| Environmental | Electrical Hazard (EH) Rating, Chemical-Resistant Materials, Insulation/Heat-Resistant Soles |

Don't leave your team's safety to chance. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear tailored for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes designed to meet the specific hazards of your industry—from construction and electrical work to chemical handling and extreme weather.

Contact our experts today to discuss your specific needs and discover how our reliable, high-quality safety footwear can protect your workforce and enhance productivity.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Durable Goodyear Welt Leather Work Boots for Wholesale & Private Label

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- What are five style inspirations for wearing moc toe boots? Elevate Your Style with Timeless Versatility

- How should work boot laces be maintained? Ensure Safety and Extend Boot Life

- Can work boots be cleaned in a washing machine? Avoid Damage and Extend Boot Life

- Why use metal mesh racks for boot disinfection? Essential Tips for Complete Hydrogen Peroxide Sterilization

- Why are PVC work boots lightweight? Unibody Design & Low-Density Material Explained

- How do insulated boots help with moisture control? Keep Your Feet Warm and Dry

- How does nanotechnology improve composite toe work boots? Achieve Lighter, More Comfortable Protection

- What are the benefits of heavy-duty or cruising boots for long-distance driving? Maximize Safety & Reduce Fatigue