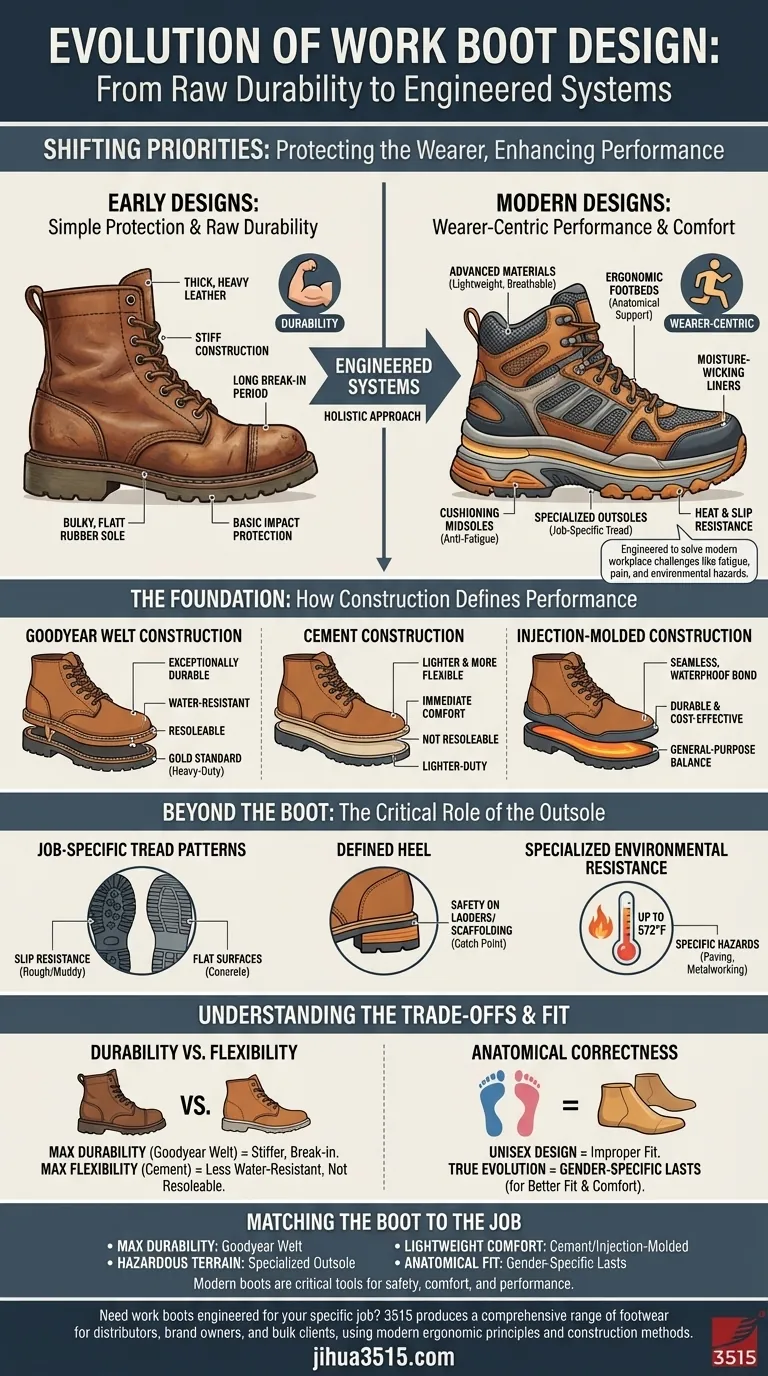

The evolution of the work boot is a story of shifting priorities, moving from basic protection to a sophisticated blend of safety, all-day comfort, and job-specific performance. Early boots were defined by their raw durability, typically using thick leather. Today's designs are engineered systems incorporating advanced materials, ergonomic principles, and specialized construction to solve modern workplace challenges like fatigue, pain, and environmental hazards.

The core evolution in work boot design is the shift from a singular focus on durability to a holistic approach centered on the wearer. Modern boots are now engineered to enhance performance and protect long-term health, not just to shield the foot from immediate impact.

From Raw Durability to Engineered Systems

The fundamental purpose of a work boot has expanded significantly. What was once a simple piece of protective gear is now a complex tool designed for the human body.

The Era of Simple Protection

Early work boots had one primary job: to be tough. They were constructed from heavy leather and built to withstand abuse, with little consideration for the person wearing them.

This singular focus on durability often meant the boots were heavy, stiff, and required a significant "break-in" period, contributing to foot fatigue and discomfort.

The Modern Focus on the Wearer

Contemporary boot design starts with the user. Innovations in materials and ergonomics are now standard, directly addressing issues that were once accepted as part of the job.

Cushioning midsoles, anatomical footbeds, and moisture-wicking liners combat foot pain and sweat. This blend of traditional craftsmanship with modern technology creates a boot that supports the worker throughout the day, improving both safety and productivity.

The Foundation: How Construction Defines Performance

The method used to attach the sole of a boot to its upper part is a critical design choice that dictates its flexibility, durability, and cost.

Goodyear Welt Construction

This traditional method involves stitching the upper to a strip of leather (the "welt"), which is then stitched to the sole.

Goodyear welting creates an exceptionally durable, water-resistant, and resoleable boot. It is often considered the gold standard for heavy-duty work footwear.

Cement Construction

In this method, the outsole is attached to the upper using a strong adhesive.

This results in a boot that is significantly lighter and more flexible right out of the box. Cement construction is common in lighter-duty boots where comfort and agility are prioritized over maximum longevity.

Injection-Molded Construction

This process involves fusing the sole directly to the upper by injecting molten material into a mold.

This creates a seamless, waterproof bond that is both durable and cost-effective. Injection-molded boots offer a strong balance of features for general-purpose work.

Beyond the Boot: The Critical Role of the Outsole

The evolution of design is highly visible on the bottom of the boot, where specialization for different environments is key.

Job-Specific Tread Patterns

The outsole's tread is no longer a generic pattern. Deeper, more aggressive treads are designed for slip resistance on rough or muddy surfaces.

Conversely, shallower patterns are better suited for flat surfaces like concrete floors, offering more surface contact and stability.

The Importance of a Defined Heel

For workers who frequently use ladders or climb on scaffolding, a defined heel is a crucial safety feature. It provides a catch point on rungs, significantly reducing the risk of a slip.

Specialized Environmental Resistance

Modern outsoles are often formulated for specific hazards. For industries like road paving or metalworking, heat resistance is vital.

High-performance outsoles can be rated to withstand contact with surfaces as hot as 572ºF, preventing degradation and protecting the wearer.

Understanding the Trade-offs

Choosing the right work boot involves understanding that every design feature comes with a corresponding compromise.

Durability vs. Flexibility

The most durable construction method, the Goodyear welt, often results in a stiffer, heavier boot that requires a break-in period.

Conversely, the more flexible and comfortable cement construction is not as water-resistant and typically cannot be resoled, limiting the boot's total lifespan.

The Pitfall of Unisex Design

A critical but often overlooked aspect of modern design is anatomical correctness. Many manufacturers still use the same foot form, or 'last,' for both men's and women's boots.

This "unisex" approach fails to account for key anatomical differences, leading to improper fit and discomfort for female workers. A truly evolved design uses gender-specific lasts.

Matching the Boot to the Job

Your choice should be dictated by the specific demands of your work environment and your personal need for comfort.

- If your primary focus is maximum durability and repairability: Look for Goodyear welt construction, which allows for multiple resoles and can withstand the harshest conditions.

- If your primary focus is lightweight comfort for long hours on your feet: Cement or injection-molded construction will likely provide better immediate flexibility and reduce fatigue.

- If your primary focus is safety on varied or hazardous terrain: Pay close attention to the outsole's tread depth, heel definition, and any specific heat or slip resistance ratings.

- If you require an anatomically correct fit: Seek out brands that explicitly design and build their women's boots on a dedicated women's last.

Ultimately, the modern work boot is no longer just equipment; it's a critical tool engineered for your safety, comfort, and performance.

Summary Table:

| Era | Primary Focus | Key Features |

|---|---|---|

| Early Designs | Raw Durability | Heavy leather, stiff construction, long break-in period |

| Modern Designs | Wearer-Centric Performance | Advanced materials, ergonomic footbeds, specialized outsoles |

Need work boots engineered for your specific job?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes, designed with modern ergonomic principles, specialized construction methods (like Goodyear welt and cement), and job-specific outsoles to enhance worker safety, comfort, and productivity.

Contact us today to discuss your requirements and discover how our boots can be a critical tool for your team's performance.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Sport Style Safety Boots for Bulk Orders

- Heavy Duty Nubuck Safety Boots Safety Shoes for Global Distribution

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- What are the characteristics of synthetic/leather boots? Modern Performance Meets Lightweight Durability

- What are the requirements for impact resistance in safety toe boots? Ensure Maximum Protection for Your Workforce

- What are the signs that work boots need replacement? Protect Your Feet and Safety on the Job

- What are the key characteristics of farm boots? Essential Features for Durability & Safety

- What should you check when shopping for non-conductive work boots? Verify the EH Rating for Maximum Safety

- What are work boots for women? Engineered for Safety, Fit, and Performance

- Why do wildland fire boots have high heels? A Guide to Stability vs. Mobility

- What are some modern variations of engineer boots? A Guide to Contemporary Styles & Materials