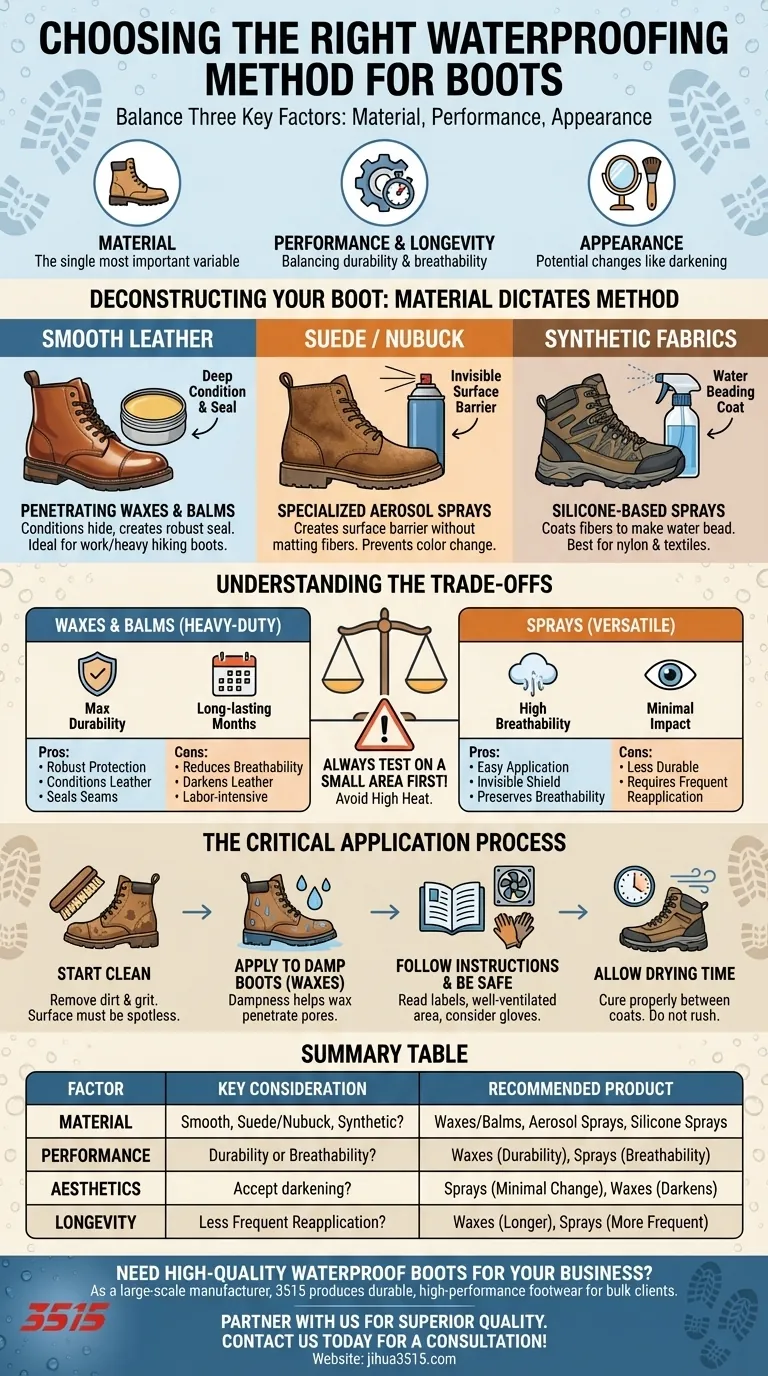

Choosing the right waterproofing method for your boots requires balancing three key factors: the boot's material, the level of performance and longevity you need, and the potential impact on the boot's appearance. The material, whether it's smooth leather, suede, or a synthetic fabric, is the single most important variable that will dictate which products are suitable.

The most effective waterproofing strategy isn't just about applying a product; it's a holistic approach that considers your boot's original construction, its material, and your intended use to create a durable and reliable barrier against moisture.

Deconstructing Your Boot: The Foundation of Protection

Before selecting a product, you must first understand the asset you are trying to protect. The specific materials and construction methods of your boot create the baseline for its water resistance.

Material Dictates the Method

The surface of your boot is the first line of defense. Different materials require fundamentally different treatments to avoid damage and ensure effectiveness.

- Smooth Leather: This material benefits most from penetrating waxes and balms that condition the hide while creating a robust waterproof seal.

- Suede or Nubuck: These textured leathers are sensitive and can be ruined by heavy waxes. They require specialized aerosol sprays that create a surface barrier without matting the fibers or drastically changing the color.

- Synthetic Fabrics: Nylon and other textiles are non-porous and best treated with silicone-based sprays that coat the fibers to make water bead and roll off.

Construction and Seams

Water's primary entry points are often not the material itself, but the seams and points of attachment.

Look closely at how the sole is attached. Sewn soles (like a Goodyear welt) have stitching that can wick moisture, making it critical to seal these threads thoroughly. Direct-attached soles must have a perfect waterproof seal at the bond to be effective.

Built-in Waterproof Liners

Many modern boots come with a waterproof, breathable membrane (like Gore-Tex) built in. While this liner is your primary defense, applying an exterior treatment is still crucial. It prevents the outer material from becoming saturated, which maintains breathability and reduces the boot's drying time.

Choosing Your Waterproofing Agent

With a clear understanding of your boot, you can now select the appropriate agent. The choice generally comes down to waxes, which penetrate and condition, or sprays, which create a surface barrier.

Waxes and Balms: The Heavy-Duty Choice

These products are ideal for smooth leather work boots or heavy-duty hiking boots. They are worked into the leather, deeply conditioning it and creating a highly durable, long-lasting barrier. They are particularly effective at sealing vulnerable seams and welting.

Sprays: The Versatile Protector

Waterproofing sprays are the go-to solution for delicate materials like suede and nubuck, as well as synthetic fabrics. They are easy to apply and create an invisible shield that repels water while having minimal impact on the material's appearance and breathability.

Understanding the Trade-offs

No waterproofing method is perfect. You must weigh the pros and cons based on your specific needs.

Performance vs. Breathability

There is often a direct trade-off between the level of water resistance and the material's ability to breathe. Heavy waxes offer the most robust protection but can reduce breathability, potentially leading to clammy feet during high-exertion activities. Sprays typically preserve breathability more effectively.

Aesthetics and Material Integrity

Always assume a waterproofing product might alter your boot's appearance. Waxes and oils will almost certainly darken smooth leather. This is why you must test any product on a small, inconspicuous area first. Furthermore, never use high heat like a hairdryer to speed up drying, as it can damage leather permanently.

Longevity vs. Reapplication

Wax treatments are more labor-intensive to apply but can last for many months of hard use. Sprays are fast and easy to apply but will need to be reapplied more frequently, especially if the boots see regular exposure to moisture and abrasion.

The Critical Application Process

How you apply the treatment is just as important as which one you choose.

Start with a Clean Surface

Applying a waterproofing product to a dirty boot is ineffective. Dirt and grit create a barrier that prevents the treatment from penetrating or adhering properly, leaving gaps in your protection.

Apply to Damp Boots

For leather treatments like waxes, it is often best to apply them to clean but slightly damp boots. The moisture already present within the leather's pores helps draw the waterproofing agent deeper into the material for a more thorough seal.

Follow Instructions and Be Safe

Always read and follow the product's specific instructions. When using sprays or chemicals, work in a well-ventilated area and consider wearing gloves. Allow adequate drying time between coats to ensure a proper cure.

Making the Right Choice for Your Boots

Your decision should be guided by the type of boot you have and how you plan to use it.

- If your primary focus is maximum durability for leather work or hiking boots: A wax-based treatment offers the best combination of water resistance and leather conditioning.

- If your primary focus is preserving the look of casual suede or nubuck boots: A specialized aerosol spray designed for that material is the only correct choice.

- If your primary focus is quick protection for synthetic fabric footwear: A silicone-based spray provides effective and easy-to-apply water repellency.

Ultimately, waterproofing is an essential maintenance step that protects your investment and ensures your feet stay dry and comfortable.

Summary Table:

| Factor | Key Consideration | Recommended Product Type |

|---|---|---|

| Material | Smooth leather, suede/nubuck, or synthetic fabric? | Waxes/Balms, Aerosol Sprays, Silicone Sprays |

| Performance | Maximum durability or breathability? | Waxes for durability, Sprays for breathability |

| Aesthetics | Willing to accept darkening? | Sprays for minimal change, Waxes darken leather |

| Longevity | Less frequent reapplication? | Waxes last longer, Sprays need more frequent use |

Need High-Quality Waterproof Boots for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable, high-performance waterproof footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of boots, from rugged leather work boots to stylish suede and synthetic options, all designed with optimal waterproofing in mind.

Partner with us to offer your customers superior quality and reliability. Let's discuss how we can meet your specific needs and help you build a stronger product line.

Contact our team today for a consultation!

Visual Guide

Related Products

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

People Also Ask

- How does the slip resistance of industrial safety shoes protect workers during Genset maintenance? Prevent Oil Slips

- Why is it necessary to equip operators with professional safety shoes in a flour milling workshop? Prevent Slip Hazards

- What specific protective features are required for safety shoes in high-temperature rotary kiln maintenance areas?

- What protective functions do industrial safety shoes provide for utility technicians? Stability & Electrical Insulation

- What do the symbols on safety footwear indicate? A Guide to Decoding Boot Safety Ratings