At a minimum, all safety shoes must have a reinforced safety toe cap that protects against impact and compression, along with a slip-resistant outsole. Essential features often include a durable leather or synthetic upper, oil resistance, and a certified impact and compression rating, typically designated as "75" in the US standard.

The most critical factor in choosing a safety shoe isn't finding one with the most features, but selecting one with the right features that directly address the specific hazards of your work environment.

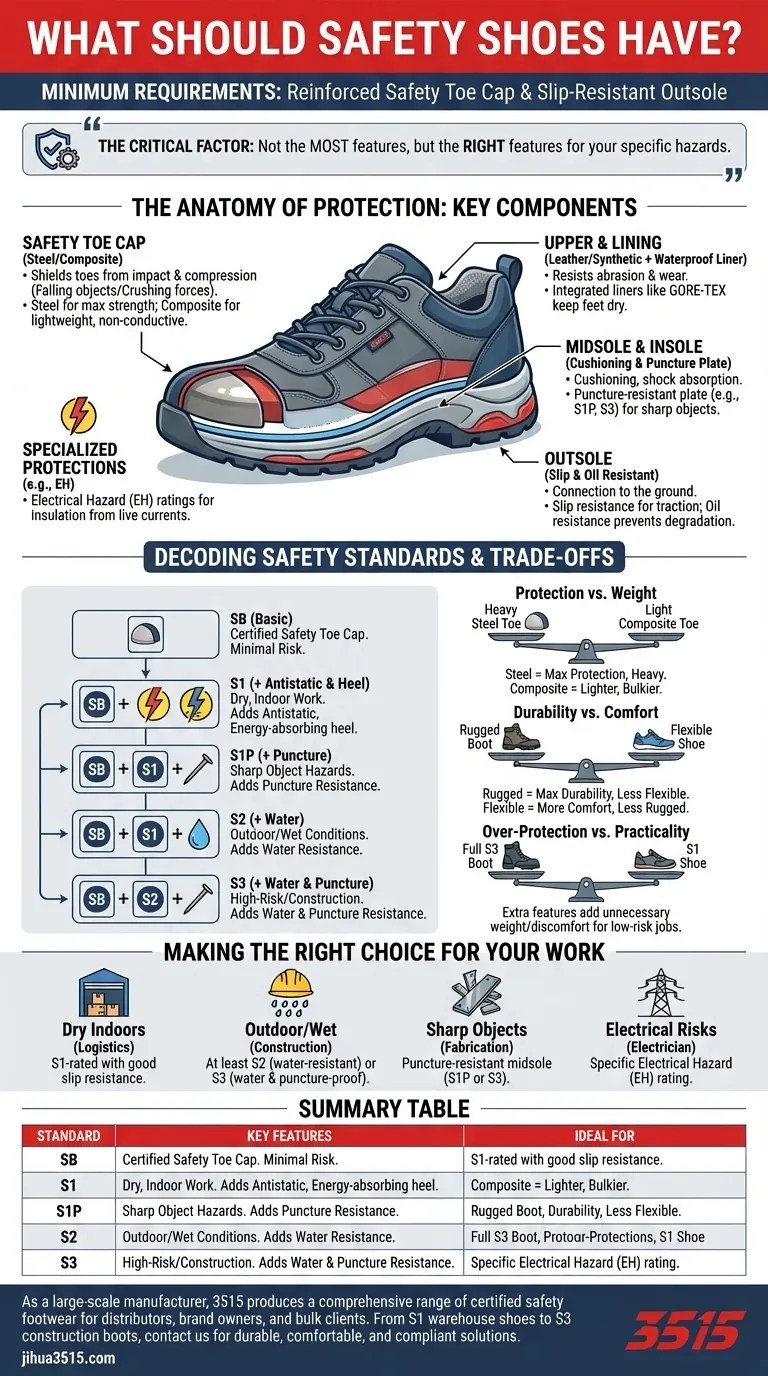

The Anatomy of Protection: Key Components

Understanding what makes up a safety shoe helps you evaluate its protective qualities. Each part serves a distinct purpose, and high-quality materials are essential for them to work together effectively.

The Safety Toe Cap

This is the most fundamental feature. Its sole purpose is to shield your toes from falling objects (impact) and crushing forces (compression).

The most common materials are steel, known for maximum strength, and composite materials like thermoplastics or aluminum, which are lighter and don't conduct heat or cold.

The Outsole

The outsole is your connection to the ground. Its primary job is providing slip resistance to maintain traction on wet, oily, or uneven surfaces.

Many outsoles are also designed for oil resistance to prevent the material from degrading when exposed to petrochemicals.

The Upper and Lining

The upper is the main body of the shoe that covers your foot. It's typically made of leather or durable synthetic materials that resist abrasion and wear.

For wet environments, an integrated waterproof liner, such as GORE-TEX, is a crucial feature to keep your feet dry and comfortable.

The Midsole and Insole

The midsole provides cushioning and shock absorption, while the insole offers direct underfoot comfort.

In some safety shoes, the midsole also contains a puncture-resistant plate to protect you from stepping on sharp objects like nails.

Specialized Protections

Beyond the core components, many shoes offer protection against specific risks, such as Electrical Hazard (EH) ratings, which insulate you from live electrical currents.

Decoding the Safety Standards

To simplify selection, safety shoes are often certified under a classification system. These codes bundle protections together, making it easier to match a shoe to a job's requirements.

The Basic Standard (SB)

This is the most basic level of protection. An SB-rated shoe only guarantees that it has a certified safety toe cap. The heel area of the shoe may even be open.

The S1 Standard

An S1 shoe includes the safety toecap plus protection against static electricity (antistatic) and an energy-absorbing heel to reduce impact on your body. These are ideal for dry, indoor work environments.

Higher-Level Protections (S1P, S2, S3+)

As the numbers increase, so do the protective features.

- S1P adds puncture resistance to the S1 standard.

- S2 adds water resistance to the S1 standard.

- S3 combines them all: it is an S1 shoe with added puncture resistance and water resistance.

Understanding the Trade-offs

No single safety shoe is perfect for every situation. Choosing the right one means balancing competing factors.

Protection vs. Weight

Steel toes offer exceptional protection but add significant weight and conduct temperature. Composite toes are much lighter but may result in a slightly bulkier toe box to achieve the same safety rating.

Durability vs. Comfort

A highly rugged and rigid boot built for the harshest environments may offer maximum durability, but it will be less comfortable and flexible for a job that requires constant walking or kneeling.

Over-Protection vs. Practicality

Buying an S3-rated, fully waterproof, puncture-resistant boot for a dry warehouse job is unnecessary. The extra features add weight and reduce breathability, leading to discomfort without providing any relevant safety benefit for that environment.

Making the Right Choice for Your Work

Your specific job hazards should be the ultimate guide for your decision.

- If you work primarily indoors in dry areas (e.g., logistics, assembly): An S1-rated shoe with a good slip-resistant sole is an excellent choice.

- If your work involves outdoor or wet conditions (e.g., construction, landscaping): You need at least an S2 (water-resistant) or S3 (water-resistant and puncture-proof) rating.

- If you face risks from sharp objects on the ground (e.g., demolition, metal fabrication): A puncture-resistant midsole is non-negotiable, found in S1P and S3 ratings.

- If you are an electrician or work near live circuits: You must select a shoe with a specific Electrical Hazard (EH) rating to ensure proper insulation.

Choosing the right safety shoe is a critical investment in your personal safety; always match the protection to the specific risks you face every day.

Summary Table:

| Safety Standard | Key Features | Ideal For |

|---|---|---|

| SB | Basic safety toe cap | Minimal risk environments |

| S1 | Toe cap, antistatic, energy-absorbing heel | Dry, indoor work (logistics, assembly) |

| S1P | S1 features + puncture resistance | Sharp object hazards (metal fabrication) |

| S2 | S1 features + water resistance | Outdoor/wet conditions |

| S3 | S2 features + puncture resistance | Construction, landscaping, high-risk environments |

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Whether you need S1-rated shoes for warehouse teams or S3-rated boots for construction crews, our production capabilities ensure durable, comfortable, and fully compliant protection for any work environment. Contact us today to discuss your specific safety requirements and receive a customized quote for your workforce.

Visual Guide

Related Products

- Premium KPU Athletic Safety Shoes for Wholesale

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Wholesale Leather Safety Boots with Customizable Protective Toe

- Wholesale Durable Breathable Safety Boots Custom OEM Manufacturer

People Also Ask

- Why is expert help recommended when selecting safety shoes? Ensure Perfect Fit & Hazard Protection

- What are the conditions faced by employees in meatpacking and poultry slaughter plants? Navigating Pervasive Slip Hazards

- What do the markings on ASTM-compliant safety shoes indicate? Decode the Safety Labels for Maximum Protection

- What materials are used in the construction of these boots? A Guide to Velour Leather, Textile & PU Soles

- What does a green triangle symbol on safety footwear mean? Your Guide to Maximum Puncture & Impact Protection