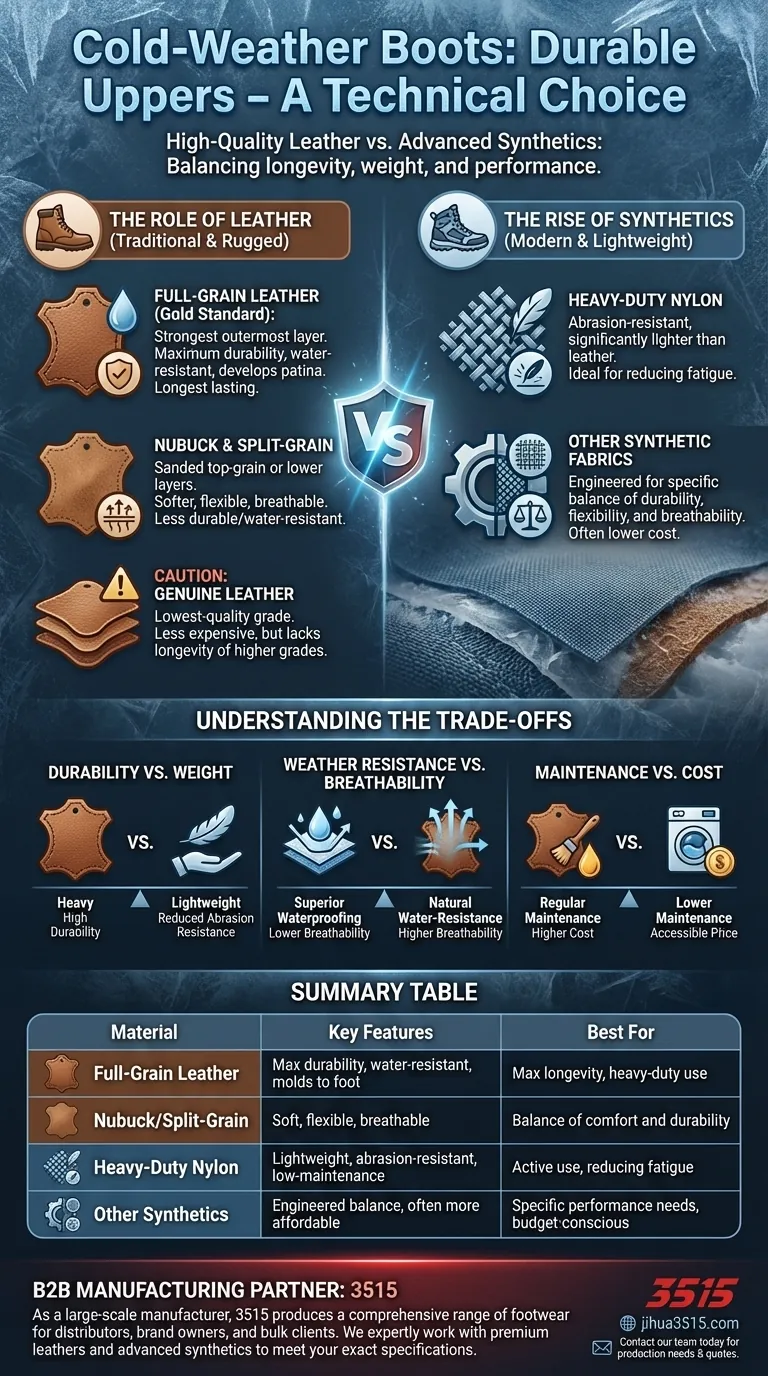

When selecting cold-weather boots, the most durable and common materials for the uppers are high-quality leathers and advanced synthetic fabrics. The choice between them is not simply a matter of preference; it's a technical decision based on the specific balance of durability, weight, and weather resistance you require.

The core decision isn't just choosing between leather and synthetics, but understanding that the specific type of each material dictates the boot's ultimate performance. Full-grain leather offers maximum longevity, while specialized nylons provide a lightweight, low-maintenance alternative.

The Role of Leather in Cold-Weather Boots

Leather has been the traditional material for rugged footwear for centuries, prized for its ability to mold to the foot and withstand significant abuse. However, not all leather is created equal.

Full-Grain Leather: The Gold Standard

Full-grain leather is made from the strongest, outermost layer of the animal hide. This material is the most durable and water-resistant type of leather available. Over time, it develops a unique patina rather than wearing out, making it the top choice for boots intended to last for many years.

Nubuck and Split-Grain Leather

Nubuck leather is a type of top-grain leather that has been sanded to create a soft, suede-like finish. Split-grain leather, taken from the lower layers of the hide, is often used to create suede. Both are more flexible and breathable than full-grain leather but offer less durability and water resistance.

Genuine Leather: A Note of Caution

While the term sounds premium, "genuine leather" typically refers to one of the lowest-quality grades. It is made from the layers of the hide that remain after the top layers are split off. Boots made from genuine leather are less expensive but will not offer the durability or longevity of higher-grade options.

The Rise of Synthetic Materials

Modern synthetic materials offer a compelling alternative to leather, often engineered for specific performance characteristics like reduced weight and superior waterproofing.

Heavy-Duty Nylon

Fabrics like heavy-duty nylon are frequently used in boot uppers, especially in hybrid designs. Nylon provides excellent abrasion resistance and is significantly lighter than leather. This makes it ideal for reducing fatigue during long treks in the snow.

Other Synthetic Fabrics

Many brands also utilize proprietary synthetic textiles. These materials are engineered to provide a specific balance of durability, flexibility, and breathability, often at a lower cost and weight than high-end leather.

Understanding the Trade-offs

Choosing the right material requires acknowledging the inherent compromises between different performance metrics.

Durability vs. Weight

Full-grain leather is the undisputed champion of long-term durability but is also the heaviest option. Synthetics offer a much lighter boot but may not withstand the same level of chronic abrasion and wear over a decade of use.

Weather Resistance vs. Breathability

Well-maintained leather is naturally water-resistant and breathable. Synthetics, especially when paired with a waterproof membrane, can offer superior protection from moisture but may sacrifice some breathability, potentially leading to dampness from sweat.

Maintenance and Cost

Leather requires regular cleaning and conditioning to maintain its protective properties and prevent it from drying out and cracking. Synthetic boots are generally lower maintenance and often come at a more accessible price point.

Making the Right Choice for Your Needs

Your ideal boot material depends entirely on your primary use case and priorities.

- If your primary focus is maximum durability and longevity: Seek out boots constructed with full-grain leather uppers.

- If your primary focus is a lightweight feel for active use: Prioritize boots that feature heavy-duty nylon or other synthetic fabrics.

- If your primary focus is a balance of durability and flexibility: Consider a hybrid design that uses leather in high-wear areas and synthetic panels for reduced weight.

Understanding these core materials empowers you to look beyond marketing and select a boot truly engineered for your specific winter demands.

Summary Table:

| Material | Key Features | Best For |

|---|---|---|

| Full-Grain Leather | Maximum durability, water-resistant, molds to foot | Maximum longevity, heavy-duty use |

| Nubuck/Split-Grain | Soft, flexible, breathable | Balance of comfort and durability |

| Heavy-Duty Nylon | Lightweight, abrasion-resistant, low-maintenance | Active use, reducing fatigue |

| Other Synthetics | Engineered balance, often more affordable | Specific performance needs, budget-conscious |

Need high-volume, durable cold-weather boots for your customers?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. We expertly work with both premium leathers and advanced synthetics to create boots that meet your exact specifications for durability, weight, and performance.

Contact our team today to discuss your production needs and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Rubber Sole Outdoor Shoes Wholesale & Custom Manufacturing

- Premium Insulated Safety Boots and Shoes for Wholesale & Bulk Orders

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Durable Waterproof Rain Boots | Custom Manufacturer for Wholesale & Brands

People Also Ask

- How often should military boots be maintained? A Proactive Guide to Maximize Boot Lifespan

- Why is ankle support important in motorcycle boots? Prevent Catastrophic Injuries in a Crash

- Are desert boots appropriate for office wear? A Guide to Smart-Casual Style

- Why are jump boots less suitable for everyday wear? Understand the Specialist vs. Generalist Design

- What is the function of the steel shank in jungle boots? Unlock Maximum Support & Protection

- How does comfort contribute to the performance of military boots? The Key to Soldier Endurance and Mission Success

- How is Cordura used in military and outdoor gear? For Unmatched Durability & Reliability

- What are the benefits of maintaining military boots? Ensure Mission Readiness and Maximize Lifespan