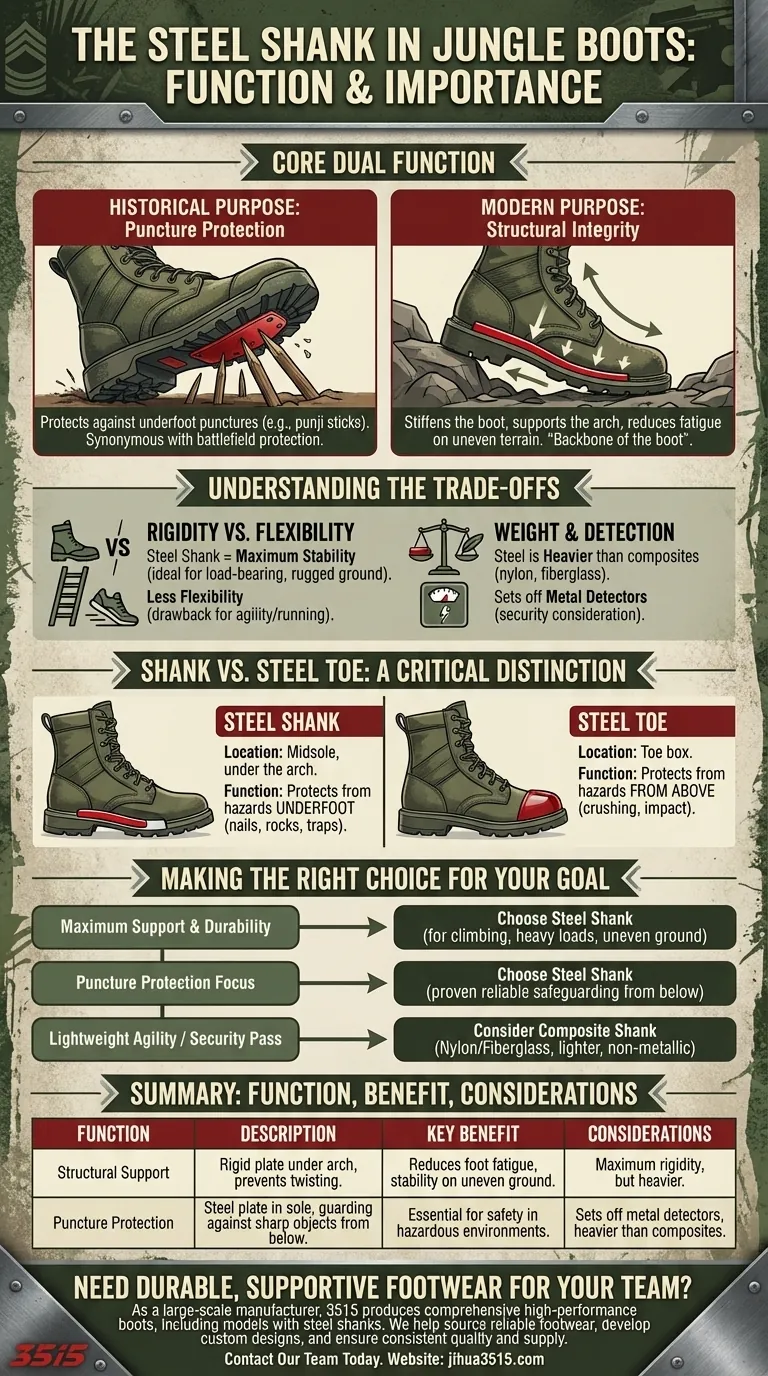

At its core, the steel shank in a jungle boot serves a dual function rooted in both historical necessity and fundamental biomechanics. It acts as a protective plate against underfoot punctures while also providing critical structural support to the arch of the foot, reducing fatigue on uneven terrain.

While famously known for protecting soldiers from punji stick traps, the steel shank's more universal and enduring function is to provide the rigidity and stability required for navigating challenging environments.

The Dual Role of the Steel Shank

The function of a steel shank is best understood by looking at its two main purposes: puncture protection and structural support. One is a specific, historical application, while the other is a core principle of quality boot design.

Historical Purpose: Puncture Protection

The original military specification for jungle boots during the Vietnam War included a steel plate in the sole.

Its primary purpose was to protect the wearer's foot from being impaled by sharpened "punji sticks" hidden as booby traps. This feature made the shank synonymous with battlefield protection.

Modern Purpose: Structural Integrity

Beyond puncture resistance, the shank is the backbone of the boot. It is a stiff strip of metal positioned between the insole and outsole, directly under the arch.

This rigidity prevents the boot from flexing or torsioning in the middle. By distributing weight more evenly across the foot, it provides essential arch support and drastically reduces foot fatigue when climbing ladders, hiking on rocky ground, or carrying heavy loads.

Understanding the Trade-offs

While effective, a steel shank is not the only option, and it comes with specific trade-offs compared to modern alternatives.

Rigidity vs. Flexibility

A steel shank provides maximum stability and support, which is ideal for load-bearing and rugged terrain.

However, this rigidity can make the boot feel less flexible, which may be a drawback for activities requiring more agility or "ground feel," such as running.

Weight and Detection

Steel is heavier than modern composite materials like nylon or fiberglass, which can also be used for shanks.

Additionally, a steel shank will reliably set off metal detectors, a practical consideration for those working in secure facilities or traveling frequently.

Shank vs. Steel Toe: A Critical Distinction

It is common to confuse a steel shank with a steel toe, but they serve entirely different protective functions.

Location and Function

A steel shank is a narrow plate located in the midsole, supporting the arch of the foot from underneath.

A steel toe, conversely, is a reinforced cap placed in the toe box of the boot. Its sole purpose is to shield the toes from crushing or impact injuries from falling or rolling objects.

Hazard Protection

The shank protects you from hazards underfoot, like nails, sharp rocks, or historical traps.

The steel toe protects you from hazards from above or in front, like a dropped tool or a heavy piece of equipment. A boot can have one, the other, or both.

Making the Right Choice for Your Goal

Understanding the role of the steel shank allows you to select footwear that aligns with your specific needs.

- If your primary focus is maximum support and durability: A steel shank offers the best rigidity for climbing, carrying heavy packs, and working on uneven ground.

- If your primary focus is protection from underfoot punctures: The steel plate provides proven and reliable safeguarding against sharp objects from below.

- If your primary focus is lightweight agility or passing through security: Consider a boot with a composite shank made from nylon or fiberglass to reduce weight and avoid metal detectors.

Ultimately, the steel shank is a feature that transforms a simple boot into a reliable tool for support and protection.

Summary Table:

| Function | Description | Key Benefit |

|---|---|---|

| Structural Support | A rigid plate under the arch that prevents the boot from twisting. | Reduces foot fatigue and provides stability on uneven ground. |

| Puncture Protection | A steel plate in the sole guarding against sharp objects from below. | Essential for safety in hazardous environments like construction sites. |

| Considerations | Compared to lighter composite shanks (nylon, fiberglass). | Steel offers maximum rigidity but is heavier and sets off metal detectors. |

Need Durable, Supportive Footwear for Your Team?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and work footwear, including models with steel shanks for superior support and protection.

We can help you:

- Source reliable footwear that meets rigorous safety and durability standards.

- Develop custom designs tailored to your specific market needs and applications.

- Ensure consistent quality and supply for your business or organization.

Let's discuss your footwear requirements → Contact Our Team Today

Visual Guide

Related Products

- Durable Military Combat Boots with Water Drainage for Wholesale & OEM

- Wholesale Tactical Boots High-Traction & Reflective for Bulk & Brand Orders

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Wholesale Slip-On Safety Boots Manufacturer - Custom Puncture-Proof & Steel Toe

People Also Ask

- What outfits go well with combat lace-up boots? Master the Art of Edgy Style

- What are the primary uses of combat boots? Unmatched Protection for Demanding Environments

- What boot does the Air Force use? Choosing the Right Coyote Brown Boot for Your Role

- Why are slip-resistant military boots important? The Foundation of Soldier Safety and Mission Success

- What is the historical significance of combat boots? From Battlefield Necessity to Cultural Icon