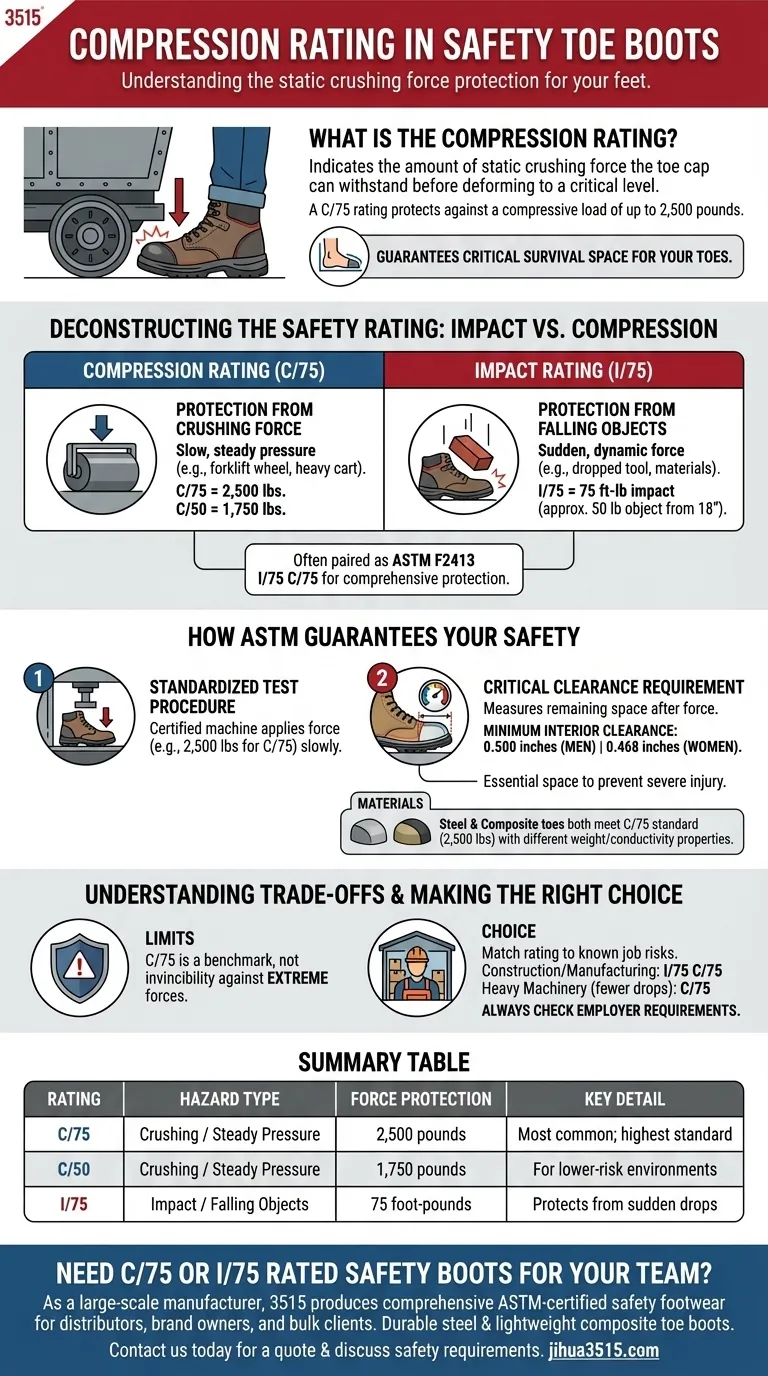

In short, the compression rating on a safety toe boot indicates the amount of static crushing force the toe cap can withstand before it deforms to a critical level. A boot with a C/75 rating, the most common and highest standard, has been tested to protect your toes from a compressive load of up to 2,500 pounds.

The compression rating isn't just about resisting force; it's about a standardized test that guarantees a specific minimum "survival space" for your toes under a heavy, slow-moving load. This makes it a critical measure of protection against crushing injuries.

Deconstructing the Safety Rating: Impact vs. Compression

Workplace safety standards for footwear, such as ASTM F2413, evaluate protection against two distinct types of hazards: compression and impact. Many people use the terms interchangeably, but they represent fundamentally different risks.

The Compression Rating (C/75): Protection from Crushing Force

The compression rating signifies protection against a slow, steady pressure. Think of the wheel of a forklift or a heavy cart slowly rolling onto your foot.

A C/75 rating means the boot has been tested to withstand a force of 2,500 pounds. The less common C/50 rating indicates protection up to 1,750 pounds.

The Impact Rating (I/75): Protection from Falling Objects

The impact rating is about protection from a sudden, dynamic force. This simulates the danger of a heavy tool, a piece of equipment, or a building material being dropped on your foot.

An I/75 rating means the toe cap can protect you from a 75 foot-pound impact. This is equivalent to a 50-pound object being dropped from a height of about 18 inches.

Why Both Ratings Appear Together (e.g., I/75 C/75)

You will almost always see these ratings paired on a boot's label, such as "ASTM F2413 I/75 C/75". This indicates the boot meets the highest standard for both types of hazards.

Workplaces with significant drop hazards often have rolling equipment hazards as well, so comprehensive protection is essential.

How the ASTM Standard Guarantees Your Safety

The numbers on the label are more than just marketing; they represent a specific and rigorous testing protocol designed to ensure a consistent level of safety.

The Standardized Test Procedure

During a compression test, a certified machine applies a steady force to the toe cap of the boot. This force is slowly increased until it reaches the boot's designated rating (e.g., 2,500 lbs for a C/75 rating).

The Critical Clearance Requirement

The test doesn't just measure if the toe cap breaks. The most critical part of the standard is measuring the remaining space, or clearance, inside the toe cap after the full force has been applied.

To pass the C/75 test, the boot must maintain an interior clearance of at least 0.500 inches for men's footwear or 0.468 inches for women's footwear. This is the minimum space deemed necessary to prevent a severe or career-ending injury to the toes.

Materials Used: Steel vs. Composite

Both traditional steel toes and modern composite toes (made from materials like carbon fiber, Kevlar, or plastic) are designed to meet this exact same ASTM performance standard. The material choice affects factors like weight and electrical conductivity, but a C/75 composite toe and a C/75 steel toe both pass the same 2,500-pound compression test.

Understanding the Trade-offs

While essential, it's important to view these ratings with a clear understanding of their purpose and limitations.

The Limits of Protection

A C/75 rating is a benchmark for a specific, tested hazard. It is not a guarantee of invincibility against any and all crushing forces. Extremely heavy machinery or severe accidents can exert forces that exceed the standard's limits.

Misinterpreting the Ratings

A C/50 rating is not "unsafe." It is simply designed for environments with a lower assessed risk of compression hazards. The correct rating is always the one that matches the potential hazards identified in your specific workplace risk assessment. Choosing the highest rating (C/75) is often the safest default if you are unsure.

Making the Right Choice for Your Work

Selecting the correct boot means matching its protective capabilities to the known risks of your job.

- If your primary focus is construction, manufacturing, or warehousing: Look for the I/75 C/75 rating as your baseline, as these environments present frequent risks from both falling objects and heavy rolling equipment.

- If your primary focus is an environment with heavy machinery but fewer drop hazards: The C/75 compression rating remains paramount to protect against crushing incidents from vehicles or equipment.

- If your primary focus is meeting employer requirements: Always check your company's safety policy or ask a supervisor for the specific ASTM standard required for your job site before making a purchase.

Understanding these ratings empowers you to move beyond simple compliance and take active control of your personal safety on the job.

Summary Table:

| Rating | Hazard Type | Force Protection | Key Detail |

|---|---|---|---|

| C/75 | Crushing / Steady Pressure | 2,500 pounds | Most common; highest standard |

| C/50 | Crushing / Steady Pressure | 1,750 pounds | For lower-risk environments |

| I/75 | Impact / Falling Objects | 75 foot-pounds | Protects from sudden drops |

Need C/75 or I/75 rated safety boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of ASTM-certified safety footwear for distributors, brand owners, and bulk clients. We ensure your workers get the highest level of protection with our durable steel toe and lightweight composite toe boots.

Contact us today for a quote and to discuss your specific safety requirements.

Visual Guide

Related Products

- High Performance Fire-Retardant Waterproof Safety Boots

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- How do safety wellington boots differ from standard wellington boots? A Guide to Industrial Footwear Protection

- What are the characteristics of a steel toe? Maximum Impact Protection Explained

- What factors should be considered when choosing between steel and composite toe caps? Ensure Maximum Safety and Comfort

- What are the benefits of steel-toe boots in terms of impact resistance? Get Maximum Protection for Your Workforce

- Why might steel toes be a valuable feature in motorcycle boots? Balancing Protection & Control