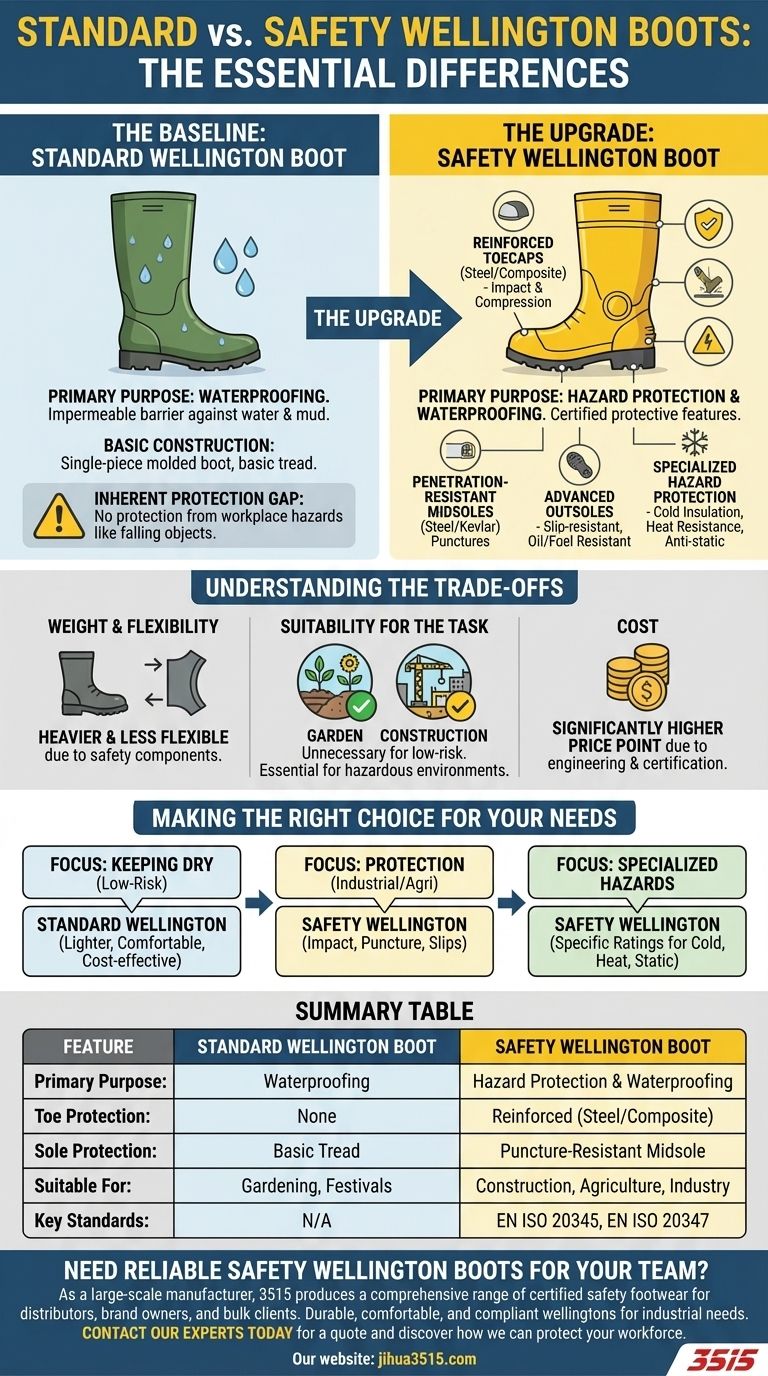

The fundamental difference between safety wellington boots and standard wellingtons is their core purpose. While standard wellingtons are designed solely for waterproofing in wet or muddy conditions, safety wellingtons incorporate specific protective features engineered to shield the wearer from workplace hazards.

The transition from a standard wellington to a safety wellington is a move from passive water protection to active hazard mitigation, equipping the boot with features like reinforced toecaps and penetration-resistant soles required for hazardous environments.

The Baseline: The Standard Wellington Boot

Standard wellingtons, often made of rubber or PVC, serve a single, straightforward function. Their design prioritizes keeping the feet and lower legs dry.

Primary Purpose: Waterproofing

The sole job of a standard wellington is to act as an impermeable barrier against water, mud, and other non-hazardous liquids.

Basic Construction

They are typically a simple, one-piece molded boot reaching just below the knee, with a basic tread for grip in muddy conditions.

The Inherent Protection Gap

Crucially, a standard wellington is not designed to prevent physical injury from workplace accidents like falling objects or sharp debris underfoot.

The Upgrade: Key Features of Safety Wellingtons

Safety wellingtons build upon the waterproof foundation of a standard boot by adding layers of certified protection. These features are what truly distinguish them.

Reinforced Toecaps

This is the most critical feature, providing protection against impact and compression. Toecaps are typically made from steel or lighter composite materials.

Penetration-Resistant Midsoles

A protective plate, often steel or flexible kevlar, is embedded in the sole to prevent sharp objects like nails or glass from piercing through to the foot.

Advanced Outsoles

The outsoles on safety wellingtons are engineered for performance. They often feature enhanced slip-resistance and are made from compounds that resist degradation from oil and fuel.

Specialized Hazard Protection

Modern safety wellingtons can be tailored to specific industrial risks. This includes features like cold insulation for low-temperature work, heat resistance for high-temperature environments, and anti-static properties to prevent electrostatic discharge.

Understanding the Trade-offs

Choosing a safety wellington involves acknowledging a few key differences in wearability and cost that stem directly from their protective features.

Weight and Flexibility

The addition of steel toecaps, midsoles, and thicker soles makes safety wellingtons noticeably heavier and less flexible than their standard counterparts.

Cost

The engineering, specialized materials, and safety certifications required for these boots result in a significantly higher price point.

Suitability for the Task

For low-risk activities like gardening or casual walks, the added weight and rigidity of a safety wellington can be uncomfortable and unnecessary. The right tool is always determined by the task.

Making the Right Choice for Your Needs

Selecting the correct boot depends entirely on a clear assessment of your environment and potential risks.

- If your primary focus is keeping dry in low-risk environments: A standard wellington is the lighter, more comfortable, and cost-effective choice.

- If your primary focus is protection in industrial or agricultural settings: A safety wellington is essential to protect against impact, punctures, and slips.

- If your primary focus is dealing with specialized hazards: You must select a safety wellington with the specific ratings for cold, heat, or static electricity that your job requires.

Ultimately, understanding the distinction empowers you to choose the precise level of protection your environment demands.

Summary Table:

| Feature | Standard Wellington Boot | Safety Wellington Boot |

|---|---|---|

| Primary Purpose | Waterproofing | Hazard Protection & Waterproofing |

| Toe Protection | None | Reinforced (Steel/Composite) |

| Sole Protection | Basic Tread | Puncture-Resistant Midsole |

| Suitable For | Gardening, Festivals | Construction, Agriculture, Industry |

| Key Standards | N/A | EN ISO 20345, EN ISO 20347 |

Need reliable safety wellington boots for your team?

As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. We offer durable, comfortable, and fully compliant safety wellingtons tailored to your specific industrial needs.

Contact our experts today for a quote and discover how we can protect your workforce.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- High Performance Fire-Retardant Waterproof Safety Boots

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

People Also Ask

- How were Wellington boots used in World War II? Essential Gear for Wet Battlefields

- What are the steps for cleaning Wellington boots? A Simple Guide to Preserve Your Boots for Years

- How do waterproof materials contribute to the functionality of Wellington boots? Unlock the Secrets of Staying Dry

- What are the benefits of ankle wellies for women? Style, Comfort & Everyday Convenience

- What features make mid-calf Wellington boots ideal for everyday wear? Discover the Perfect Balance of Protection & Comfort

- Which industries use PVC boots? Essential Footwear for Wet & Chemical Work

- Who developed Wellington boots and what was their original purpose? From Military Necessity to Modern Icon

- How are gumboots packaged and distributed? Ensure Product Integrity from Factory to Customer