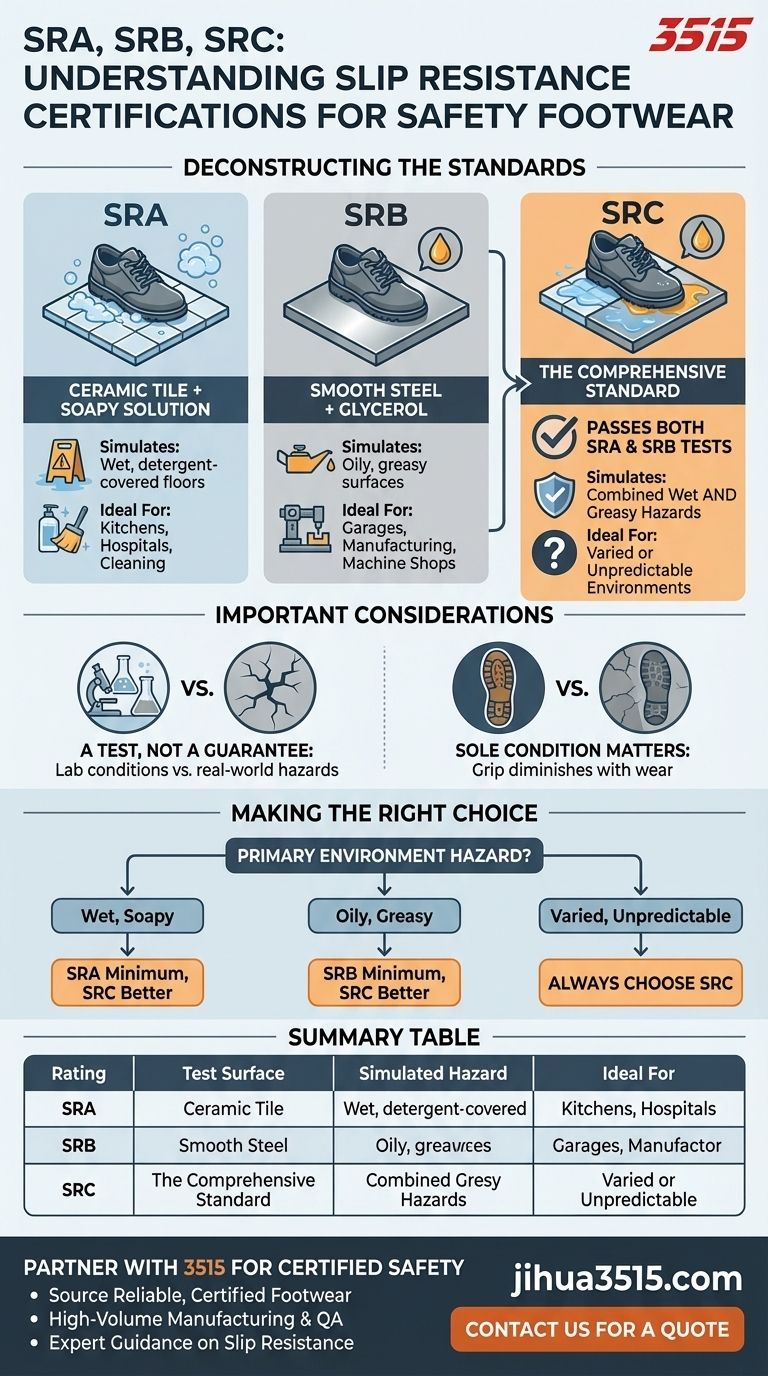

To understand slip resistance certifications, you must look at the specific surfaces and contaminants they are tested against. SRA certification indicates a shoe has passed a slip resistance test on a ceramic tile floor wetted with a dilute soap solution. SRB means it has passed a test on a smooth steel floor with glycerol. Footwear marked with SRC has passed both the SRA and SRB tests.

The core takeaway is that slip resistance ratings are not equal. SRC represents the most comprehensive and highest standard of slip resistance, as it certifies performance on both common wet and greasy surfaces, while SRA and SRB are specific to one type of hazard.

Deconstructing the Slip Resistance Ratings

Each rating corresponds to a highly specific, standardized laboratory test designed to simulate common workplace slip hazards. Understanding the test environment is key to choosing the right footwear.

The SRA Standard: Wet Ceramic Surfaces

The SRA test is performed on a ceramic tile surface wetted with sodium lauryl sulphate (NaLS), which is essentially a soapy water solution.

This test simulates conditions frequently found in environments like commercial kitchens, food processing plants, hospitals, and cleaning industries, where water and detergents are common on tiled floors.

The SRB Standard: Oily Steel Surfaces

The SRB test uses a smooth steel surface coated with glycerol. Glycerol is used to simulate oils, greases, and lubricants.

This test is designed to replicate hazards in industrial settings such as automotive garages, machine shops, and manufacturing facilities where contact with oily substances on smooth floors is a daily risk.

The SRC Standard: The Comprehensive Certification

A shoe is not tested for SRC. Instead, this rating is awarded only when a piece of footwear has successfully passed both the SRA and the SRB tests.

Therefore, SRC provides the highest level of assurance. It tells you the footwear's sole offers proven slip resistance on both the most common wet and greasy surfaces, making it suitable for a wider range of environments.

Understanding the Trade-offs and Limitations

While these certifications are a critical safety benchmark, it's important to understand what they do and do not guarantee. They provide a reliable baseline for performance under controlled conditions.

A Test, Not a Guarantee

These are laboratory tests on pristine, specific surfaces. Real-world floors can have different textures, unevenness, and a mix of contaminants not covered by the tests. The rating is a powerful indicator, but not an absolute promise against all slips.

The Critical Role of Sole Condition

The slip resistance rating applies to the footwear when it is new. As the sole tread wears down, its ability to grip and channel away liquids diminishes significantly.

An SRC-rated boot with a worn, smooth sole will not provide the certified level of protection. Regular inspection of your footwear is a crucial part of maintaining safety.

Making the Right Choice for Your Environment

Selecting the appropriate slip resistance rating is a critical decision for workplace safety. Use the specific hazards of your environment as your guide.

- If your primary focus is wet, soapy floors (e.g., kitchens, food service): SRA is the minimum standard, but SRC offers more versatile protection should other hazards be present.

- If your primary focus is oily or greasy steel surfaces (e.g., garages, manufacturing): SRB is the essential minimum requirement, though SRC is the more robust choice.

- If your primary focus is safety in varied or unpredictable environments: Always choose SRC-rated footwear for the highest and most comprehensive level of slip protection.

Ultimately, matching your footwear's certified capabilities to your workplace risks is the most effective way to prevent slips and falls.

Summary Table:

| Rating | Test Surface | Simulated Hazard | Ideal For |

|---|---|---|---|

| SRA | Ceramic tile with soapy water | Wet, detergent-covered floors | Kitchens, hospitals, cleaning |

| SRB | Smooth steel with glycerol | Oily, greasy surfaces | Garages, machine shops, manufacturing |

| SRC | Passes both SRA and SRB tests | Combined wet AND greasy hazards | Varied or unpredictable environments |

Ensure Your Team Has the Right Slip Protection

As a large-scale manufacturer, 3515 produces a comprehensive range of SRA, SRB, and SRC-certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, designed to meet the specific hazards of your industry.

Partner with us to:

- Source reliable, certified safety footwear that reduces workplace accidents.

- Benefit from high-volume manufacturing and consistent quality control.

- Get expert guidance on selecting the right slip resistance rating for your needs.

Protect your workforce with the right gear. Contact our team today for a quote and more information.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

People Also Ask

- What materials are used to make safety toes? Choose the Right Protection for Your Job

- Why wear protective masks, gloves, and safety shoes in 5S Shine? Elevate Safety and Discipline

- Why is toe room important in work shoes? Ensure All-Day Comfort and Prevent Injury

- What factors should be considered when choosing between steel-toe and soft-toe boots? Ensure Safety and Comfort

- What are the signs that safety toe boots are worn out and need replacement? Ensure Your Workplace Safety

- How do safety shoes protect against electrical hazards? Essential Features for Workplace Safety

- What are the pros and cons of composite safety toes? Weighing Weight vs. Ultimate Protection

- What are the technical and construction advantages of professional-grade Safety Shoes? Enhance Stability and Grip