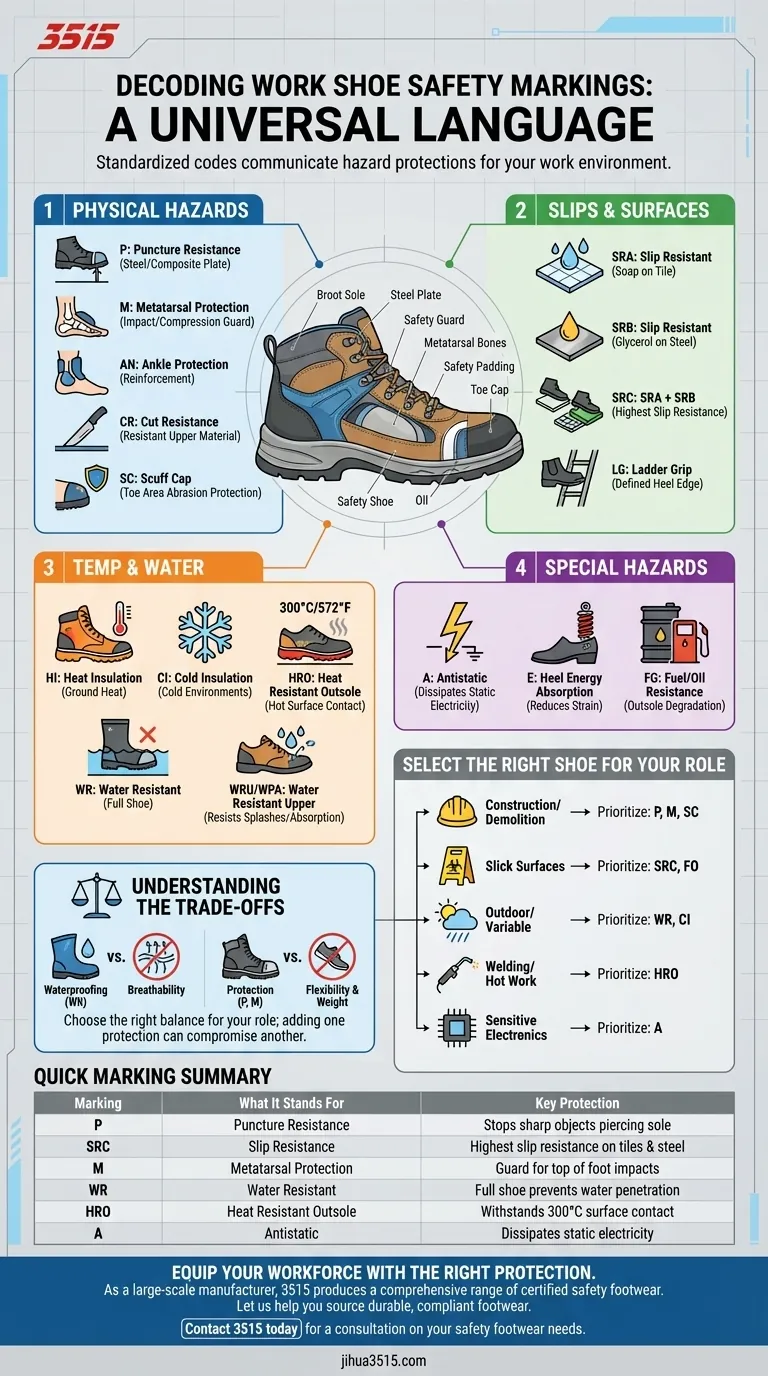

At their core, markings on work shoes are a universal safety language. These standardized codes, such as 'P' for puncture resistance or 'SRC' for slip resistance, communicate the specific hazards a shoe is certified to protect you from. Understanding them is the first step in ensuring you have the right protection for your work environment.

The collection of letter codes on your safety footwear isn't arbitrary. It's a precise specification sheet that details the shoe's protective capabilities, allowing you to match your gear directly to the risks you face on the job.

Decoding the Core Safety Features

To select the right footwear, you must first be able to translate its markings. These codes are typically found on the tongue or inner lining of the shoe and cover a wide range of protections, from physical impacts to environmental hazards.

Protection from Physical Hazards

These markings indicate resistance to direct physical threats like punctures, impacts, or cuts.

- P (Puncture Resistance): The sole has a built-in plate (steel or composite) to protect against nails or other sharp objects from piercing through from below.

- M (Metatarsal Protection): A guard is integrated over the top of the foot to protect the delicate metatarsal bones from impact or compression.

- AN (Ankle Protection): The shoe includes additional reinforcement or padding to protect the ankle area from impacts.

- CR (Cut Resistance): The shoe's upper material is designed to resist cuts from sharp objects, a crucial feature for those working with blades or sheet metal.

- SC (Scuff Cap): A reinforced cap, often made of durable rubber or composite, is added to the toe area to protect against abrasion and extend the shoe's life.

Resistance to Slips and Surfaces

This is one of the most critical safety categories, as slips, trips, and falls are a leading cause of workplace injuries.

- SRA: Tested and certified for slip resistance on a ceramic tile surface wetted with a soap solution.

- SRB: Tested and certified for slip resistance on a steel surface with glycerol.

- SRC: The highest level of slip resistance, indicating the shoe has passed both SRA and SRB tests.

- LG (Ladder Grip): The heel of the sole is designed with a defined edge to provide better grip and stability when climbing ladders.

Resistance to Temperature and Water

These codes certify the shoe's performance in extreme temperatures or wet conditions.

- HI (Heat Insulation): The sole provides insulation against high temperatures from the ground up.

- CI (Cold Insulation): The shoe's materials provide insulation against cold, keeping your feet warm in low-temperature environments.

- HRO (Heat Resistant Outsole): The outsole can withstand contact with a hot surface at 300°C (572°F) for one minute without melting or cracking.

- WR (Water Resistant): The entire shoe is constructed to prevent water from penetrating, making it suitable for consistently wet environments.

- WRU / WPA (Water Resistant Upper / Water Penetration & Absorption): Only the upper material of the shoe is treated to resist water. This offers protection from splashes but is not fully waterproof.

Protection Against Special Hazards

This category covers risks related to chemicals, electricity, or high-impact energy.

- A (Antistatic): The footwear is designed to dissipate static electricity, reducing the risk of spark ignition of flammable substances or damage to sensitive electronic components.

- E (Heel Energy Absorption): The heel region is designed to absorb impact energy, reducing strain on the wearer's feet and legs.

- FO (Fuel/Oil Resistance): The outsole is made from a compound that resists damage and degradation from contact with hydrocarbons like fuel and oil.

Understanding the Trade-offs

Selecting safety footwear is rarely about finding a single shoe with every feature. More often, it's about choosing the right balance of features for your specific role, as adding one protection can sometimes compromise another.

Waterproofing vs. Breathability

A fully WR-rated boot is excellent for keeping water out, but its construction can limit air circulation. In hot environments, this can lead to excessive sweating and discomfort. A WRU shoe offers a compromise, providing some water resistance while often allowing for better breathability.

Protection vs. Flexibility and Weight

Features like a steel puncture-resistant plate (P) or a metatarsal guard (M) add critical protection but also increase the shoe's weight and rigidity. This can lead to fatigue over a long workday. Modern composite materials can reduce this trade-off but are often found at a higher price point.

Specialization vs. General Use

A shoe with a highly specialized sole, such as one rated HRO for heat resistance, may not have the same slip-resistance profile or flexibility as a standard SRC-rated sole. Always prioritize the marking that protects you from the most significant and frequent hazard in your workplace.

How to Select the Right Shoe for Your Role

Your job-site risk assessment should be the ultimate guide for your footwear choice. By matching the known hazards to the shoe's markings, you can make an informed and safe decision.

- If your primary focus is construction or demolition: Prioritize P (puncture), M (metatarsal), and SC (scuff cap) to protect against falling objects and sharp debris.

- If your primary focus is working on slick surfaces like kitchens or automotive shops: An SRC (slip resistance) and FO (oil resistance) rating is non-negotiable.

- If your primary focus is outdoor work in variable weather: Look for WR (water-resistant) for wet conditions and CI (cold insulation) for winter months.

- If your primary focus is welding or working around hot materials: HRO (heat-resistant outsole) is a critical feature to prevent sole damage and protect your feet.

- If your primary focus is working with sensitive electronics: You must have A (antistatic) footwear to prevent static discharge from damaging components.

By learning to read these codes, you are taking direct control over your personal safety on the job.

Summary Table:

| Marking | What It Stands For | Key Protection Provided |

|---|---|---|

| P | Puncture Resistance | Steel/composite plate stops sharp objects piercing the sole |

| SRC | Slip Resistance | Highest rating for slip resistance on wet tiles and steel |

| M | Metatarsal Protection | Guard protects the top of the foot from impacts |

| WR | Water Resistant | Full shoe construction prevents water penetration |

| HRO | Heat Resistant Outsole | Withstands contact with surfaces up to 300°C |

| A | Antistatic | Dissipates static electricity to prevent sparks |

Ensure your workforce is equipped with the right protection. As a large-scale manufacturer, 3515 produces a comprehensive range of certified safety footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety shoes and boots, designed to meet the specific hazard markings your industry requires. Let us help you source durable, compliant footwear that keeps your team safe and productive.

Contact 3515 today for a consultation on your safety footwear needs.

Visual Guide

Related Products

- Premium Suede Sport Safety Shoes for Wholesale & Bulk Orders

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

People Also Ask

- What types of hazards does protective footwear guard against? Ensure Workplace Foot Safety

- What are the functions of the lining material in safety footwear? Unlock All-Day Comfort & Performance

- Why is a specific neutralizing buffer required for safety shoe disinfection? Ensure Data Accuracy with Dey-Engley Broth

- What core functions do professional safety shoes serve? Enhance Construction & Industrial Safety Standards

- How do soft-toe and composite-toe boots compare in terms of performance? Choose the Right Boot for Your Job

- What role do industrial safety shoes play in OHS management? Enhancing Workforce Protection and Safety Culture

- What makes S3 safety shoes suitable for high-risk work environments? A Guide to Multi-Hazard Protection

- What are the main protection classes for safety shoes? A Guide to S1, S3, S5 & More