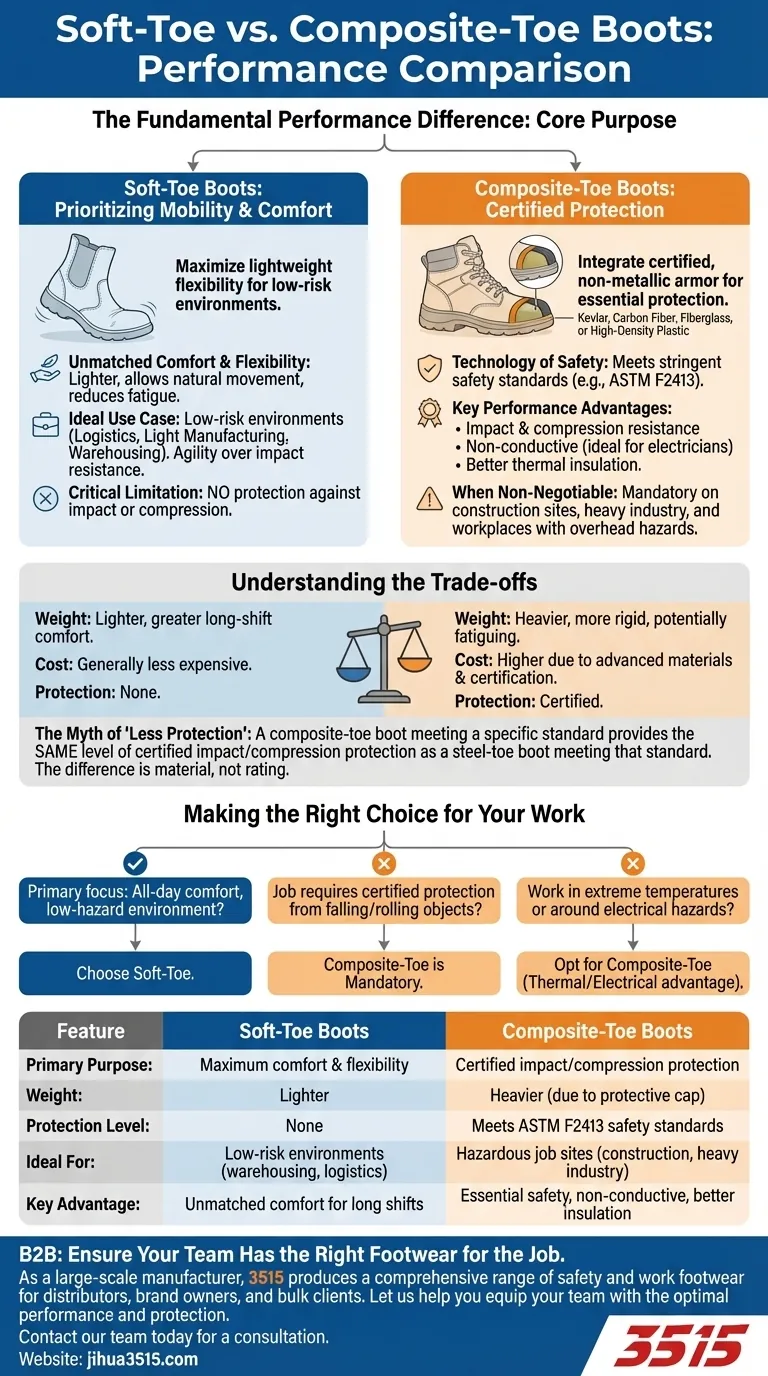

The fundamental performance difference between soft-toe and composite-toe boots lies in their core purpose. Soft-toe boots are engineered to maximize lightweight flexibility and comfort for low-risk environments, while composite-toe boots integrate certified, non-metallic armor to provide essential impact protection for hazardous job sites.

Choosing between soft-toe and composite-toe is not a matter of preference but a function of risk assessment. The correct choice hinges entirely on whether your work environment mandates certified protection against impact and compression hazards.

The Case for Soft-Toe Boots: Prioritizing Mobility

A soft-toe boot is defined by what it lacks: a reinforced, protective toe cap. This design choice is intentional and centers on performance for specific environments.

Unmatched Comfort and Flexibility

Without a rigid cap, the boot is lighter and allows for more natural foot movement. This significantly reduces fatigue over long shifts that involve extensive walking, standing, or climbing.

The Ideal Use Case

Soft-toe boots are the superior choice for professions where the risk of heavy falling or rolling objects is negligible. This includes roles in logistics, light manufacturing, warehousing, and certain trades where agility is more critical than impact resistance.

The Critical Limitation

It is essential to understand that soft-toe boots offer no protection against impact or compression. They are simply standard footwear in a boot form factor and should never be used where safety regulations mandate a protective toe.

The Role of Composite-Toe Boots: Certified Protection

Composite-toe boots represent a modern approach to worksite safety, using advanced materials to shield the wearer from serious injury.

The Technology of Safety

The "composite" name refers to non-metallic materials like Kevlar, carbon fiber, fiberglass, or high-density plastic. These materials are engineered into a protective cap that meets the same stringent safety standards (e.g., ASTM F2413 in the United States) as traditional steel-toe boots.

Key Performance Advantages

The primary function of a composite toe is impact and compression resistance, protecting your feet from falling tools or rolling equipment. Because they are non-metallic, they do not conduct electricity, making them ideal for electricians. They also don't transfer cold or heat as readily as steel, offering better insulation in extreme temperatures.

When They Are Non-Negotiable

A certified safety-toe boot is mandatory on most construction sites, in heavy industrial settings, and any workplace with active machinery or overhead hazards. For these jobs, a composite-toe is not an upgrade; it's a requirement.

Understanding the Trade-offs

Neither boot is universally "better." The optimal choice depends entirely on balancing the performance characteristics against the demands of your job.

Weight vs. Protection

The most significant trade-off is weight. While composite toes are lighter than steel, they are noticeably heavier and more rigid than soft toes. This added weight is the price of protection and can lead to greater fatigue if you don't actually need the safety feature.

Cost and Durability

The advanced materials and certification process make composite-toe boots more expensive than their soft-toe counterparts. The rigid cap also creates a distinct flex point on the boot, which can sometimes be a point of wear over time.

The Myth of "Less Protection"

A common misconception is that composite toes are less protective than steel toes. This is incorrect. A composite-toe boot that meets a specific safety standard provides the exact same level of certified impact and compression protection as a steel-toe boot meeting that same standard. The difference lies in material properties, not safety rating.

Making the Right Choice for Your Work

Evaluate your daily tasks and environment to determine the correct level of performance and protection you require.

- If your primary focus is all-day comfort in a low-hazard environment: Choose a soft-toe boot for maximum flexibility and reduced weight.

- If your job requires certified protection from falling or rolling objects: A composite-toe boot is the mandatory and correct choice for your safety.

- If you work in extreme temperatures or around electrical hazards: Opt for a composite-toe, as its non-metallic properties offer a significant thermal and electrical advantage.

Ultimately, the best boot is the one that correctly matches its protective capabilities to the real-world risks of your workday.

Summary Table:

| Feature | Soft-Toe Boots | Composite-Toe Boots |

|---|---|---|

| Primary Purpose | Maximum comfort & flexibility | Certified impact/compression protection |

| Weight | Lighter | Heavier (due to protective cap) |

| Protection Level | None | Meets ASTM F2413 safety standards |

| Ideal For | Low-risk environments (warehousing, logistics) | Hazardous job sites (construction, heavy industry) |

| Key Advantage | Unmatched comfort for long shifts | Essential safety, non-conductive, better insulation |

Ensure Your Team Has the Right Footwear for the Job

As a large-scale manufacturer, 3515 produces a comprehensive range of safety and work footwear for distributors, brand owners, and bulk clients. Whether your workforce requires the lightweight comfort of soft-toe boots or the certified protection of composite-toe boots, we have the production capabilities and expertise to meet your needs.

Let us help you equip your team with the optimal performance and protection.

Contact our team today for a consultation to discuss your specific requirements and volume orders.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- Why are safety shoes mandatory for historical stone cleaning? Essential Gear for Restoration Projects

- How do safety shoes protect workers in precast concrete production? Essential Steel Toe and Midsole Protection Guide

- What are the requirements for a protective toe cap? Meet ASTM F2413 Standards for Maximum Safety

- What is a safety-toe in a boot? Your Guide to Choosing the Right Protection

- What protective functions do safety shoes provide in construction safety? Maximize Site Safety and Reduce Downtime