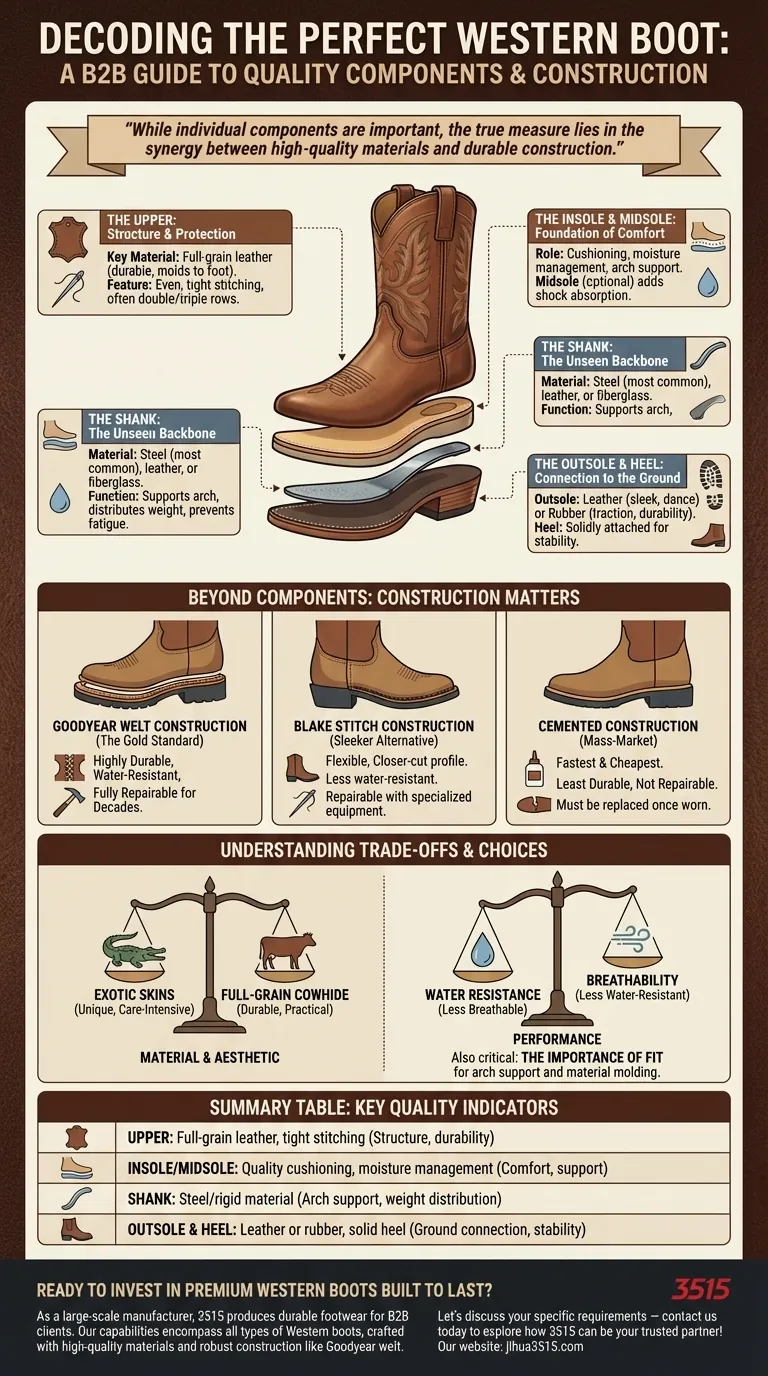

At its core, a high-quality Western boot is defined by four critical components. These are the upper, which provides structure and protection; the insole, which delivers comfort and support; the outsole and heel, which create the connection to the ground; and the internal shank, the boot’s unseen backbone. The quality of these parts and how they are assembled determines the boot's overall performance and longevity.

While individual components are important, the true measure of a superior Western boot lies in the synergy between high-quality materials and durable construction methods. Understanding this relationship is the key to identifying a boot that will last a lifetime.

The Anatomy of a Superior Boot

A well-made boot is an integrated system where each part plays a specific role. Examining these components individually reveals the hallmarks of quality craftsmanship.

The Upper: The Boot's First Line of Defense

The upper is the entire part of the boot that covers your foot and ankle. Its primary job is to provide structure, durability, and protection.

The best boots almost always use full-grain leather. This is the highest quality grade, using the strongest part of the hide, which is durable, breathable, and molds to your foot over time. Other options include top-grain leather, exotic skins like alligator or snake, and modern synthetic materials.

Pay close attention to the stitching. High-quality boots feature even, tight stitching, often with double or triple rows in high-stress areas to ensure the upper won't separate.

The Insole & Midsole: The Foundation of Comfort

The insole is the layer your foot rests on directly. A quality insole provides essential cushioning, moisture management, and initial arch support.

Some modern boots also include a midsole, a layer between the insole and outsole that offers additional shock absorption, making the boot more comfortable for walking on hard surfaces.

The Shank: The Unseen Backbone

The shank is perhaps the most critical component for long-term support. It is a stiff, narrow strip of material (typically steel, but sometimes leather or fiberglass) placed between the insole and outsole.

Its function is to support the arch of your foot and distribute your weight evenly. Without a quality shank, a boot will feel flimsy and can cause significant foot fatigue.

The Outsole & Heel: Your Connection to the Ground

The outsole is the part that makes contact with the ground. Traditional boots use a leather outsole, which is sleek and ideal for the stirrup or the dance floor.

Modern boots often feature rubber outsoles for superior traction, slip resistance, and durability, making them better suited for walking or working. The heel must be solidly attached and made of a durable material to provide stability.

Beyond the Parts: How a Boot Is Built Matters Most

Two boots can be made of the same materials, but the construction method used to join the upper to the sole will dictate their durability, water resistance, and repairability.

The Gold Standard: Goodyear Welt Construction

A Goodyear welt is a method where a strip of leather (the "welt") is stitched to the upper and the insole. The outsole is then stitched directly to this welt.

This creates a highly durable, water-resistant seam. Most importantly, it allows a cobbler to easily remove the old outsole and stitch on a new one, making the boot fully repairable for decades of use.

The Sleeker Alternative: Blake Stitch Construction

In a Blake stitch, the upper is stitched directly to the outsole from the inside. This results in a more flexible boot with a closer-cut, less chunky profile.

While still a quality construction method, it is less water-resistant than a Goodyear welt. Resoling is possible but requires specialized machinery and expertise.

The Mass-Market Method: Cemented Construction

This involves simply gluing the sole directly to the upper. It is the fastest and cheapest method of construction.

The trade-off is significant: cemented boots are the least durable and are almost never repairable. Once the sole separates or wears out, the boot must be replaced.

Understanding the Trade-offs

Choosing the right boot involves balancing features with intended use. There is no single "best" boot, only the best boot for your specific needs.

Exotic Skins vs. Cowhide

Exotic skins offer a unique aesthetic but often require more specialized care. For pure, rugged, daily wear, a high-quality full-grain cowhide is typically the most durable and practical choice.

Water Resistance vs. Breathability

True "waterproof" boots often rely on a synthetic membrane inside the leather. This can be effective at keeping water out, but it will always reduce the natural breathability of the leather, which can lead to sweaty, uncomfortable feet.

The Importance of Fit

The highest quality materials and construction mean nothing if the boot does not fit correctly. A proper fit ensures the shank is supporting your arch properly and allows the leather upper to mold perfectly to the unique shape of your foot.

Making the Right Choice for Your Goal

Select your boot based on a clear understanding of its components and your primary intended use.

- If your primary focus is longevity and rugged use: Prioritize a full-grain leather upper with a Goodyear welt construction and a durable rubber outsole.

- If your primary focus is dress wear or a sleeker profile: A Blake-stitched boot made from high-quality leather or an exotic skin is an excellent choice.

- If your primary focus is all-day comfort for walking: Look for a boot with a quality cushioned insole, a supportive steel shank, and a flexible outsole.

Ultimately, a great Western boot is an investment in craftsmanship that pays dividends in comfort and durability for years to come.

Summary Table:

| Component | Key Quality Indicator | Role & Benefit |

|---|---|---|

| Upper | Full-grain leather, tight stitching | Provides structure, durability, and molds to your foot |

| Insole/Midsole | Quality cushioning, moisture management | Delivers comfort, arch support, and shock absorption |

| Shank | Steel or rigid material | Supports the arch, distributes weight, prevents fatigue |

| Outsole & Heel | Leather for style, rubber for traction | Creates ground connection, ensures stability and durability |

Ready to invest in premium Western boots built to last?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of Western boots, crafted with high-quality materials like full-grain leather and robust construction methods such as Goodyear welt for superior longevity.

We ensure every boot delivers exceptional comfort, support, and durability tailored to your needs—whether for rugged use, dress wear, or all-day walking.

Let's discuss your specific requirements — contact us today to explore how 3515 can be your trusted partner for high-performance Western boots!

Visual Guide

Related Products

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- High Performance Fire-Retardant Waterproof Safety Boots

People Also Ask

- What physical protections are provided by the S1 standard and integrated steel toecaps in industrial safety boots? Ensure Ultimate Foot Safety & Hazard Protection

- What are the primary safety functions of safety boots with steel-toe designs? Essential Protection for Industry

- What specific mechanical protections do industrial safety shoes provide in cable factories? Expert Guide for Max Safety

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- Why is the last important in work boot design? It's the Anatomical Blueprint for Comfort & Safety