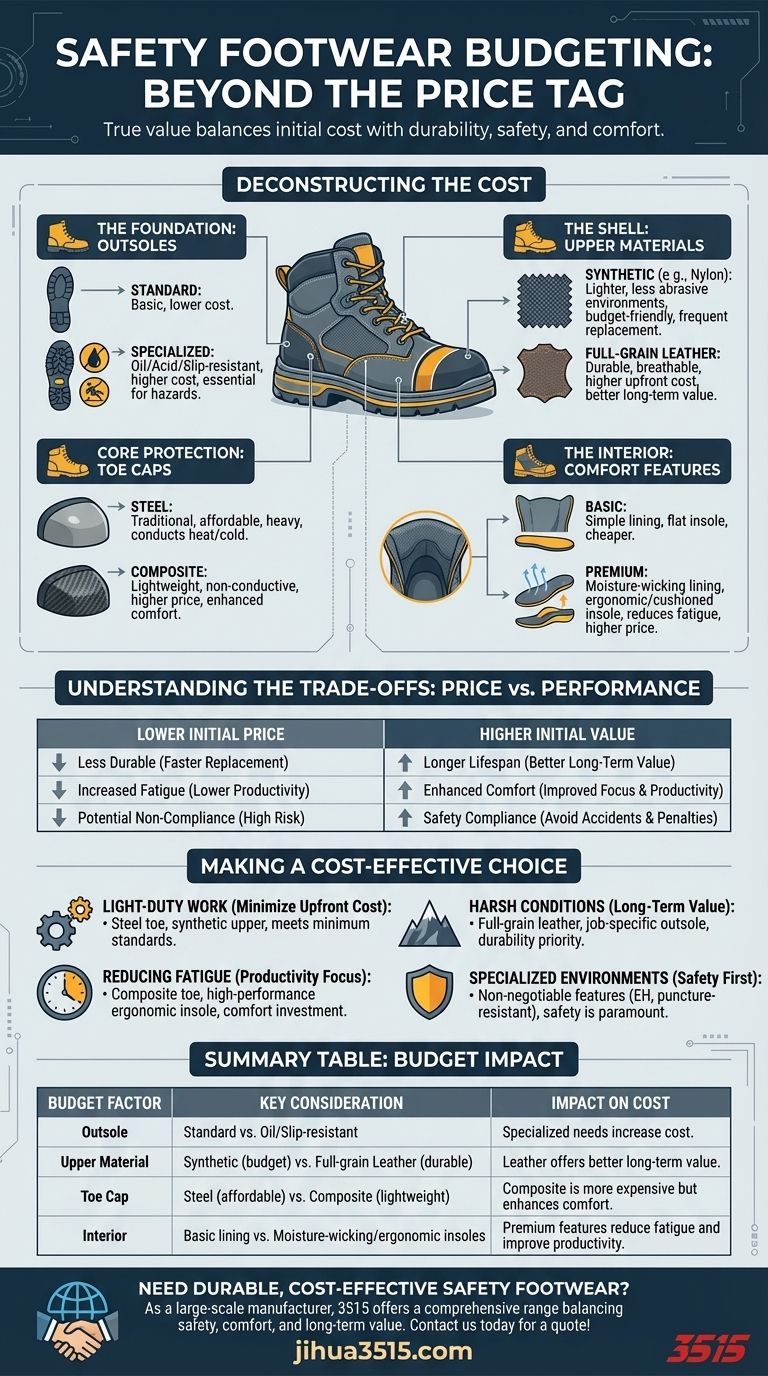

When budgeting for safety footwear, the key is to look beyond the initial price tag. The cost of a work boot is determined by a combination of its core components, including the outsole material, the upper material (like leather or nylon), the type of protective toe cap (steel vs. composite), and internal comfort features such as the lining and insole. Each choice represents a trade-off between price, durability, comfort, and specialized protection.

The most cost-effective safety footwear isn't necessarily the cheapest option. True value comes from balancing the initial purchase price with long-term durability, the specific safety requirements of your job, and the impact of comfort on daily productivity.

Deconstructing the Cost: Key Components and Their Budget Impact

To make an informed budget decision, you must understand what you are paying for. Each part of the boot serves a purpose, and its material and construction directly influence the final cost.

The Foundation: Outsole Materials and Design

The outsole is your connection to the ground. A basic, general-purpose sole is standard, but specialized needs increase the cost.

Outsoles designed to be oil- and acid-resistant or provide enhanced slip resistance use more advanced rubber or polyurethane compounds, which adds to the price. These are non-negotiable in environments where such hazards are present.

The Shell: Upper Materials (Leather vs. Synthetics)

The material of the boot's upper dictates its durability, breathability, and cost.

Full-grain leather is a premium material, offering maximum durability and breathability. It has a higher upfront cost but often results in a longer-lasting boot, providing better long-term value.

Synthetic materials, like nylon mesh, are lighter and typically less expensive. They are a good budget option for less abrasive environments but may need to be replaced more frequently.

The Core Protection: Toe Caps and Midsoles

The protective elements are critical for safety and are a major factor in the boot's price and feel.

Steel toe caps are the traditional, more affordable option. They offer excellent protection but are heavier and conduct heat and cold, which can be a drawback in extreme temperatures.

Composite toe caps, made from materials like carbon fiber or plastic, are significantly lighter and do not conduct electricity or temperature. This enhanced comfort and functionality comes at a higher price point.

The Interior: Linings and Insoles

Comfort is not a luxury; it's a feature that impacts safety and productivity.

Basic footwear may have a simple lining. Premium boots often include breathable, moisture-wicking, and antibacterial linings to manage sweat and odor, adding to the cost but dramatically improving all-day comfort.

Similarly, a basic flat insole is cheap, while an ergonomic or cushioned insole designed for shock absorption and arch support will increase the price. This investment can significantly reduce foot fatigue.

Understanding the Trade-offs: Price vs. Performance

A low price tag can be tempting, but it often comes with hidden costs. Evaluating these trade-offs is essential for making a smart investment.

Durability and Replacement Costs

A cheaper boot made with lower-quality materials may wear out in six months. A more expensive, durable boot might last for two years under the same conditions. In this scenario, the "expensive" boot is actually the more budget-friendly choice over time.

Comfort and Worker Productivity

Uncomfortable footwear is a constant distraction that leads to fatigue. Investing in lighter composite toes or better insoles can improve focus and reduce end-of-day exhaustion, directly contributing to better work performance.

Compliance and Safety Risks

This is the most critical trade-off. Saving money by forgoing a feature required by your worksite (like electrical hazard protection or a puncture-resistant sole) is a false economy. The cost of a single workplace accident far exceeds the savings on footwear. Always ensure your choice meets or exceeds your required safety standards.

Making a Cost-Effective Choice for Your Work

Align your budget with the specific demands of your job to find the best value.

- If your primary focus is minimizing upfront cost for light-duty work: Look for boots with steel toes and durable synthetic uppers, ensuring they still meet all minimum safety standards for your role.

- If your primary focus is long-term value in harsh conditions: Invest in footwear with full-grain leather uppers and high-quality, job-specific outsoles.

- If your primary focus is reducing fatigue from long hours on your feet: Prioritize lightweight composite toes and high-performance ergonomic insoles, even if the initial cost is higher.

- If your primary focus is safety in specialized environments: Your budget must first accommodate non-negotiable features like electrical hazard (EH) ratings or puncture-resistant soles before considering other comfort or material choices.

A well-informed budget decision protects both your feet and your bottom line.

Summary Table:

| Budget Factor | Key Consideration | Impact on Cost |

|---|---|---|

| Outsole | Standard vs. oil/slip-resistant | Specialized needs increase cost |

| Upper Material | Synthetic (budget) vs. Full-grain Leather (durable) | Leather offers better long-term value |

| Toe Cap | Steel (affordable) vs. Composite (lightweight) | Composite is more expensive but enhances comfort |

| Interior | Basic lining vs. Moisture-wicking/ergonomic insoles | Premium features reduce fatigue and improve productivity |

Need durable, cost-effective safety footwear for your team? As a large-scale manufacturer, 3515 produces a comprehensive range of safety boots and shoes for distributors, brand owners, and bulk clients. We offer the perfect balance of safety, comfort, and long-term value to protect your workers and your budget. Contact us today for a quote and find the ideal solution for your needs!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Advanced KPU Athletic Safety Shoe with Steel Toe Cap Anti-Slip Rotary Lacing System

- Wholesale Premium Waterproof Nubuck Safety Shoes Boots

- Premium Suede Metatarsal Guard Safety Boots Work Shoes

People Also Ask

- How does the hand lay-up method contribute to the fabrication of composite toe caps? Master Precision Engineering

- Why is it necessary to balance safety shoe protection with flexibility? Optimize Worker Comfort and Agility

- Why is the implementation of process management essential for safety shoes? Boost Efficiency & TQM Standards

- How does puncture-resistant footwear work? Your Ultimate Guide to Foot Safety

- What is the design purpose of specialized electrodes in EVA safety shoe testing? Ensure Real-World Insulation Safety

- What are the common types of safety boots and their primary uses? A Guide to Industrial Footwear

- What role do professional safety shoes play in addressing balance and gait issues? Enhance Workplace Stability and Confidence

- Why is slip resistance important in safety footwear? Prevent Costly Workplace Slips and Falls