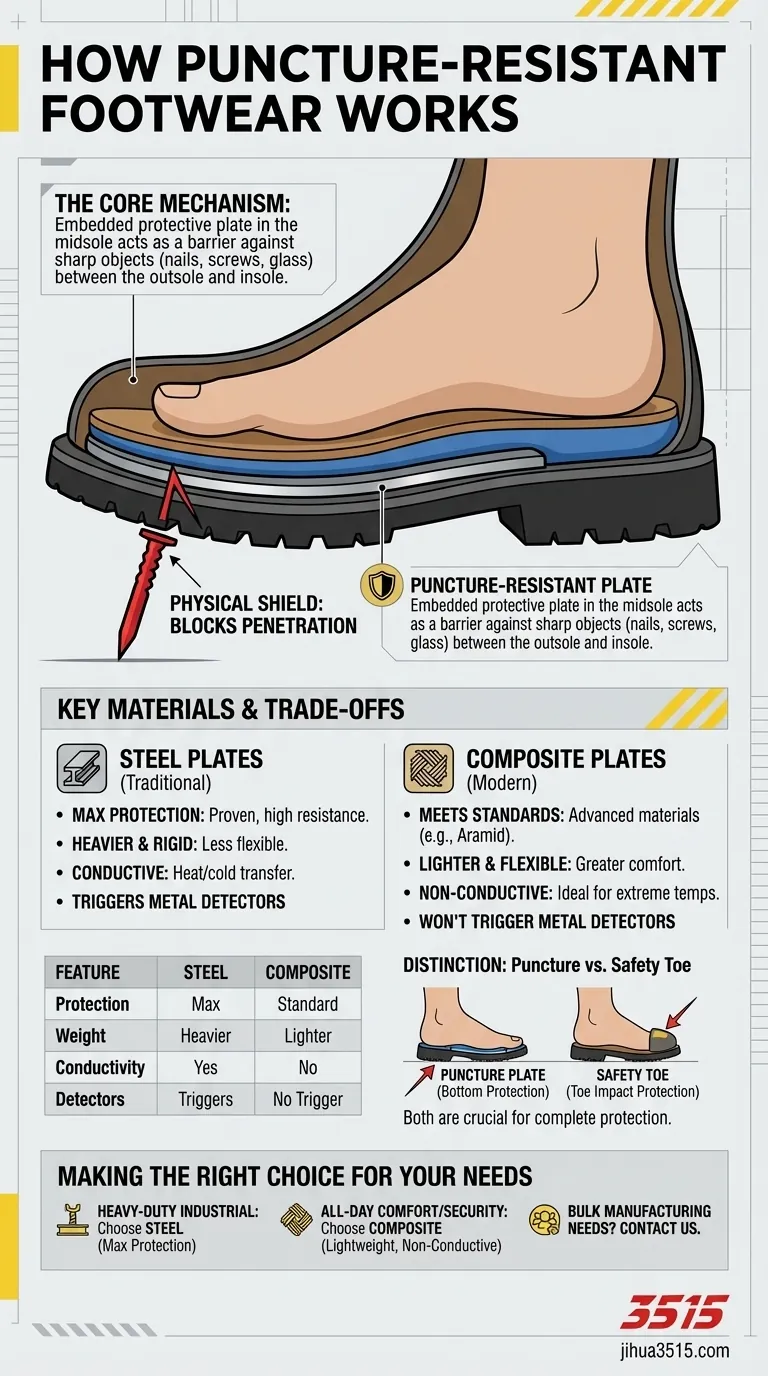

At its core, puncture-resistant footwear works by embedding a protective plate into the midsole of the boot or shoe. This plate acts as a physical shield, positioned directly between the outsole that contacts the ground and the insole that supports your foot, preventing sharp objects like nails, screws, or glass from penetrating through to injure you.

The critical insight is that puncture resistance isn't about making the entire sole out of an impenetrable material. Instead, it relies on a dedicated, specialized plate strategically placed within the sole's construction to provide a formidable barrier against hazards underfoot.

The Core Protective Mechanism: The Puncture Plate

Strategic Placement

The protective plate is situated in the midsole of the footwear. This location is crucial because it is protected from external wear by the outsole, while the insole and footbed above it ensure comfort for the wearer.

This internal placement means the protective feature doesn't interfere with the shoe's tread or grip but is perfectly positioned to intercept any object that pierces the outer sole.

How it Defends the Foot

The function is straightforward but highly effective. When you step on a sharp object like a nail, it may penetrate the rubber outsole.

However, upon reaching the midsole, the object's point makes contact with the hard, resistant plate. The plate distributes the force and physically blocks the object from traveling any further, keeping your foot safe.

Key Materials Used for Protection

Steel Plates

Steel is the traditional material used for puncture-resistant plates. It offers exceptional resistance to penetration and is a proven, reliable technology.

These plates provide a very high level of protection and are often found in heavy-duty industrial and construction footwear.

Composite Plates

Modern footwear increasingly uses composite plates, which can be made from materials like Aramid fibers (such as Kevlar) or other advanced, non-metallic ballistic fabrics.

These plates are engineered to meet the same safety standards as steel but offer different performance characteristics.

Understanding the Trade-offs: Steel vs. Composite

Steel: The Traditional Standard

Steel plates are extremely durable and often more cost-effective. However, they are also heavier, conduct heat and cold, and will set off metal detectors. This rigidity can sometimes reduce the overall flexibility of the shoe.

Composite: The Modern Alternative

Composite plates are significantly lighter and more flexible than steel, which can lead to greater comfort over a long workday. They are also non-conductive, making them ideal for extreme temperatures, and they won't trigger metal detectors.

A Note on Safety Toes

It is critical to distinguish between puncture resistance and safety toes. A puncture-resistant plate protects the bottom of the foot from objects penetrating the sole.

A safety toe, whether steel or composite, protects the toes at the front of the foot from impact and compression injuries from above. A truly protective work boot will often incorporate both features.

Making the Right Choice for Your Goal

Selecting the right material depends entirely on your specific work environment and personal needs.

- If your primary focus is maximum protection and cost-effectiveness: A steel plate is the proven, industry-standard choice for demanding environments like demolition or construction.

- If your primary focus is all-day comfort, flexibility, and working in varied temperatures: A composite plate is the superior option due to its light weight and non-conductive properties.

- If you work in high-security areas with metal detectors: Composite plates are essential to avoid logistical hassles without compromising safety.

Understanding this core technology empowers you to select footwear that provides a critical last line of defense against workplace hazards.

Summary Table:

| Feature | Steel Plate | Composite Plate |

|---|---|---|

| Protection Level | Maximum, industry standard | Meets safety standards |

| Weight | Heavier | Lighter, more flexible |

| Conductivity | Conducts heat/cold | Non-conductive |

| Metal Detectors | Will trigger | Will not trigger |

| Best For | Heavy-duty industrial work | All-day comfort, varied temperatures |

Need reliable, high-quality puncture-resistant footwear? As a large-scale manufacturer, 3515 produces a comprehensive range of safety boots and shoes for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of puncture-resistant footwear, ensuring your workforce is protected with durable, comfortable, and compliant solutions. Contact us today to discuss your specific needs and get a quote!

Visual Guide

Related Products

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Heavy-Duty Waterproof Nubuck Safety Boots Safety Shoes for Bulk Supply

- Wholesale Safety Boots Manufacturer for Custom & Private Label Orders

People Also Ask

- What additional safety features do steel toe work boots often include? Beyond the Steel Toe Cap

- What safety features can some gumboots have? Essential PPE for Hazardous Work Environments

- What is the overall recommendation regarding steel toe boot usage? Essential for Maximum Protection

- What are the key considerations when choosing safety boots? Match Hazards to Features for Maximum Protection

- Do steel toe boots increase the risk of trips and falls? How Quality Design Enhances Stability