The definitive answer is that PVC rain boots are best suited for general-purpose, light-duty activities in moderate climates where basic, affordable waterproof protection is the primary goal. Their use is defined as much by their strengths—low cost and ease of maintenance—as by their limitations in cold weather and demanding environments.

While PVC boots provide an excellent economical and lightweight waterproof solution, their ideal use case is dictated by their material limitations. Understanding these trade-offs is crucial for avoiding poor performance in cold or high-stress conditions.

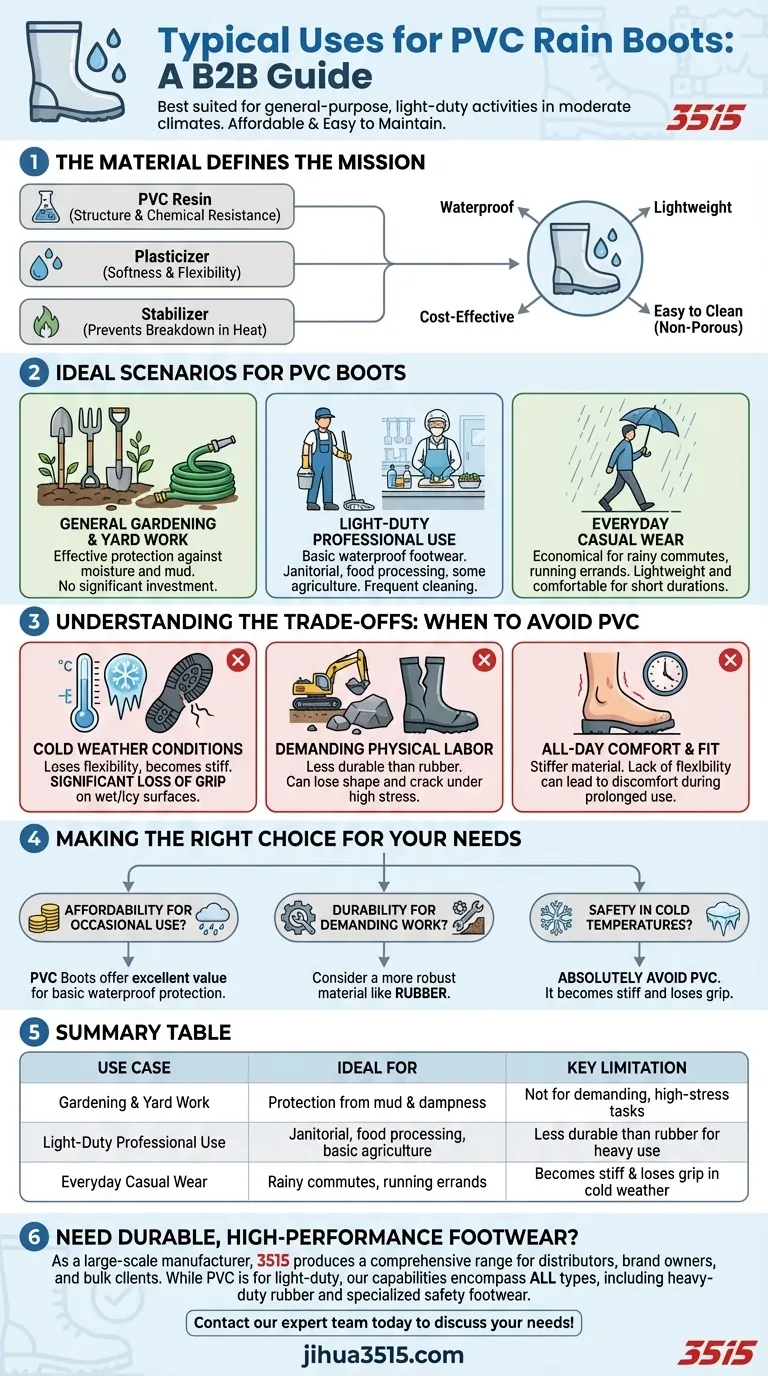

The Material Defines the Mission

To understand why PVC boots are used for specific tasks, we must first look at their composition. They are not simply "plastic" but a carefully formulated material with distinct properties.

The Core Components

PVC boots are primarily made from polyvinyl chloride (PVC) resin, which provides the fundamental structure and chemical resistance.

This resin is mixed with a plasticizer to increase softness and flexibility, along with a stabilizer to prevent the material from breaking down during the high-heat manufacturing process.

Other additives, like colorants or fillers, can be included to meet specific design requirements.

The Resulting Characteristics

This formulation results in a boot that is inherently waterproof, lightweight, and cost-effective to produce.

Because the material is non-porous and smooth, PVC boots are also exceptionally easy to clean and maintain, making them a practical choice.

Ideal Scenarios for PVC Boots

The properties of PVC make it a perfect fit for a clear set of applications where its benefits shine and its weaknesses are not a factor.

General Gardening and Yard Work

For tasks like working in a damp garden, mowing a wet lawn, or washing a car, PVC boots provide effective protection against moisture and mud without a significant investment.

Light-Duty Professional Use

They are a common choice in jobs requiring basic waterproof footwear but not extreme durability. This includes certain agricultural tasks, janitorial work, and food processing environments where frequent cleaning is necessary.

Everyday Casual Wear

As an economical option for rainy day commutes or running errands, PVC boots keep your feet dry for short durations. Their lightweight nature makes them more comfortable for casual walking than heavier, more rugged boots.

Understanding the Trade-offs: When to Avoid PVC

The same material properties that make PVC boots ideal for some situations make them unsuitable for others. This is not a failure of the boot, but a limitation of the material itself.

Cold Weather Conditions

The most significant limitation of PVC is its performance in the cold. As temperatures drop, the material loses flexibility and becomes stiff, which can be uncomfortable and restrictive.

Crucially, the sole also hardens, leading to a significant loss of grip on wet or icy surfaces, creating a potential safety hazard.

Demanding Physical Labor

While suitable for light work, standard PVC boots are less durable than rubber counterparts. Over time and with heavy use, they can lose their original shape and are more prone to cracking or splitting under high stress.

All-Day Comfort and Fit

PVC is generally a stiffer material than rubber. For individuals on their feet all day, this lack of flexibility can lead to less comfort compared to boots made from more pliable materials that conform better to the foot.

Making the Right Choice for Your Needs

Selecting the right boot requires matching the tool to the task. PVC's value is in its practicality for specific, non-demanding environments.

- If your primary focus is affordability for occasional use: PVC boots offer excellent value for basic waterproof protection in moderate weather.

- If your primary focus is durability for demanding work: You should consider a more robust and flexible material like rubber, as PVC can lose shape and break down under stress.

- If your primary focus is safety in cold temperatures: Absolutely avoid PVC, as it becomes stiff and loses its grip, making it unsuitable for snow or ice.

Ultimately, choosing the right boot means matching the material's inherent properties to the demands of your specific environment.

Summary Table:

| Use Case | Ideal For | Key Limitation |

|---|---|---|

| Gardening & Yard Work | Protection from mud and dampness | Not for demanding, high-stress tasks |

| Light-Duty Professional Use | Janitorial, food processing, basic agriculture | Less durable than rubber for heavy use |

| Everyday Casual Wear | Rainy commutes, running errands | Becomes stiff and loses grip in cold weather |

Need Durable, High-Performance Footwear for Your Business?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. While PVC boots are perfect for light-duty applications, our production capabilities encompass all types of shoes and boots, including heavy-duty rubber and specialized safety footwear designed for demanding environments and extreme conditions.

Let us help you find or create the perfect footwear solution for your market. Contact our expert team today to discuss your needs!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

People Also Ask

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- How do industrial safety shoes provide protection for personnel? Safeguard Your Team from Heavy Crane Hazards

- What are the differences between steel toe, composite toe, and alloy toe Wellington boots? Choose the Right Safety Toe for Your Job

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries