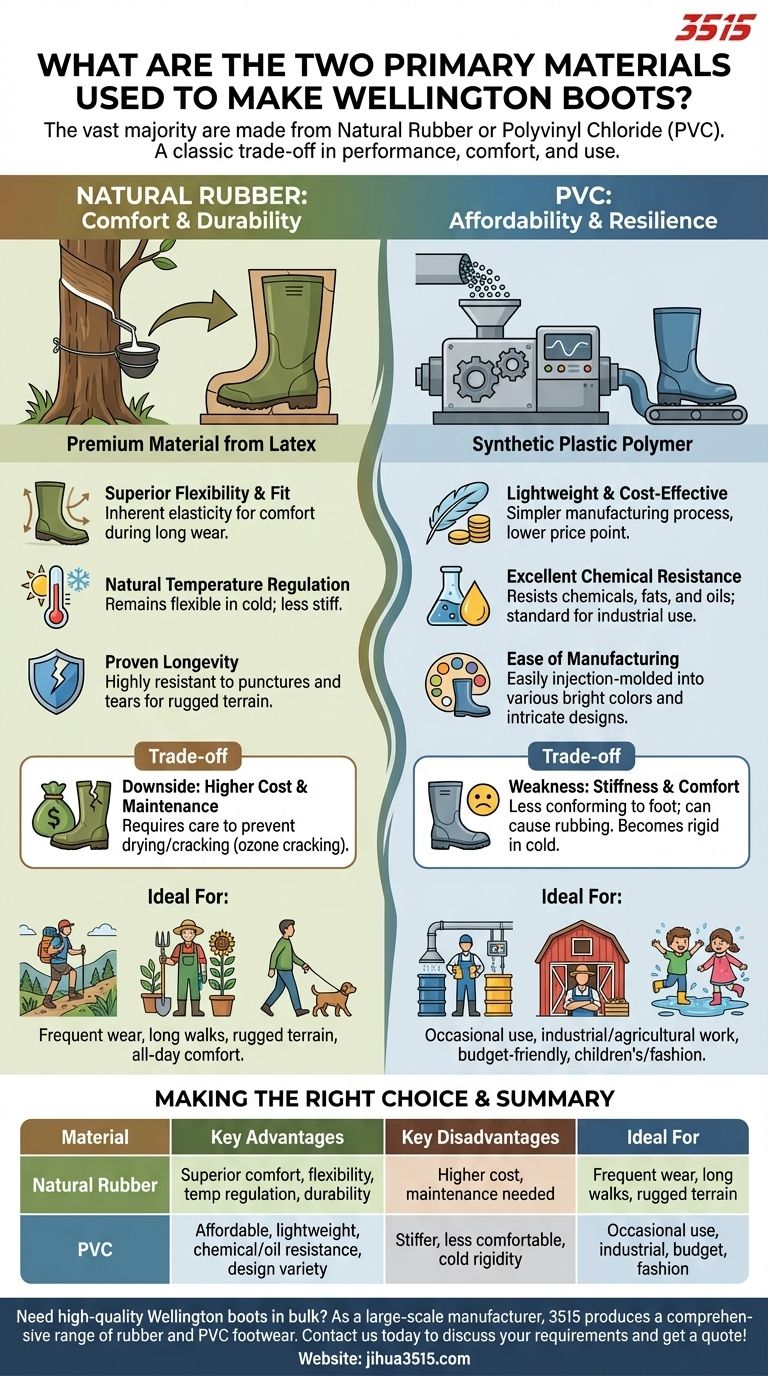

The vast majority of Wellington boots are made from one of two core materials: natural rubber or a synthetic plastic known as Polyvinyl Chloride (PVC). While they may look similar, their performance, comfort, and ideal use cases are fundamentally different.

Your choice between rubber and PVC is a classic trade-off. Natural rubber offers superior comfort and durability for frequent wear, while PVC provides a lighter, more affordable, and highly chemical-resistant option for occasional or specialized use.

The Case for Natural Rubber: Comfort and Durability

Natural rubber has been the traditional material for Wellington boots for a reason. It is a premium material derived from the latex of the rubber tree, offering a distinct set of advantages for the wearer.

Superior Flexibility and Fit

Because it is a natural material, rubber has an inherent elasticity. This allows the boot to flex with your foot, providing significantly more comfort during long walks or periods of extended wear.

Natural Temperature Regulation

Rubber performs better across a wider range of temperatures than PVC. It is less likely to become stiff and brittle in the cold, maintaining its protective flexibility when you need it most.

Proven Longevity

High-quality rubber boots are known for their durability. The material is naturally resistant to punctures and tears, making it an excellent choice for navigating rugged terrain or demanding garden work.

The Case for PVC: Affordability and Resilience

PVC, or polyvinyl chloride, is a synthetic plastic polymer. Its primary advantages stem from its manufacturing process, which makes it a highly practical and cost-effective alternative to rubber.

Lightweight and Cost-Effective

The manufacturing process for PVC is simpler and less expensive than that for natural rubber. This translates directly to a lower price point and a lighter boot, making them an accessible option for many users.

Excellent Chemical Resistance

PVC's synthetic nature makes it highly resistant to chemicals, fats, and oils. This is why PVC boots are often the standard choice in industrial, agricultural, or food processing environments where exposure is common.

Ease of Manufacturing

PVC can be easily injection-molded into a vast array of bright colors and intricate designs. This allows for more variety in style and makes it a popular choice for fashion-oriented or children's boots.

Understanding the Trade-offs

Neither material is universally superior; the right choice depends entirely on your intended use. Understanding their inherent weaknesses is key to avoiding disappointment.

Rubber's Downside: Cost and Maintenance

The primary drawbacks of natural rubber are its higher cost and the need for occasional maintenance. Over time, if not cared for, rubber can dry out and crack, a condition known as ozone cracking.

PVC's Weakness: Stiffness and Comfort

The main compromise with PVC is comfort. The material is inherently stiffer and does not conform to the foot as well as rubber, which can lead to rubbing and discomfort on longer walks. It can also become very rigid in cold weather.

Making the Right Choice for Your Needs

To select the right boot, you must first define its primary purpose.

- If your primary focus is frequent use, long walks, or all-day comfort: Choose natural rubber for its superior flexibility and fit.

- If your primary focus is affordability, occasional use, or work with chemicals: Choose PVC for its low cost and high material resistance.

- If your primary focus is general gardening or rainy-day commuting: Either material can work, but PVC often provides the most cost-effective and lightweight solution.

Understanding the material is the first step to finding a boot that serves you well for years to come.

Summary Table:

| Material | Key Advantages | Key Disadvantages | Ideal For |

|---|---|---|---|

| Natural Rubber | Superior comfort & flexibility, Better temperature regulation, High durability & puncture resistance | Higher cost, Requires maintenance to prevent drying/cracking | Frequent wear, long walks, rugged terrain, all-day comfort |

| PVC (Polyvinyl Chloride) | More affordable & lightweight, Excellent chemical, oil, & fat resistance, Easy to mold into various colors/designs | Stiffer, less comfortable for long periods, Can become rigid in cold weather | Occasional use, industrial/agricultural work, budget-friendly options, children's/fashion boots |

Need high-quality Wellington boots in bulk?

As a large-scale manufacturer, 3515 produces a comprehensive range of rubber and PVC footwear for distributors, brand owners, and bulk clients. Whether you need the premium comfort of natural rubber or the resilient affordability of PVC, we have the production capabilities and expertise to meet your specifications.

Contact our team today to discuss your requirements and get a quote!

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

- Wholesale Waterproof Tactical Boots Custom Suede & High-Traction Soles

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

People Also Ask

- How are rubber boots positioned between function and fashion? The Ultimate Guide to Versatile Footwear

- How can children's feet be measured for Wellington boots? A Step-by-Step Guide for the Perfect Fit

- How can wellies be made sustainable? Shift to Natural Rubber & Ethical Production

- What should be done if someone is in-between sizes when selecting Wellington boots? Size Up for the Perfect Fit

- What are the benefits of wearing wellington boots in construction, agricultural, and chemical work environments?

- What finishing touches are applied to gumboots before packaging? Ensure Quality and Durability

- What is the proper method for cleaning wellies? Preserve Your Boots for Years to Come

- What are the benefits of short ankle Wellington boots? Lightweight, Versatile & All-Day Comfort