In hazardous work environments, the primary benefits of wellington boots are their seamless waterproof design, extended coverage up the lower leg, and durable material construction that protects against water, mud, and specific chemicals. This ensures workers' feet remain dry, clean, and shielded from common workplace hazards.

While all wellington boots provide essential waterproofing, their true value in industrial settings depends on selecting the right material—like affordable PVC or flexible rubber—to match the specific physical and chemical hazards of the job.

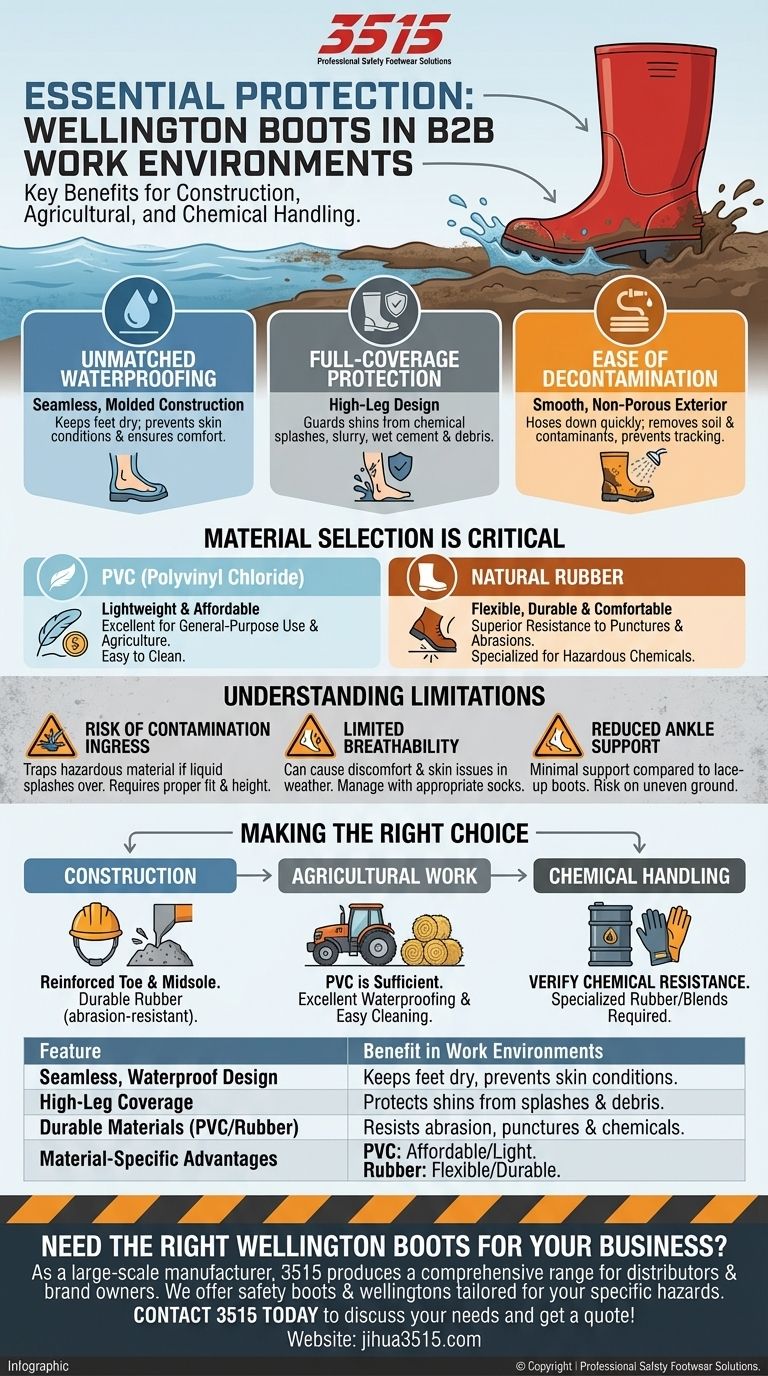

The Core Protective Functions of Wellington Boots

Wellington boots are a specialized tool designed for specific environmental challenges. Their value comes from a few core design principles that directly address the risks found in construction, agriculture, and chemical handling.

Unmatched Waterproofing

The seamless, molded construction of a wellington boot creates an impermeable barrier. This is critical for keeping feet dry when wading through water, mud, or wet concrete, which helps prevent skin conditions and maintains worker comfort.

Full-Coverage Protection

Unlike standard work boots, the high-leg design protects the shin and lower leg. This is vital for guarding against splashes from chemicals, slurry, or wet cement, as well as protecting from low-level scuffs and impacts from debris.

Ease of Decontamination

The smooth, non-porous exterior of rubber or PVC boots makes them exceptionally easy to clean and decontaminate. Hosing them down can quickly remove soil, chemicals, and other contaminants before they can be tracked elsewhere or cause prolonged skin contact.

Material Selection is Critical

The specific material of the boot dictates its performance, cost, and ideal use case. The two most common options have distinct advantages.

PVC (Polyvinyl Chloride)

PVC wellingtons are lightweight and highly affordable, making them a popular choice for general-purpose use. Their excellent resistance to water and many common agricultural chemicals makes them a practical option.

They are also very easy to clean and maintain, suiting environments like farms or food processing facilities where hygiene is a priority.

Natural Rubber

Boots made from natural rubber are typically more flexible and comfortable for long periods of wear. Rubber offers superior durability against punctures and abrasions.

Many specialized rubber compounds also provide enhanced resistance to a wider range of oils, fats, and industrial chemicals, making them a necessity for more hazardous environments.

Understanding the Trade-offs and Limitations

While highly effective, wellington boots are not a universal solution. Understanding their inherent limitations is key to using them safely.

Risk of Contamination Ingress

The most significant risk is that liquids can splash over the top of the boot. If this happens, the boot becomes a container, trapping the hazardous material against the skin. A proper fit and appropriate boot height are critical to mitigate this.

Limited Breathability

The same feature that makes wellingtons waterproof also makes them non-breathable. In hot weather, this can lead to significant discomfort and sweating, which can cause skin issues if not managed with appropriate socks.

Reduced Ankle Support

The pull-on, unstructured design of most wellington boots offers minimal ankle support compared to lace-up safety boots. This can increase the risk of sprains and strains when walking on highly uneven or unstable ground.

Making the Right Choice for Your Environment

Your specific work environment dictates the best choice. Use these guidelines to select the right protection.

- If your primary focus is Construction: Prioritize boots with a reinforced toe cap and midsole, and choose a durable rubber compound that can withstand abrasion from gravel and wet concrete.

- If your primary focus is Agricultural Work: A PVC boot is often sufficient, providing excellent waterproofing and ease of cleaning for dealing with mud and slurry at an affordable price point.

- If your primary focus is Chemical Handling: You must verify the boot material's chemical resistance chart against the specific substances you work with; specialized rubber or blended compounds are often required.

Ultimately, choosing the right wellington boot is about matching the specific features of the boot to the real-world hazards you face.

Summary Table:

| Feature | Benefit in Work Environments |

|---|---|

| Seamless, Waterproof Design | Keeps feet dry in water, mud, and wet concrete, preventing skin conditions. |

| High-Leg Coverage | Protects shins and lower legs from chemical splashes, slurry, and debris. |

| Durable Materials (PVC/Rubber) | Resists abrasion, punctures, and specific chemicals; easy to decontaminate. |

| Material-Specific Advantages | PVC: Affordable & lightweight. Rubber: Flexible, durable & superior chemical resistance. |

Need the right wellington boots for your business?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and wellingtons tailored for construction, agriculture, and chemical handling.

We can help you source the perfect protective footwear that meets your specific hazard requirements and budget.

Contact 3515 today to discuss your needs and get a quote!

Visual Guide

Related Products

- Factory Direct Wholesale Rain Boots Durable Waterproof & Fully Customizable

- Premium KPU Injection Athletic Style Safety Shoes

- Wholesale Anti-Smash & Puncture-Proof Safety Shoes Custom Manufacturing for Brands

- Premium High-Cut Waterproof Safety Boots Manufacturing & Wholesale Solutions

- Factory-Direct Wholesale Canvas Boots with High-Traction Rubber Soles

People Also Ask

- What are the key differences between neoprene-lined and regular Wellington boots? Choose the Right Boot for Any Climate

- Why is PVC resin important in making rain boots? The Key to Durability & Performance

- How should one measure their feet for the best fit in wellies? Get a Perfect, Pain-Free Fit Every Time

- How can wellies be styled with skirts and tights? Master the Perfect Layered Look

- What is the history of Wellington boots? From Duke's Design to Global Icon

- How can common problems like cracking, mould, or discolouration in wellies be prevented? A Simple Care Routine Guide

- What are the limitations of rain boots in certain climates? Find the Right Footwear for Your Weather

- How can waterproof shoes be maintained for long-term use? Extend the Lifespan of Your Footwear