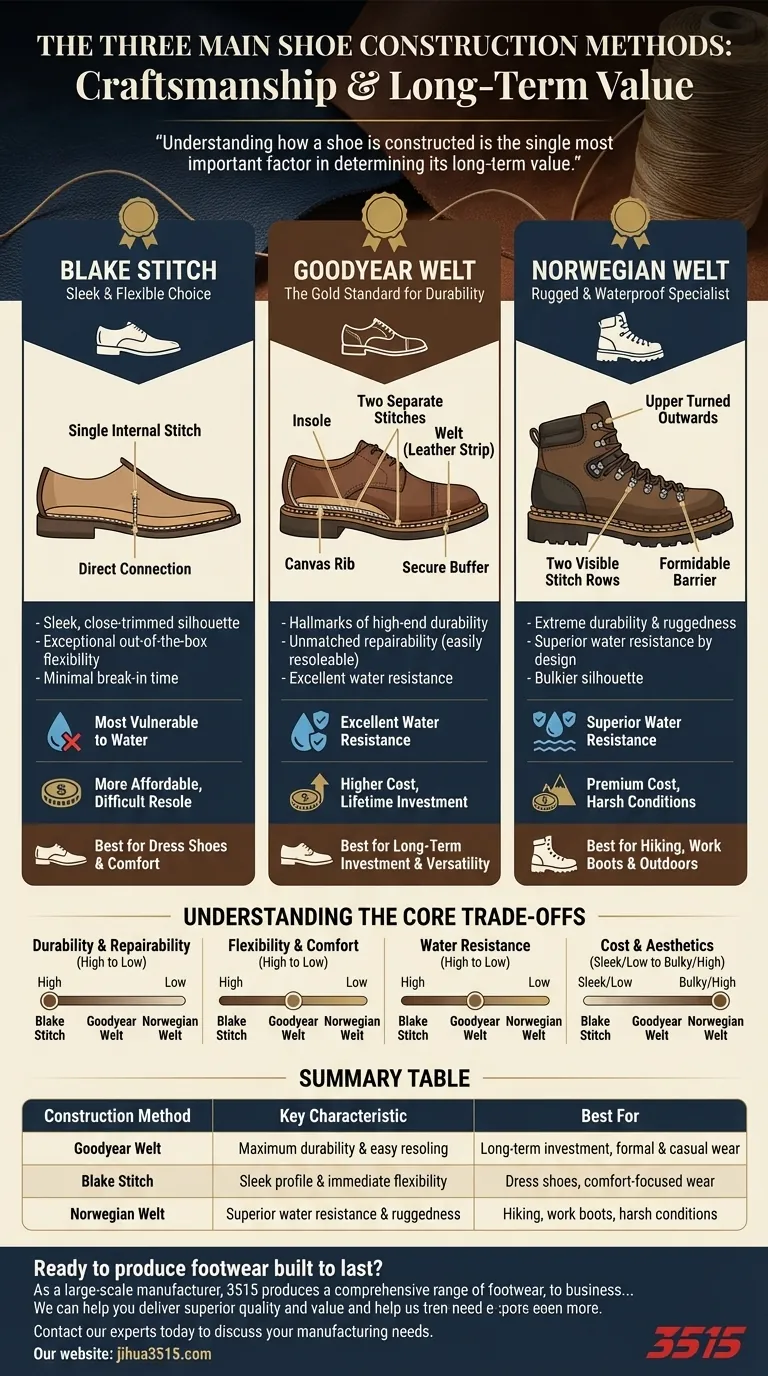

The three principal methods of high-quality shoe construction are the Goodyear welt, the Blake stitch, and the Norwegian welt. Each method involves stitching the shoe's upper to its sole, but the specific technique dramatically impacts the final product's durability, flexibility, water resistance, and repairability. While simpler cemented (glued) construction is common in sneakers and fast fashion, these stitched methods define true craftsmanship.

Understanding how a shoe is constructed is the single most important factor in determining its long-term value. The choice between these methods is a direct trade-off between flexibility, durability, and the ease of replacing the sole to extend the shoe's life.

The Spectrum of Stitched Construction

Before diving into the premier methods, it's crucial to acknowledge the most common construction in modern footwear: cementing. In this process, the sole is simply glued to the upper with a strong adhesive. It's fast, inexpensive, and allows for lightweight, flexible designs, but the bond is permanent. Once the sole wears out, the shoe is typically finished.

Stitched methods represent a significant step up in quality and longevity.

Blake Stitch: The Sleek & Flexible Choice

The Blake stitch is an elegant and direct method of construction. A single stitch runs from the inside of the shoe, through the insole, the upper, and directly into the outsole.

This internal stitch creates a shoe with a very sleek, close-trimmed silhouette because there are no external stitches on the edge of the sole.

The direct connection also results in a shoe that is exceptionally flexible and comfortable right out of the box, requiring minimal break-in time.

Goodyear Welt: The Gold Standard for Durability

The Goodyear welt is a more complex, labor-intensive, and robust method. It involves two separate stitches, making it the hallmark of high-end, durable footwear.

First, a canvas rib is attached to the insole. The upper is then stitched to a leather strip called the welt, which runs around the outside perimeter of the shoe. Second, a separate, heavy-duty stitch attaches this welt to the outsole.

This two-level stitching creates a secure, water-resistant buffer between the insole and the outsole. Most importantly, it allows the outsole to be removed and replaced by a cobbler without disturbing the shoe's upper.

Norwegian Welt: The Rugged & Waterproof Specialist

The Norwegian welt (or storm welt) is an even more robust construction, prized for its extreme durability and water resistance. It is easily identified by two visible rows of stitching.

Similar to a Goodyear welt, it uses an external welt. However, the shoe's upper is turned outwards and stitched down to the midsole or outsole, creating a formidable barrier against the elements.

This method is most commonly found on heavy-duty work boots, hiking boots, and country footwear designed to withstand harsh conditions.

Understanding the Core Trade-offs

Choosing between these constructions is not about finding the "best" one, but the one that best suits your needs. Each method presents a different balance of key characteristics.

Durability & Repairability

The Goodyear welt is the undisputed champion of repairability. A skilled cobbler can resole Goodyear-welted shoes multiple times, dramatically extending their lifespan. The Norwegian welt is similarly durable, while the Blake stitch is more difficult—and sometimes impossible—to resole.

Flexibility & Comfort

A Blake-stitched shoe offers superior out-of-the-box flexibility due to its simpler, more direct construction. Goodyear and Norwegian welted shoes are much stiffer initially and require a significant break-in period to mold to your foot.

Water Resistance

The Norwegian welt is the most water-resistant by design, with its outward-turned upper creating a seal. The Goodyear welt offers excellent water resistance due to the welt acting as a buffer. The Blake stitch is the most vulnerable, as the single stitch can wick moisture directly into the insole.

Cost & Aesthetics

Goodyear and Norwegian welts are more labor-intensive and use more materials, making them the most expensive options. They also result in a slightly bulkier silhouette. The Blake stitch allows for a much more trim, close-cut sole, often seen as more elegant in formal dress shoes.

Making the Right Choice for Your Goal

Ultimately, the ideal construction method depends entirely on your priority.

- If your primary focus is a sleek profile and immediate comfort for dress shoes: A Blake-stitched shoe offers an excellent balance of quality and flexibility.

- If your primary focus is long-term investment and maximum durability: The Goodyear welt is the definitive standard for its unmatched repairability.

- If your primary focus is uncompromising water resistance for rugged outdoor use: The Norwegian welt provides the most robust protection available.

By understanding the principles behind how your shoes are made, you gain the power to invest in footwear that truly serves your needs.

Summary Table:

| Construction Method | Key Characteristic | Best For |

|---|---|---|

| Goodyear Welt | Maximum durability & easy resoling | Long-term investment, formal & casual wear |

| Blake Stitch | Sleek profile & immediate flexibility | Dress shoes, comfort-focused wear |

| Norwegian Welt | Superior water resistance & ruggedness | Hiking, work boots, harsh conditions |

Ready to produce footwear built to last?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of shoes and boots, including the durable Goodyear welt, the sleek Blake stitch, and the rugged Norwegian welt construction.

We can help you deliver superior quality and value to your customers. Contact our experts today to discuss your manufacturing needs.

Visual Guide

Related Products

- Wholesale Breathable Training Shoes Custom Athletic Footwear Manufacturer

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Lightweight Breathable Training Shoes for Wholesale & Custom OEM Manufacturing

- Wholesale Durable & Breathable Training Shoes for Custom Brands

- Wholesale Breathable & Cushioned Training Shoes Custom Factory Production

People Also Ask

- What is high-tech 'air' mesh, and how is it used in footwear? The Key to Cool, Lightweight Shoes

- What are the features of cross training shoes? Master Versatile Performance for Your Workouts

- What are the benefits of athletic-style work shoes? Boost Comfort and Safety for Your Team

- What are the benefits of breathable mesh in shoe design? Enhance Comfort and Performance

- How do athletic shoes with non-slip features differ from regular ones? Discover the Grip Advantage