Choosing the right work boot material is a critical decision that balances the specific hazards of your environment, the physical demands of your tasks, and the necessity of all-day comfort. The best choice is not a single material, but a combination of materials in the upper, toe, and sole that work together to provide tailored protection and support.

The ideal work boot is a system of materials, not a single component. Your goal is to match the boot's entire construction—from the upper leather to the protective toe cap to the outsole rubber—directly to the specific risks and conditions of your job.

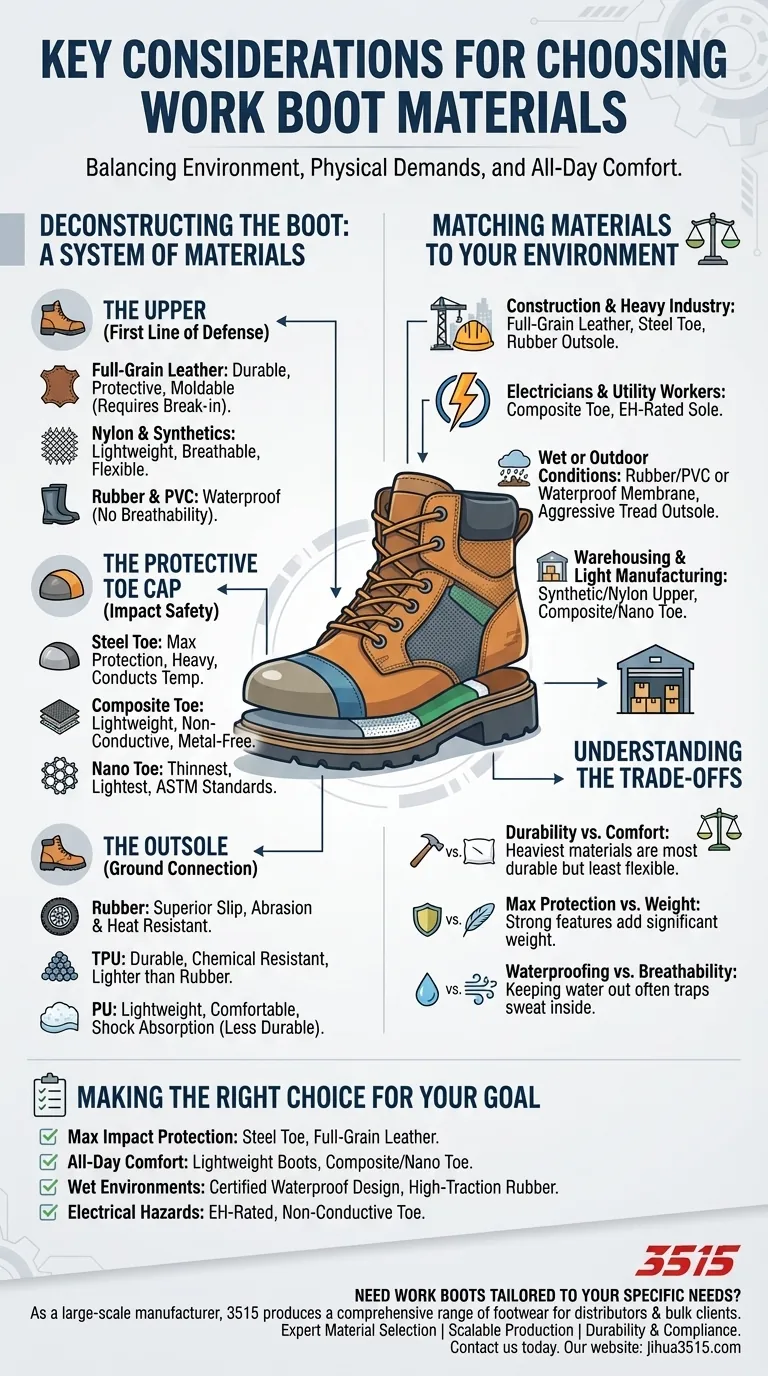

Deconstructing the Boot: A System of Materials

A work boot is more than just leather. Understanding how its different parts function is the first step in making an informed choice. Each component uses specific materials designed for a distinct purpose.

The Upper: Your First Line of Defense

The upper is the main body of the boot, covering the foot. Its material dictates breathability, water resistance, and overall durability.

- Full-Grain Leather: This is the gold standard for durability and protection. It's tough, breathable, and conforms to your foot over time but requires a break-in period and maintenance.

- Nylon & Synthetics: These materials offer excellent flexibility and breathability and are much lighter than leather. They are often used in combination with leather to reduce weight and improve comfort.

- Rubber & PVC: Completely waterproof, these materials are essential for extremely wet conditions. Their primary trade-off is a complete lack of breathability.

The Protective Toe Cap: Impact and Compression Safety

This is the most critical safety feature for many trades. The material used affects the boot's weight, conductivity, and level of protection.

- Steel Toe: The traditional choice, offering maximum protection against impact and compression. Steel toes are heavy and conduct temperature.

- Composite Toe: Made from non-metal materials like Kevlar, carbon fiber, or plastic. They are lighter than steel, don't conduct electricity or temperature, and are ideal for metal-free work environments.

- Nano Toe: The most modern option, using carbon nanotubes to create the thinnest and lightest safety toe available while still meeting ASTM safety standards.

The Outsole: Your Connection to the Ground

The outsole determines the boot's traction and resistance to chemicals, heat, and abrasion.

- Rubber: Offers superior slip resistance, especially on wet or oily surfaces. It is also highly resistant to abrasion.

- TPU (Thermoplastic Polyurethane): A very durable, long-wearing material that resists chemicals and abrasion. It is often lighter than rubber.

- PU (Polyurethane): Valued for being lightweight and comfortable, providing excellent shock absorption. It is less durable than rubber or TPU.

Matching Materials to Your Work Environment

The abstract qualities of materials only matter in the context of your job site. Your daily environment should be the primary guide for your decision.

For Construction and Heavy Industry

Your environment demands maximum durability and impact protection. Prioritize boots with full-grain leather uppers for abrasion resistance and steel toes for a high level of certified impact protection. A thick rubber outsole is essential for traction.

For Electricians and Utility Workers

Protection from electrical current is non-negotiable. You must select a boot with a non-conductive composite toe and a sole that is explicitly Electrical Hazard (EH) rated.

For Wet or Outdoor Conditions

Waterproofing is key. Look for boots made with rubber or PVC or those featuring a dedicated waterproof membrane inside a leather or synthetic upper. An outsole with a deep, aggressive tread pattern is critical for maintaining grip on mud, water, or uneven terrain.

For Warehousing and Light Manufacturing

Long hours on concrete floors make comfort and low weight paramount. A boot with synthetic or nylon uppers will be more breathable and flexible. A composite or nano toe will reduce fatigue compared to a heavier steel toe.

Understanding the Trade-offs

There is no single perfect work boot material. Every choice involves a compromise, and understanding these trade-offs is crucial for selecting the right boot for your needs.

Durability vs. Comfort

The most durable materials, like thick full-grain leather and steel, are often the heaviest and least flexible. Lighter, more comfortable materials like nylon may not withstand the same level of abuse.

Maximum Protection vs. Weight

Features like steel toes, puncture-resistant plates, and thick rubber outsoles offer incredible safety but add significant weight. This can lead to fatigue over a long shift. Composite materials offer a lighter alternative but may come at a higher cost.

Waterproofing vs. Breathability

Truly waterproof materials like rubber and PVC will keep water out, but they also trap sweat inside. Materials that breathe well, like nylon mesh or standard leather, offer poor protection in genuinely wet conditions.

Making the Right Choice for Your Goal

Select your boot by prioritizing the single most important factor for your daily work.

- If your primary focus is maximum impact protection: Prioritize boots with steel toe caps and tough, full-grain leather uppers.

- If your primary focus is all-day comfort and reduced fatigue: Look for lightweight boots with composite or nano toes and flexible synthetic uppers.

- If your primary focus is working in wet or slippery environments: Choose boots with a certified waterproof design and a high-traction rubber outsole.

- If your primary focus is protection from electrical hazards: Ensure the boot is explicitly EH-rated, a non-negotiable safety certification.

By systematically matching the boot's material system to your specific needs, you transform a simple purchase into a vital investment in your safety and daily well-being.

Summary Table:

| Material Component | Key Options | Best For |

|---|---|---|

| Upper | Full-Grain Leather, Nylon/Synthetics, Rubber/PVC | Durability, Breathability, Waterproofing |

| Toe Cap | Steel, Composite, Nano | Impact Protection, Lightweight, Electrical Safety |

| Outsole | Rubber, TPU, PU | Slip Resistance, Chemical Resistance, Comfort |

Need Work Boots Tailored to Your Specific Needs?

As a large-scale manufacturer, 3515 produces a comprehensive range of footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety and work boots, ensuring the perfect combination of materials for your job's hazards and demands.

We provide:

- Expert Material Selection: We help you choose the right uppers, toe caps, and outsoles for maximum safety and comfort.

- Scalable Production: From large distributor orders to custom-branded solutions, we deliver consistent quality at scale.

- Durability & Compliance: Our boots are built to meet or exceed industry safety standards.

Let's build the perfect boot for your workforce. Contact our team today for a consultation and quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Wholesale Waterproof Safety Boots High Performance Protection for Industrial Markets

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- Puncture-Resistant Velcro Safety Boots for Wholesale & Custom Manufacturing

People Also Ask

- What are the advantages of leather versus synthetic work boots? A Guide to Choosing the Right Material

- Why is choosing the right work boot size important? Protect Your Health and Safety on the Job

- What role do industrial safety shoes and boots play in fire rescue? Pandemic Intervention & PPE Integration Guide

- What is a composite toe work boot? A Lightweight, Non-Metallic Safety Solution

- How do mining boots provide electrical hazard protection? Essential Safety for Electrical Work

- What are water-resistant boots designed for? Keep Your Feet Dry in Everyday Conditions

- When might soft toe work boots be preferred? Prioritize Comfort & Agility for Low-Risk Jobs

- What are the key differences between men's and women's work boots? Ensure Safety & Comfort with the Right Fit