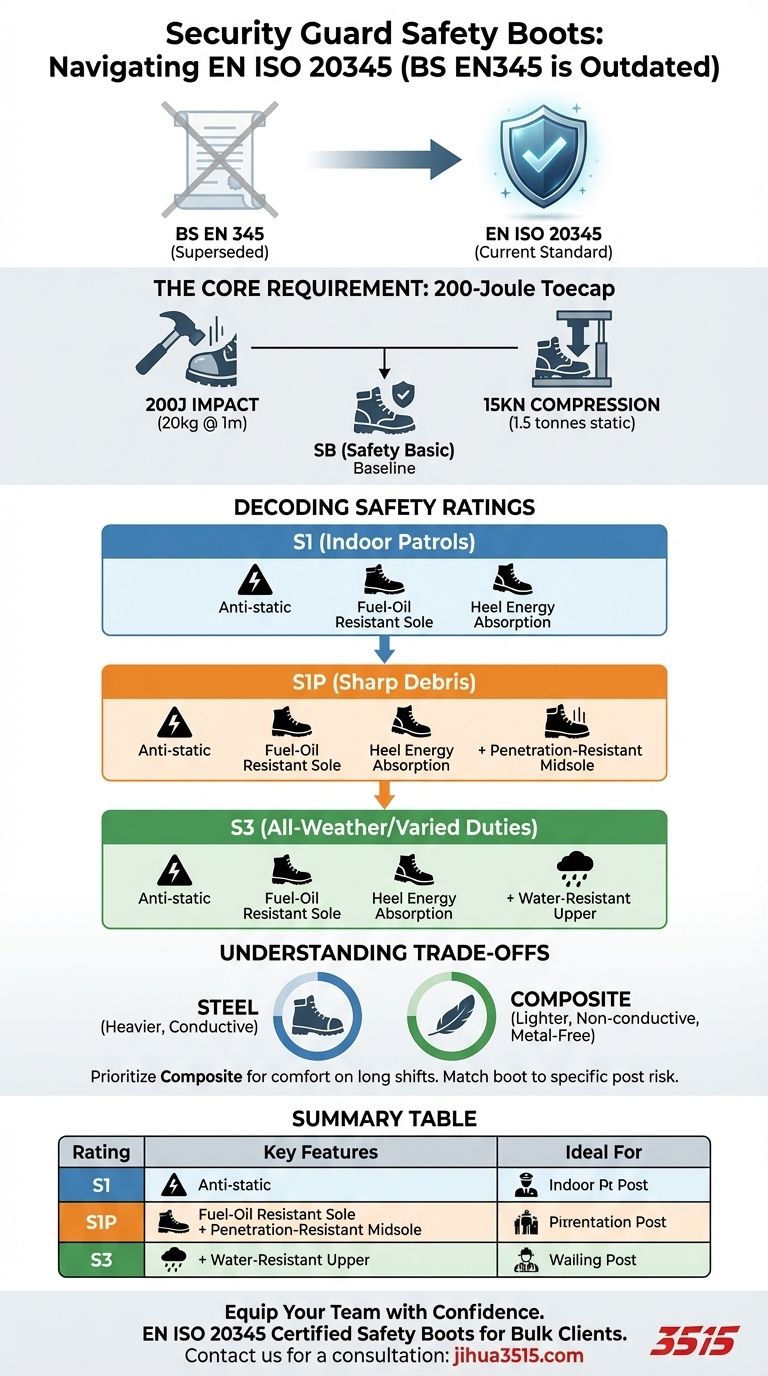

First and foremost, the standard you mentioned, BS EN 345, has been superseded. It was replaced by EN ISO 20345, which is the current European standard for safety footwear. The fundamental requirement of this modern standard is that the boot's protective toecap must withstand a 200-joule impact and a 15 kilonewton (KN) compression force.

The key to selecting the right boot is understanding that EN ISO 20345 is the baseline standard. The specific needs of a security role are met by looking at additional rating codes (like S1, S1P, or S3) that define protections beyond the basic toecap.

From EN 345 to the Modern EN ISO 20345 Standard

The evolution from EN 345 to EN ISO 20345 reflects a more rigorous and standardized approach to safety. While the core principle remains the same—protecting the wearer's feet—the testing and classifications are now more precise.

The Core Requirement: 200-Joule Toe Protection

The heart of the EN ISO 20345 standard is its non-negotiable requirement for a protective toecap. This means the boot has passed two critical tests.

First is the 200-joule impact test, which simulates a 20kg (44 lbs) object being dropped from a height of approximately one meter. Second is the 15KN compression test, which ensures the toecap can withstand roughly 1.5 tonnes of static weight without collapsing.

Beyond the Toecap: A System of Ratings

Simply meeting the toecap requirement earns a boot the most basic rating, SB (Safety Basic). However, the varied duties of a security guard often demand more protection, which is where additional codes become essential.

These codes are added to the SB baseline to denote extra features, creating a clear system for matching a boot to a specific work environment.

Decoding the Safety Ratings for Security Work

Understanding these ratings is the most practical way to choose the right footwear. A security guard's role can shift from quiet indoor patrols to managing unpredictable outdoor situations, making these distinctions critical.

S1: The Standard for Indoor Patrols

An S1 rated boot includes the basic SB toecap protection plus features ideal for long shifts indoors. It is anti-static, has a fuel-oil resistant outsole, and incorporates energy absorption in the heel region to reduce fatigue.

S1P: Protection from Penetration

The S1P rating includes all the features of S1 but adds a penetration-resistant midsole. This is crucial for guards working in environments where sharp objects like nails, glass, or other debris could be underfoot.

S3: The All-Rounder for Varied Duties

For guards who work both indoors and outdoors, an S3 rating is often the most suitable choice. It combines all the features of S1P with a water-resistant upper, providing a comprehensive solution for unpredictable conditions.

Understanding the Trade-offs

Choosing the highest possible rating isn't always the best strategy. The ideal boot balances protection with the practical demands of the job.

Protection vs. Mobility and Comfort

Higher-rated boots, especially fully waterproof ones like S4 or S5, can be heavier and less breathable. For a security guard who needs to be mobile and may spend 12 hours on their feet, a lighter, more comfortable boot like an S1 or S3 is often superior.

Steel vs. Composite Materials

Modern safety boots often use composite materials for toecaps and midsoles instead of traditional steel. These are significantly lighter, do not conduct heat or cold, and won't set off metal detectors, which can be a key advantage in many security settings.

Matching the Boot to the Specific Post

The right boot depends entirely on the assignment. A guard at a corporate headquarters has vastly different needs than one patrolling a construction site or managing crowd control at an outdoor event. A risk assessment of the specific environment is paramount.

Making the Right Choice for Your Goal

- If your primary focus is indoor patrols (e.g., office, retail): An S1-rated boot provides the necessary toe protection, anti-static properties, and all-day comfort.

- If your primary focus is variable environments with potential hazards (e.g., construction sites, event security): An S1P or S3 rating is essential for its added puncture and water resistance.

- If your primary focus is comfort and avoiding fatigue during long shifts: Prioritize boots with composite safety components and enhanced shock-absorbing midsoles, regardless of the specific S-rating.

Ultimately, choosing the right boot means matching the specific safety codes of EN ISO 20345 to the real-world risks of your post.

Summary Table:

| Safety Rating | Key Features | Ideal For |

|---|---|---|

| S1 | Basic toecap, anti-static, fuel-oil resistant sole, heel energy absorption | Indoor patrols, office/retail security |

| S1P | All S1 features + penetration-resistant midsole | Environments with sharp debris (e.g., construction sites) |

| S3 | All S1P features + water-resistant upper | All-weather, indoor/outdoor patrols, event security |

Equip your security team with confidence. As a large-scale manufacturer, 3515 produces a comprehensive range of EN ISO 20345 certified safety boots for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety footwear, ensuring your team gets the perfect balance of protection, comfort, and durability. Contact us today for a consultation and discover how we can meet your specific security footwear needs.

Visual Guide

Related Products

- Premium KPU Injection Athletic Style Safety Shoes

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Customizable Anti-Smash Safety Boots for Wholesale & Private Label Manufacturing

- Premium Wholesale Wheat Nubuck Safety Boot with Rapid Lacing System

People Also Ask

- What is security guard safety boots risk assessment? A Guide to On-Site Hazard Analysis

- What is Goodman and Kruskal’s Gamma for Safety Shoe Analysis? Link Performance Ratings to Wear Frequency

- What type of soles do firefighter boots have and why? Engineered for Extreme Heat & Unmatched Traction

- What is the difference between oil-resistant safety boots and waterproof work boots? Choose the Right Protection

- What is the significance of Functional Reach Test (FRT) benchmarks for balance risks in heavy boots and safety gear?

- What are the advantages of composite toe shoes? Achieve Superior Safety and Comfort

- What role does professional footwear play in protecting workers? Enhance Stability During Trunk Rotation and Bending

- What are the main types of safety toe shoes? Choose the Right Protection for Your Job