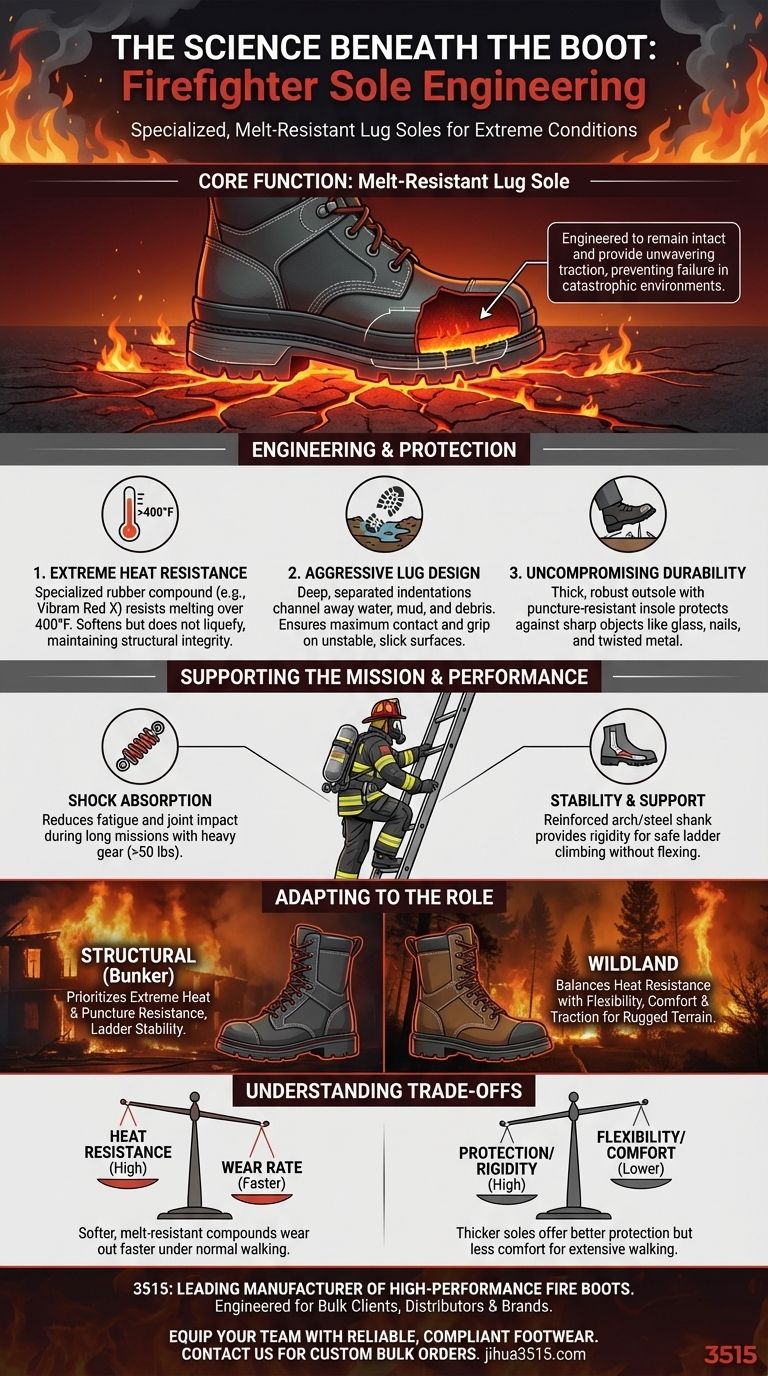

At its core, a firefighter boot uses a specialized, melt-resistant lug sole. This design is not an arbitrary choice; it is a direct and critical response to the extreme heat, unpredictable terrain, and physical demands of firefighting. These soles are engineered from custom rubber compounds designed to remain intact and provide traction even when exposed to conditions that would destroy a standard boot.

The sole of a firefighter boot is a non-negotiable piece of safety equipment. Its primary purpose is to provide unwavering traction and foot protection in environments where failure—due to melting, punctures, or loss of grip—can have catastrophic consequences.

The Engineering Behind the Sole: More Than Just Rubber

A firefighter's boot sole is a system designed to counter multiple threats simultaneously. The materials and design are highly specialized to ensure performance under the worst possible conditions.

The Critical Role of Heat Resistance

The most defining feature of these soles is their ability to withstand extreme heat. They are often made from a custom rubber compound, like the well-known Vibram Red X, which is formulated specifically for this purpose.

This material is engineered to resist melting at temperatures exceeding 400 degrees Fahrenheit. While the sole may soften under intense heat, it is designed not to liquefy, ensuring the boot's structural integrity remains and the firefighter's foot stays protected.

The "Lug" Design for Uncompromising Traction

Firefighting environments are notoriously unstable. Surfaces can be uneven, muddy, covered in water, or slick with chemical residue.

The aggressive lug pattern—the deep, separated indentations on the outsole—is essential for gripping these unpredictable surfaces. This design channels away water and debris to maintain maximum contact and prevent slips and falls.

Durability for a Hostile Environment

The ground at a fire scene is often littered with sharp objects like glass, nails, and twisted metal. The sole must be thick and robust enough to prevent punctures that could cause serious injury.

This is especially critical for bunker boots, which are used in structural firefighting and feature puncture-resistant insoles to complement the tough outsole.

How the Sole Supports the Firefighter's Mission

Beyond pure protection, the boot's sole is designed to enhance a firefighter's performance and reduce the immense physical toll of the job.

Reducing Fatigue with Shock Absorption

Firefighters are on their feet for extended periods, often carrying over 50 pounds of gear. Their boot soles must provide excellent shock absorption to minimize the impact on their joints and reduce overall fatigue during long missions.

Providing Stability for Critical Tasks

A rigid, supportive sole is vital for stability. Many firefighter boots include a reinforced arch or steel shank, which provides the necessary support for safely climbing ladders without the boot flexing and slipping.

Adapting to Different Firefighting Roles

Not all firefighting is the same, and the soles reflect this.

- Bunker or turn-out boots for structural fires prioritize heat and puncture resistance.

- Wildland firefighting boots must balance heat resistance with the flexibility and comfort needed to traverse miles of rugged, natural terrain.

Understanding the Trade-offs

Engineering for such extreme conditions inevitably involves compromises. Understanding these trade-offs reveals the true purpose behind the design.

The Cost of Heat Resistance: Faster Wear

The specialized rubber compounds used for melt resistance are inherently softer than the materials used in standard work boots.

As a result, these soles wear out significantly faster under normal walking conditions. This necessitates more frequent and costly resoling or replacement, a necessary price for uncompromising safety.

Protection vs. Flexibility

A thicker, more rigid sole offers superior protection from punctures and better support on ladders. However, this rigidity can make the boot less comfortable for the extensive walking and hiking required in wildland firefighting.

Boot manufacturers must carefully balance these competing needs based on the boot's intended use.

Making the Right Choice for the Hazard

The specific features of a firefighter's boot sole are directly tied to the primary dangers they will face.

- If the primary focus is structural firefighting: The sole must prioritize extreme heat resistance, puncture protection, and ladder stability above all else.

- If the primary focus is wildland firefighting: The sole must balance heat resistance with durable traction on natural terrain and the shock-absorbing comfort needed for long-distance movement.

- If the primary focus is station duty: The sole is designed for everyday durability and comfort, functioning more like a high-quality work boot without the extreme heat-resistant properties.

Ultimately, the sole of a firefighter's boot is the critical foundation that allows them to move safely and effectively through the most dangerous environments on earth.

Summary Table:

| Feature | Purpose | Material/Design |

|---|---|---|

| Heat Resistance | Withstand extreme heat (>400°F) without melting | Specialized rubber compound (e.g., Vibram Red X) |

| Lug Pattern | Provide traction on unstable, wet, or slick surfaces | Deep, aggressive lugs to channel debris |

| Durability | Protect against punctures from sharp objects | Thick, robust outsole with puncture-resistant insole |

| Shock Absorption | Reduce fatigue during long missions with heavy gear | Engineered for impact absorption and joint support |

| Stability | Ensure safety when climbing ladders | Reinforced arch or steel shank for rigidity |

As a leading manufacturer of high-performance safety footwear, 3515 produces a comprehensive range of firefighter boots for distributors, brand owners, and bulk clients. Our boots are engineered with the specialized soles described above, ensuring maximum protection, durability, and performance in extreme conditions. Whether you need structural firefighting boots with superior heat resistance or wildland boots designed for rugged terrain, we have the production capabilities to meet your exact specifications.

Ready to equip your team with reliable, safety-compliant footwear? Contact us today to discuss your bulk order needs and receive a customized quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

- High Performance Fire-Retardant Waterproof Safety Boots

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium Grain Leather Safety Boots for Bulk Supply

People Also Ask

- What tips help in selecting appropriate safety footwear? A Guide to Matching Hazards & Fit

- What hazards is workplace protective footwear designed to protect against? Ensure Complete Worker Safety

- How does the level of hazmat response affect the choice between leather and rubber boots? Ensure Your Team's Safety

- What key features enhance the functionality of firefighter boots? Built for Extreme Safety & Performance

- What technical protections do professional-grade safety shoes provide? Guard Your Workforce in Palm Oil Factories

- How does the integration of Pressure Sensitive Resistor (FSR) sensors in smart safety shoes help in preventing injury?

- What optional tests can motorcycle boots undergo for CE certification? A Guide to Specialized Performance Ratings

- How do 3D scanning and additive manufacturing transform protective equipment? Experience 100% Anatomical Customization