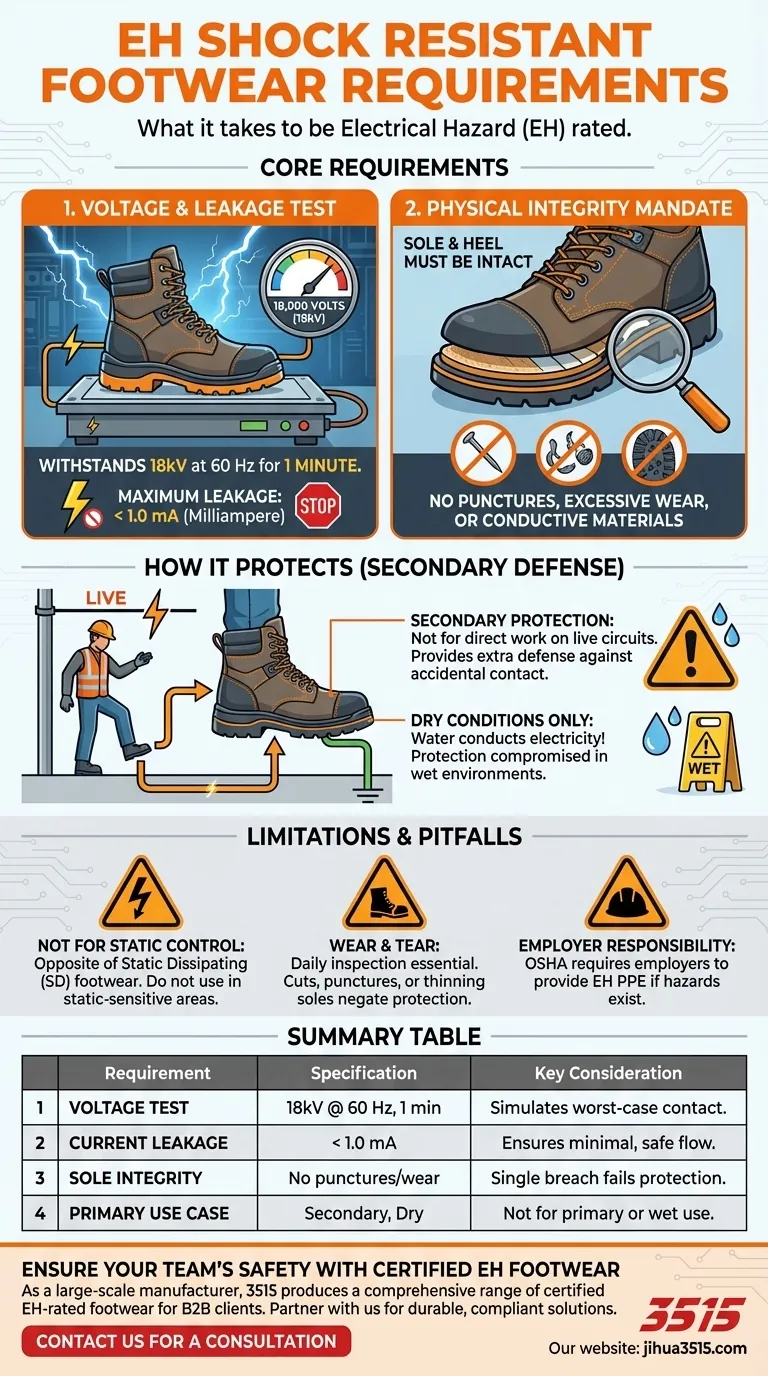

To be officially rated as Electrical Hazard (EH) resistant, footwear must pass a specific lab test: it must withstand 18,000 volts at 60 Hz for one full minute without allowing more than 1.0 milliampere of current to leak through. This protection also depends on the boot's sole and heel remaining intact, free from excessive wear or punctures by conductive objects like nails.

The technical specifications define a boot's potential, but its real-world effectiveness as a secondary defense against electric shock hinges entirely on its physical condition and the environment in which it's used.

Deconstructing the EH Standard

To truly understand EH-rated footwear, we need to look beyond the label and examine the two core requirements that define its protective capabilities.

The Voltage and Leakage Test

The foundational test simulates a worst-case scenario of accidental contact with a high-voltage live circuit. The boot must act as a powerful insulator.

The standard is highly specific:

- Voltage: 18,000 volts (18kV)

- Frequency: 60 Hz (the standard for North American power grids)

- Duration: 1 minute

- Maximum Leakage: 1.0 milliampere

Think of the sole of the boot as a dam holding back a reservoir of electrical pressure. The test proves the dam can hold back an immense amount of pressure for a sustained period with only a minuscule, non-hazardous leak.

The Physical Integrity Mandate

A lab certification is meaningless if the boot fails in the field. The EH rating is only valid as long as the sole and heel provide an unbroken barrier of insulation.

This is why the standard explicitly notes that the sole cannot be significantly worn down or penetrated by any conductive materials. A single nail, metal shaving, or burr embedded in the sole can create a direct path for electricity, completely negating the boot's protective qualities.

How EH Footwear Actually Protects You

Understanding the requirements is the first step. The next is understanding the role EH footwear plays within a broader safety system.

A Secondary Source of Protection

It is critical to understand that EH boots are a secondary source of protection. They are not designed for primary protection against electric shock, such as working directly on live circuits.

Their purpose is to provide an extra layer of defense if you accidentally step on a live wire or make contact with an energized object. Primary protection always involves de-energizing circuits, lock-out/tag-out procedures, and using properly insulated tools.

The Critical Role of Dry Conditions

The EH standard test is conducted under dry conditions. Water is an excellent conductor of electricity.

If your boots are wet, or you are standing on a wet surface, the insulating properties of the sole can be compromised or completely bypassed. Water can create a path for electricity to travel around the boot's sole to the ground, rendering the protection ineffective.

Understanding the Limitations and Pitfalls

Trusting your equipment requires knowing its limits. EH footwear is highly effective for its intended purpose, but misunderstanding its limitations can be dangerous.

Not Designed for Static Control

EH footwear should never be confused with Static Dissipating (SD) or Conductive footwear. They serve opposite functions.

- EH boots insulate you from the ground to protect against shock.

- SD boots connect you to the ground to prevent the buildup of static electricity, which can damage sensitive electronics or ignite flammable materials.

Wearing EH boots in an environment that requires static control is a serious safety violation.

Wear and Tear is a Critical Failure

Daily inspection is not optional; it is essential. Before each use, you must check the soles and heels for:

- Deep cuts or punctures

- Embedded metal or conductive objects

- Excessive wear that has thinned the sole

Any breach in the integrity of the sole means the boot is no longer reliably EH-rated.

Employer Responsibility

According to OSHA guidelines, if a workplace hazard assessment identifies a risk of electric shock, the employer is responsible for providing appropriate PPE, such as EH footwear, at no cost to the employee.

How to Apply This to Your Role

Your safety depends on matching the equipment to the specific hazards of your job.

- If your primary focus is managing a safety program: Your priority is to conduct a thorough electrical hazard assessment and ensure your team is not only equipped with certified EH footwear but is also trained on daily inspection and its limitations.

- If your primary focus is personal safety in a dry environment: Rely on EH boots as a crucial secondary defense, but always inspect the soles for damage or embedded objects before entering a potentially hazardous area.

- If your primary focus is working in wet or damp conditions: Recognize that standard EH boots will not provide reliable protection, and you must depend entirely on primary safety protocols like de-energizing circuits.

Ultimately, EH-rated footwear is a vital piece of safety equipment, but its protection is only as strong as your understanding of how to maintain and use it correctly.

Summary Table:

| Requirement | Specification | Key Consideration |

|---|---|---|

| Voltage Test | 18,000 volts at 60 Hz for 1 minute | Simulates worst-case contact with live circuits. |

| Current Leakage | Must not exceed 1.0 milliampere | Ensures minimal, non-hazardous current flow. |

| Sole Integrity | Must be free of punctures, cuts, and excessive wear | A single breach can completely negate protection. |

| Primary Use Case | Secondary source of protection in dry conditions | Not for direct work on live circuits or wet environments. |

Ensure Your Team's Safety with Certified EH Footwear

As a large-scale manufacturer, 3515 produces a comprehensive range of certified EH-rated footwear for distributors, brand owners, and bulk clients. Our production capabilities encompass all types of safety boots and shoes designed to meet stringent EH standards, providing reliable secondary protection against electrical hazards.

Partner with us to equip your workforce with durable, compliant safety footwear.

Contact us today for a consultation and see how we can support your safety program.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Premium KPU Injection Athletic Style Safety Shoes

- Premium Grain Leather Safety Boots for Bulk Supply

- Custom Wholesale Leather Safety Boots Direct Factory Manufacturing

People Also Ask

- Why can metal protective toecaps become a risk factor for dorsal foot ulcers? Learn to Prevent Pressure Point Injuries

- How do professional construction boots improve operational efficiency? Boost Site Productivity with Advanced Footwear

- What are the primary protective functions of professional Safety Boots within the automotive maintenance process?

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- What core protection features do industrial-grade Safety Shoes provide? Key Safety Standards for Infrastructure Sites