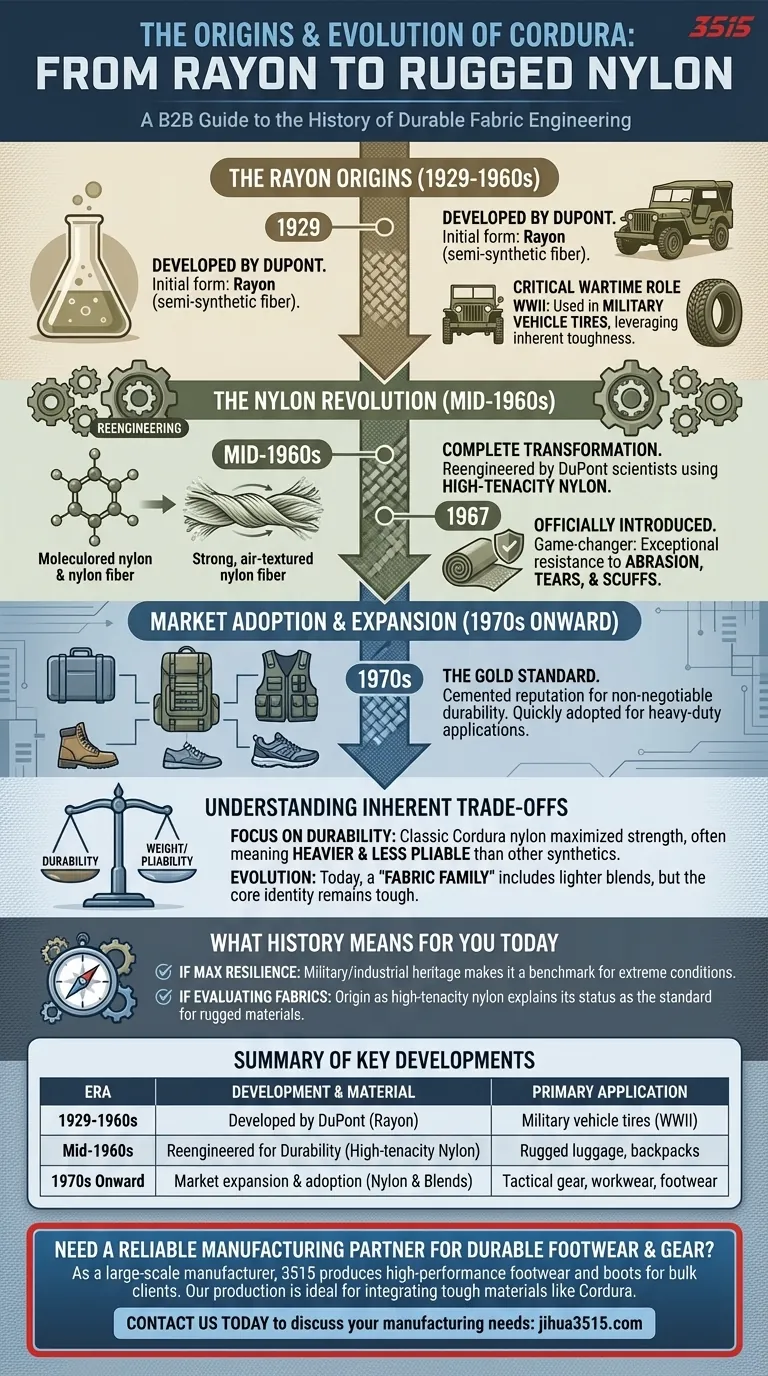

Originally developed by DuPont in 1929, Cordura began its life as a type of rayon. The fabric we recognize today for its exceptional toughness was born in the mid-1960s when it was completely reengineered into a high-tenacity, air-textured nylon, fundamentally changing its properties and its place in the market.

Cordura's reputation for unparalleled durability is not a marketing claim but the direct result of a pivotal shift in its history: its transformation from a standard synthetic into a purpose-built nylon engineered to meet demanding military and industrial standards.

The Two Eras of Cordura

Cordura's history can be understood in two distinct phases: its early life as a rayon-based material and its rebirth as the high-performance nylon that built its legacy.

The Rayon Origins (1929)

The Cordura story begins with its creation by DuPont. In this initial form, it was a type of rayon, a semi-synthetic fiber.

A Critical Wartime Application

During World War II, this early version of Cordura found a crucial role in the war effort. Its durability was leveraged for use in military vehicle tires, showcasing its inherent toughness even before its most significant evolution.

The Nylon Revolution

The mid-20th century marked a complete transformation for the material. This was not a minor update but a fundamental reengineering that created the Cordura brand as we know it.

Reengineering for Peak Performance (Mid-1960s)

In the 1960s, DuPont's scientists developed a new, far more robust version of Cordura. By using high-tenacity nylon fibers, the fabric gained exceptional resistance to abrasion, tears, and scuffs.

This new nylon-based material was officially introduced in 1967. Its durability was a game-changer for many industries.

Market Adoption and Expansion (1970s Onward)

By the 1970s, Cordura's reputation was cemented. It became the gold standard for applications where durability was non-negotiable.

It was quickly adopted for heavy-duty luggage, rugged backpacks, tactical military gear, workwear, and performance footwear, establishing its identity as a fabric built to last.

Understanding the Inherent Trade-offs

Cordura's historical development was driven by a single-minded pursuit of durability, which naturally involves specific trade-offs.

The Focus on Durability Above All Else

The classic Cordura nylon fabrics were engineered for maximum strength and abrasion resistance. This often meant they were heavier and less pliable than other synthetics designed for comfort or light weight.

The Evolution into a Fabric Family

Today, "Cordura" is a brand that encompasses a wide range of fabrics, not just the original heavy nylon. The portfolio now includes lighter blends and materials tailored for different needs, but the brand's core identity remains rooted in its tough, historical origins.

What Cordura's History Means for You Today

Understanding this historical journey from a basic rayon to a military-grade nylon provides critical context for why the fabric is so trusted.

- If your primary focus is maximum resilience: Cordura's military and industrial heritage ensures it is a benchmark choice for gear that must withstand extreme abrasion and harsh conditions.

- If you are evaluating different "durable" fabrics: Knowing its origin as a high-tenacity nylon explains why it often serves as the standard against which other rugged materials are measured.

Its history is a direct reflection of its purpose: engineered resilience that you can rely on.

Summary Table:

| Era | Key Development | Primary Material | Key Application |

|---|---|---|---|

| 1929-1960s | Developed by DuPont | Rayon | Military vehicle tires (WWII) |

| Mid-1960s | Reengineered for durability | High-tenacity Nylon | Rugged luggage, backpacks |

| 1970s Onward | Market expansion & adoption | Nylon & Blends | Tactical gear, workwear, footwear |

Need a reliable manufacturing partner for durable footwear and gear?

As a large-scale manufacturer, 3515 produces a comprehensive range of high-performance footwear and boots for distributors, brand owners, and bulk clients. Our production capabilities, ideal for integrating tough materials like Cordura, ensure your products are built to last.

Contact us today to discuss your manufacturing needs and leverage our expertise in durable product creation.

Visual Guide

Related Products

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Lightweight Safety Shoes for Wholesale & Bulk Orders

- Wholesale Safety Footwear Manufacturer for Bulk & Custom OEM Orders

- Custom Safety Shoe Manufacturer for Wholesale & OEM Brands

- Premium Flame-Retardant Waterproof Safety Boots and Shoes

People Also Ask

- What role does Digital Twin technology play in the planning of footwear production lines? Optimize Manufacturing Now

- What precautions should be taken before waterproofing suede or nubuck leather boots? Protect Your Investment

- What benefits does a 3D-printed enclosure provide for outdoor wearable gait analysis? Enhance Precision & Wearability

- Which boot areas require special cleaning attention? Focus on soles and crevices for longevity.

- What technical challenge does the Bi-LSTM address in fall-detection? Enhancing Temporal Accuracy in Motion Sensing

- What are the benefits of regular boot maintenance? Extend Boot Life & Enhance Safety

- What is PVC, and how is it produced? A Guide to Cost-Effective, Durable Polymer Manufacturing

- What are the advantages of using logistics management software for footwear inventory? Boost Efficiency at Scale