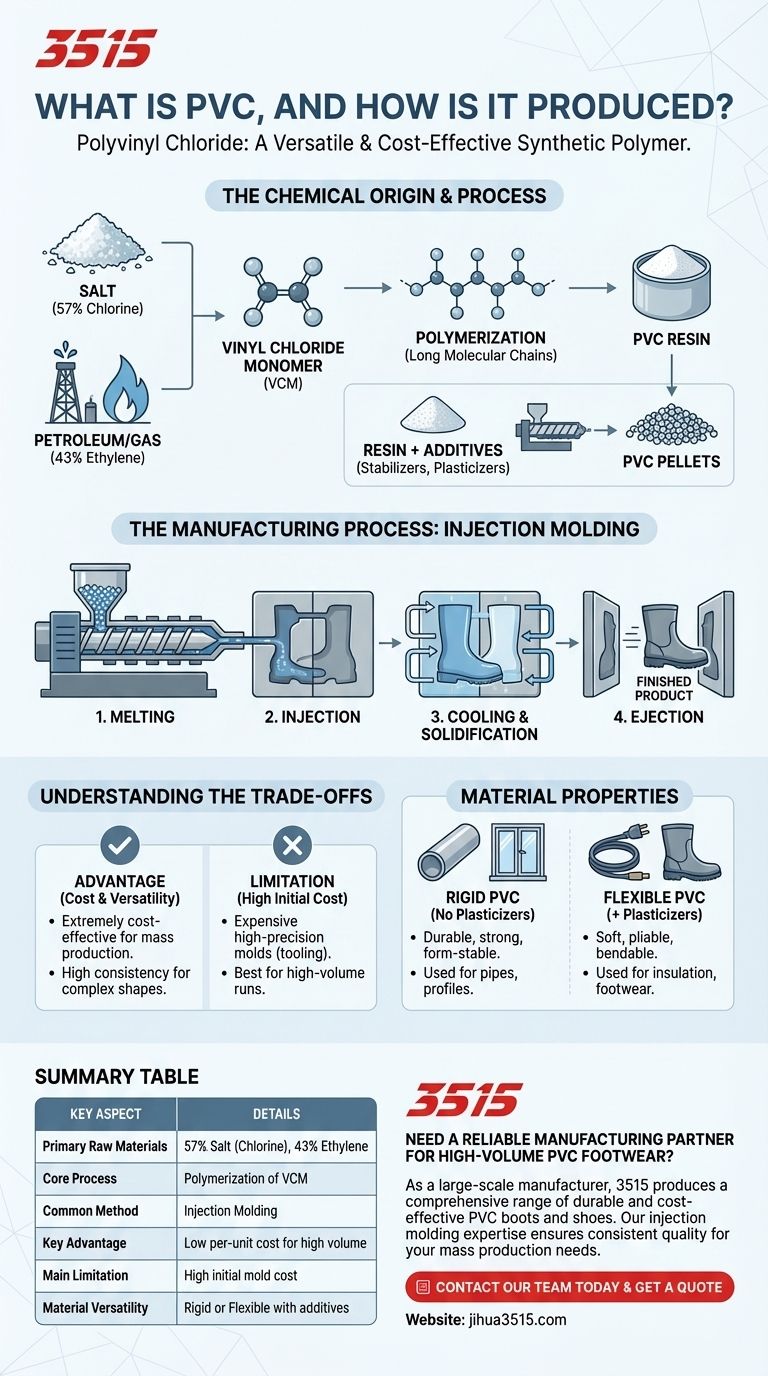

At its core, polyvinyl chloride (PVC) is a versatile and cost-effective synthetic plastic polymer. It is not simply derived from petroleum, but is uniquely created from two common resources: 57% from industrial-grade salt (chlorine) and 43% from petroleum or natural gas (ethylene). For manufacturing, PVC is typically melted and forced into a shaped cavity in a process known as injection molding.

PVC is a synthetic plastic valued for its durability and low production cost. Its creation involves a two-stage process: first, a chemical synthesis from salt and ethylene to create the polymer, and second, a physical manufacturing process like injection molding to shape it into finished products.

Deconstructing PVC: From Raw Materials to Polymer

To truly understand PVC, we must first look at its fundamental chemistry. The material's properties and applications are a direct result of how its basic molecular building blocks are assembled.

The Building Blocks: Salt and Ethylene

Unlike many other plastics that are purely petroleum-based, PVC has a unique dual origin. The process starts with chlorine, which is produced from common salt, and ethylene, which is derived from natural gas or oil.

These two components are chemically reacted to create a gas called vinyl chloride monomer (VCM). This monomer is the essential building block of the final PVC material.

The Chemical Process: Polymerization

The next step is polymerization. In this high-pressure process, individual vinyl chloride monomer molecules are linked together to form long, repeating molecular chains.

The result of this process is a fine white powder or resin known as polyvinyl chloride. This raw resin is the base material for all PVC products.

From Resin to Pellets

In its raw resin form, PVC is not yet ready for manufacturing. It is almost always blended with additives like stabilizers (for durability) or plasticizers (for flexibility). This compound is then heated and extruded into small, uniform pellets, which are easy to transport, melt, and process.

The Manufacturing Process: Injection Molding Explained

The most common method for turning PVC pellets into a finished product, such as a work boot or pipe fitting, is injection molding. This industrial process is prized for its speed, precision, and efficiency at scale.

Step 1: Melting the Pellets

Solid PVC pellets are fed into the barrel of an injection molding machine. Heaters along the barrel and friction from a large rotating screw melt the pellets into a homogenous, molten liquid.

Step 2: Injection into the Mold

Once enough molten plastic is ready, it is injected under extremely high pressure into a custom-made metal mold. The liquid PVC completely fills the internal cavity of this mold, which is the exact inverse shape of the final product.

Step 3: Cooling and Solidification

The mold is cooled, typically with circulating water, which causes the molten PVC to quickly solidify and harden. This allows the plastic to perfectly retain the detailed shape of the mold cavity.

Step 4: Ejection of the Part

Once the part is solid, the mold opens and the finished product is ejected. This entire cycle can take anywhere from a few seconds to a couple of minutes, allowing for the rapid production of thousands or millions of identical items.

Understanding the Trade-offs

While powerful, the use of PVC and injection molding involves specific advantages and limitations that are critical to understand when selecting a material.

The Advantage: Cost and Versatility

Injection molding PVC is an exceptionally cost-effective method for mass-producing parts. The speed of the process and the low cost of the raw material keep the per-unit price very low, and it can create highly complex and durable shapes with great consistency.

The Limitation: High Initial Tooling Costs

The primary trade-off is the cost of the mold itself. These molds are high-precision tools made from hardened steel and can be extremely expensive to design and manufacture. This makes the process best suited for high-volume production runs that can amortize the initial investment.

The Material Properties: Flexibility is Engineered

PVC can be formulated to be either rigid or flexible. Rigid PVC is used for things like pipes and window frames. By adding plasticizers, it becomes soft and pliable, making it ideal for products like electrical cable insulation or waterproof boots.

Making the Right Choice for Your Goal

Understanding the fundamentals of PVC production allows you to make an informed decision based on your specific project needs.

- If your primary focus is mass production of complex, durable parts: The low per-unit cost and high repeatability of PVC injection molding make it an ideal choice.

- If your primary focus is low-volume production or prototyping: The high upfront mold cost makes injection molding unsuitable; consider other manufacturing methods like 3D printing or machining.

- If your primary focus is material sustainability: Acknowledging PVC's dual origin from both fossil fuels (ethylene) and common salt (chlorine) is essential for any life-cycle assessment.

By understanding how a material is created and formed, you are empowered to select the right solution for your technical challenge.

Summary Table:

| Key Aspect | Details |

|---|---|

| Primary Raw Materials | 57% Salt (Chlorine), 43% Ethylene (from oil/gas) |

| Core Process | Polymerization of Vinyl Chloride Monomer (VCM) |

| Common Manufacturing Method | Injection Molding |

| Key Advantage | Extremely low per-unit cost for high-volume production |

| Main Limitation | High initial cost for precision molds |

| Material Versatility | Can be formulated as rigid or flexible with additives |

Need a reliable manufacturing partner for high-volume PVC footwear?

As a large-scale manufacturer, 3515 produces a comprehensive range of durable and cost-effective PVC boots and shoes for distributors, brand owners, and bulk clients. Our expertise in injection molding ensures consistent quality and efficiency for your mass production needs.

Contact our team today to discuss your project and get a quote.

Visual Guide

Related Products

- Safety Footwear Wholesale Manufacturer for Custom OEM/ODM Production

- Durable Canvas Work Shoes with Rubber Lug Sole | Wholesale Manufacturer

- Premium Safety Shoes with Rotating Buckle Safety Sneakers

- Durable Rubber-Soled Utility Shoes for Wholesale & Custom Brand Manufacturing

- Premium Wholesale Tactical Style Safety Shoes Boots with Quick Lacing

People Also Ask

- What are OSHA approved shoes? Understanding the Correct Standards for Workplace Safety

- Is safety-toe as good as steel toe? Choose the Right Protection for Your Job

- What are the cultural perspectives on wearing shoes in the house? A Guide to Home Etiquette & Hygiene

- Is it normal to wear shoes in the house? A Guide to Hygiene, Comfort & Culture

- What do heavy duty boots do? Protect Your Feet in Demanding Work Environments